PRODUCT PARAMETERS

Description

Brief introduction of High manganese casting ball mill parts mill impact liner plate and blow bar

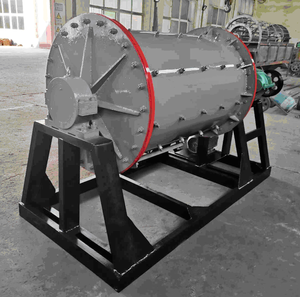

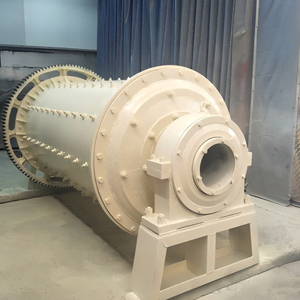

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. High manganese casting ball mill parts mill impact liner plate and blow bar refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of High manganese casting ball mill parts mill impact liner plate and blow bar

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(High manganese casting ball mill parts mill impact liner plate and blow bar)

Specification of High manganese casting ball mill parts mill impact liner plate and blow bar

High manganese cast balls and mill impact liner plates, as well as blow bars, are essential components for the operation of ball mills in mining applications. These parts ensure that the balls and impact liner plates are in the correct condition to maximize grinding efficiency.

The high manganese cast balls are made from a material with a high carbon content, which provides excellent strength and durability. They can withstand severe wear and tear during operation, ensuring reliable performance over extended periods. The casting process involves pouring molten metal into a mold, which allows the ball to be shaped and hardened to a specific size and shape.

Impact liner plates are used to prevent attrition of material between the balls and the chamber walls. They are typically made from a material such as stainless steel or titanium, which is strong and durable. The impact liner plates are mounted on top of the balls and rotate around them, allowing for efficient grinding of ore. A proper balance of weight distribution is critical to achieving optimal grinding efficiency.

Blow bars are used to remove excess material from the balls and impact liner plates before they enter the mill. They consist of a series of narrow tubes connected by blades at the end. As the ball and impact liner plates move through the mill, they pass through the blades, removing the excess material as they do. This prevents the balls and impact liner plates from becoming clogged or overheated, improving their overall lifespan.

In conclusion, high manganese cast balls and mill impact liner plates, as well as blow bars, are critical components of ball mills in mining applications. They ensure reliable performance by providing strong materials for the balls and impact liner plates, preventing attrition, and removing excess material from the mill. By using high-quality materials and properly designed components, manufacturers can produce mill equipment that performs at maximum efficiency and reduces operating costs.

(High manganese casting ball mill parts mill impact liner plate and blow bar)

Applications of High manganese casting ball mill parts mill impact liner plate and blow bar

High manganese casting balls, impact liners plates, and blow bars are important components in many industrial processes, particularly those involving mining, metal production, and chemical reactions.

Manganese casting balls are used to grind materials by applying pressure on them until they become very small, making it easier to process and refine the material. They are typically made from high manganese steel and can withstand severe impacts without degrading or breaking.

Impact liners plates are also commonly used in applications where force is applied on the ground. These plates are made from materials such as steel or ceramic and are designed to absorb and distribute stress throughout the material, preventing it from cracking or splitting under pressure. They are often used in applications such as concrete mixing plants and power plant foundations.

Blow bars are used to remove molten metal from melted areas of a production line. The molten metal is forced through a blast furnace or another type of heating unit, where it is converted into a fine powder. This fine powder is then collected and directed away from the machine to be used for further processing or storage.

Overall, high manganese casting balls, impact liners plates, and blow bars play critical roles in ensuring the efficient and effective operation of industrial processes. By using these components properly, manufacturers can produce high-quality products that meet or exceed customer expectations.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High manganese casting ball mill parts mill impact liner plate and blow bar

1. What is high manganese casting ball mill parts?

High manganese casting balls are made from a mixture of iron and manganese, which provide excellent wear resistance and improve the strength of the cast balls.

2. How do high manganese casting ball mill parts work?

When high manganese casting balls are inserted into the ball mill, they help to reduce friction and increase power output. The impact plates of the ball mill then compress the balls and break them down into smaller pieces, further improving the grinding efficiency of the material being processed.

3. Are high manganese casting balls suitable for all types of materials?

Yes, high manganese casting balls are suitable for processing a wide range of materials including minerals, coal, steel, and hasil

(High manganese casting ball mill parts mill impact liner plate and blow bar)

REQUEST A QUOTE

RELATED PRODUCTS

Competitive Wear Resistant Steel Casting Liner Plates for Crusher Machinery OEM Ball Mill Wear Parts

cement ball mill machine stone grinding with ball mill parts

Large Capacity Ball Mill 3200X4500 for Crushing Chrome Ore, Spare Parts Supply All Provided AC Motor South Africa 85000

Ball Mill Machine Gold Mining Ball Mill Spare Parts Equipment Portable Ceramic Ball Mill for Mining

Small Ball Mill Grinding Machine with New Motor Core Component Ball Mill Spare Parts