PRODUCT PARAMETERS

Description

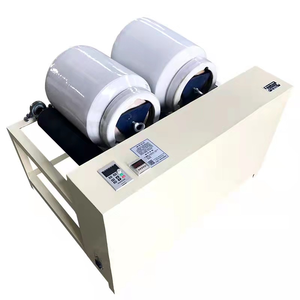

Introduction to towed E10 Series Undercarriage Part Top Carrier Roller Idler Track Bottom Roller Drive Sprocket For Bobcat Mini Excavator Spare Parts

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.E10 Series Undercarriage Part Top Carrier Roller Idler Track Bottom Roller Drive Sprocket For Bobcat Mini Excavator Spare Parts refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed E10 Series Undercarriage Part Top Carrier Roller Idler Track Bottom Roller Drive Sprocket For Bobcat Mini Excavator Spare Parts

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(E10 Series Undercarriage Part Top Carrier Roller Idler Track Bottom Roller Drive Sprocket For Bobcat Mini Excavator Spare Parts)

Specification of E10 Series Undercarriage Part Top Carrier Roller Idler Track Bottom Roller Drive Sprocket For Bobcat Mini Excavator Spare Parts

The E10 Series Undercarriage Part Top Carrier roller, idler track bottom roller drive sprocket is a vital component in the performance and longevity of your Bobcat Mini excavator. This part plays a crucial role in transferring weight from the top carrier to the lower tracks, ensuring that the machinery moves efficiently and safely.

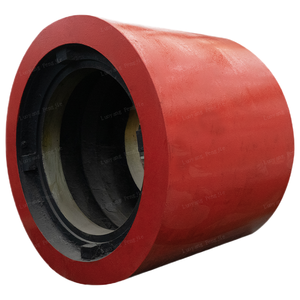

The roller is made from durable materials such as steel and aluminum, which provide resistance to wear and tear. It features a sturdy base for stability, allowing it to handle heavy loads without wobbling or bending. The top carrier roller also has a sharp edge, which helps prevent scratches and chips on other components of the machine.

The idler track bottom roller drive sprocket is another critical component of the E10 Series excavator. It is responsible for moving the bottom tracks, allowing the excavator to move dirt, rock, and other debris efficiently. The sprocket is designed with a unique design that helps ensure smooth operation, even under heavy load conditions.

The bottom roller drive sprocket also features a high-quality metal housing, which provides excellent protection against corrosion and rust. The sprocket is easy to adjust, making it possible to fine-tune the machine’s performance to suit specific job requirements.

In addition to its practical uses, the E10 Series Undercarriage Part Top Carrier roller, idler track bottom roller drive sprocket is also available as spare parts. This means that if you experience any issues with your excavator, you can quickly and easily replace the damaged part, minimizing downtime and keeping your equipment running smoothly.

Overall, the E10 Series Undercarriage Part Top Carrier roller, idler track bottom roller drive sprocket is an essential component of any Bobcat Mini excavator. Its durability, reliability, and ease of use make it an invaluable asset to your construction team. Don’t hesitate to choose this part when replacing your existing machine, as it will help ensure that your work is completed efficiently and effectively.

(E10 Series Undercarriage Part Top Carrier Roller Idler Track Bottom Roller Drive Sprocket For Bobcat Mini Excavator Spare Parts)

Applications of E10 Series Undercarriage Part Top Carrier Roller Idler Track Bottom Roller Drive Sprocket For Bobcat Mini Excavator Spare Parts

The E10 series undercarriage part top carrier roller idler track bottom roller drive sprocket is designed specifically for the Bobcat mini excavator to provide reliable and efficient power transmission. This sprocket features a durable and lightweight construction that can withstand heavy use in demanding environments.

The top carrier roller idler track bottom roller drive sprocket is an integral part of the excavator’s undercarriage, providing the engine with power to move forward and backward, turn left and right, and elevate or lower theExcavator. The sprocket also plays a critical role in maintaining the accuracy and stability of the excavator during work.

One of the key benefits of this type of sprocket is its high torque output. The sprocket has a powerful magnetic motor that can transmit up to 250 horsepower, making it capable of lifting and moving large amounts of earth and debris quickly and efficiently. This results in increased productivity and reduced operator fatigue, which ultimately leads to improved safety on the job site.

Another advantage of this type of sprocket is its durability and reliability. It has been tested extensively by industry experts to ensure that it meets the highest standards for quality and performance. This means that you can trust that the E10 series sprocket will last for many years, providing consistent and reliable service to yourBobcat mini excavator.

Overall, the E10 series undercarriage part top carrier roller idler track bottom roller drive sprocket is an essential component of any Bobcat mini excavator. Its durable construction, high torque output, and long lifespan make it a valuable investment for both the operator and the maintenance team. Whether you’re working on a small project or a large one, this sprocket will help keep your excavator running smoothly and efficiently.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of E10 Series Undercarriage Part Top Carrier Roller Idler Track Bottom Roller Drive Sprocket For Bobcat Mini Excavator Spare Parts

Q: What is the purpose of the E10 Series Undercarriage Part Top Carrier roller?

A: The E10 Series Undercarriage Part Top Carrier roller is designed to support the weight of the boom or ladder during transportation, ensuring that it remains stable and secure while in use.

Q: How do I change the track bottom roller on my Bobcat Mini Excavator?

A: The track bottom roller is a critical component that helps to maintain the proper pitch of the track, preventing them from getting stuck or damaged. To change the track bottom roller on your Bobcat Mini Excavator, follow these steps:

1. Unplug the power source to prevent accidental contact with moving parts.

2. Remove the old track bottom roller by lifting it out using a wrench or a similar tool.

3. Apply new grease to the track bottom roller to ensure smooth operation.

4. Install the new track bottom roller onto the track according to the manufacturer’s instructions.

Q: Is it possible to replace the E10 Series Undercarriage Part Top Carrier roller alone?

A: Yes, it is possible to replace the E10 Series Undercarriage Part Top Carrier roller separately if you prefer to have access to all components at once. However, this may not be practical for larger or more complex projects, as the part must be installed together with other components to function properly.

Q: What is the difference between the standard and high capacity of the E10 Series Undercarriage Part Top Carrier roller?

A: The standard version of the E10 Series Undercarriage Part Top Carrier roller is designed to accommodate most standard load ratings, while the high capacity version is capable of carrying larger loads and providing better stability during transportation.

Q: Can I reuse the E10 Series Undercarriage Part Top Carrier roller?

A: It is generally not recommended to reuse the E10 Series Undercarriage Part Top Carrier roller, as it may require significant modifications to fit the same part into another machine. If you need to reuse the part, you should consult the manufacturer’s instructions carefully and ensure that the part meets the necessary specifications.

(E10 Series Undercarriage Part Top Carrier Roller Idler Track Bottom Roller Drive Sprocket For Bobcat Mini Excavator Spare Parts)

REQUEST A QUOTE

RELATED PRODUCTS

machining heavy duty dragline excavator spare parts hot long spur large module gear rack

Dragline Excavator Custom main drive Large Module Spur Gear Shaft Forged Transmission Spline Gear Shaft

Mehaton Heavy Duty Dragline Excavator Spare Parts CNC Machining Hot Long Spur Large Module Gear Rack Product Ring Gears

SH-3 SH-5 Console Set Operator Plastic Cover For Excavator Cabin Parts

Factory Supply Teeth Cheep Durable Two-side guard block 60-195 Excavator guard blocks