PRODUCT PARAMETERS

Description

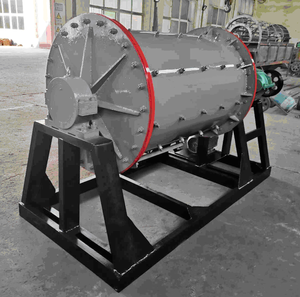

Brief introduction of Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500 refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500)

Specification of Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500

Ball mills, also known as ball mills or ball mill machine, are commonly used in various industries for grinding materials. A ball mill is a cylindrical grinding device made of a steel construction and consists of an input chamber where raw materials are placed, a rotating inner drum that contains balls, and an output chamber where the grind is recovered.

The specification of a ball mill varies depending on the type of material being ground and the size of the mill. For instance, a small ball mill with a diameter of 3mm to 6mm may be suitable for grinding flour, while a large ball mill with a diameter of 1200mm to 1800mm may be required for grinding cement.

In terms of gear aluminum powder ball mill, it is a versatile mill designed to process different types of materials such as coal, gold, and iron ore. The mill consists of a gear aluminum powder main drum, which is lined with gears made of aluminum powder. The rotating drum has a motor installed inside, which powers the mill.

The feed size of the ball mill is controlled using a control rod and a motorized gate system. The gate can be opened and closed to adjust the feed rate and ensure consistent operation. The rotation speed of the drum is adjusted using a variable frequency drive (VFD), which allows for smooth operation and maximum grinding efficiency.

The output size of the ball mill depends on the feed rate and the grind size. The output size can be up to 50 microns or larger, making it ideal for applications where high-quality particles are required. The ball mill can also be equipped with a separator to separate the fine powder from the rest of the material.

Overall, the specifications of the ball mill vary depending on the specific application. However, all ball mills have one thing in common: they are powerful tools for grinding materials efficiently and accurately. With their versatility and durability, ball mills are widely used in many industries for processing various types of materials.

(Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500)

Applications of Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500

Ball mill is widely used in various industries for grinding and milling operations. The ball mill consists of multiple parts, including the balls, grinding jar, gears, and aluminum powder. Here are some applications of ball mill 6 ball mill parts gear aluminum powder ball mill 1200*4500:

1. Grinding materials: Ball mills can be used to grind and mill a variety of materials, including grains, minerals, and chemicals.

2. Finishing processes: Ball mills are commonly used in the finishing process of paints, coatings, and other products. They help to smooth out the surface of the material being coated and ensure that it adheres properly.

3. Material processing: Ball mills are also used in the processing of metal powders, such as aluminum powder. By using a ball mill, the metal can be ground into fine particles, which can then be used in manufacturing processes.

4. Research and development: Ball mills are an essential tool for researchers and engineers who need to perform high-throughput experiments on small samples of materials.

5. Quality control: Ball mills are used to test the quality of products produced by other companies. This helps to ensure that the final product meets industry standards and is of high quality.

In conclusion, ball mills are versatile tools that can be used in a wide range of industries. From grinding and milling materials to finishing processes, they are an essential component of modern manufacturing processes. Whether you are working with grains, minerals, or metal powders, a ball mill can help you achieve your goals and produce high-quality products.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500

Q: What material does the gear aluminum powder ball mill use?

A: The gear aluminum powder ball mill is made from high-quality aluminum alloy, which provides excellent wear resistance and durability. It can withstand harsh operating conditions, including temperatures up to 500°C, without degrading or breaking down.

Q: How many balls do I need for a 1200×4500 ball mill?

A: The number of balls needed for a ball mill depends on the specific application and the desired throughput. Generally speaking, you will need at least 8-12 balls in a ball mill to ensure adequate grinding efficiency and stability.

Q: What is the difference between a ball mill and a raymond mill?

A: A ball mill uses balls as grinders, while a raymond mill uses an electrical motor to rotate the balls through a die cavity.Ball mills are typically used for fine grinding, such as grinding powders and grinds, while raymond mills are more commonly used for medium-to-dense grinding, such as grinding coal and cement.

Q: What are the advantages of using a ball mill over a raymond mill?

A: One advantage of using a ball mill over a raymond mill is that it has lower energy consumption compared to the former. This means that less electricity needs to be supplied to operate the mill, resulting in reduced costs and environmental impact.

Q: Are there any safety precautions to keep in mind when operating a ball mill?

A: Yes, there are several safety precautions that should be taken when operating a ball mill, including wearing appropriate personal protective equipment (PPE) such as goggles and gloves, avoiding using wet hands or tools near the machine, and maintaining proper ventilation to prevent the buildup of fumes or dust.

Q: Can I use my own balls instead of purchasing them from a supplier?

A: No, it is not recommended to use your own balls instead of purchasing them from a supplier. Using your own balls can lead to inconsistent grinding performance, poor quality control, and increased maintenance costs. It is important to follow manufacturer recommendations and select the appropriate type of balls based on the specific requirements of your application.

(Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500)

REQUEST A QUOTE

RELATED PRODUCTS

High Capacity ball mill machine dry wet ball stone grinding gold ball mill catalytic converter parts and accessories

Factory custom mining equipment ball mill drive parts accessories Hollow shaft

Ball Mill Machine Gold Mining Ball Mill Spare Parts Equipment Portable Ceramic Ball Mill for Mining

Casting High Quality and Long Use Time Ball Mill Diaphragm Excellent Performance Ball Mill Spare Parts Ball Mill Liners

Mill Machine Spare Part Ball Mill Pinion Shaft Mining Mineral Equipment Parts