PRODUCT PARAMETERS

Description

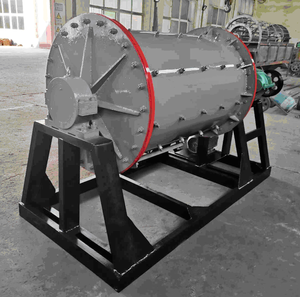

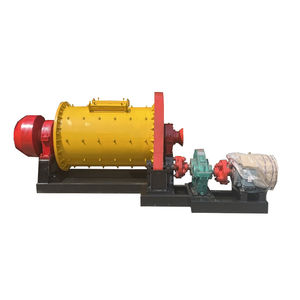

Brief introduction of cement ball mill machine stone grinding with ball mill parts

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. cement ball mill machine stone grinding with ball mill parts refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of cement ball mill machine stone grinding with ball mill parts

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(cement ball mill machine stone grinding with ball mill parts)

Specification of cement ball mill machine stone grinding with ball mill parts

Cement Ball Mill Machine Stone Grinding With Ball Mill Parts is a specialized machinery designed to grind and refine stones into fine powders. This machine utilizes high-pressure and rotation forces to break down the hard, dense minerals in the raw material into smaller, more manageable particles.

The first step in using a cement ball mill machine is to select the appropriate type of stone for grinding. Different types of stones have different characteristics that affect their behavior during grinding, such as density, hardness, and moisture content. Therefore, it is essential to choose the right type of stone to achieve the desired grinding results.

Once the stone has been selected, the next step is to properly configure the machine’s components. This includes setting the correct size and shape of the balls used in the mill, determining the appropriate pressure and speed settings, and ensuring that all the components are properly lubricated and cleaned.

One of the key features of a cement ball mill machine is its ability to produce high-quality powder at low operating costs. This is achieved through careful selection of materials, proper design and configuration of the machine, and regular maintenance and cleaning of all components.

In addition to its economic benefits, a cement ball mill machine also provides environmental advantages. By reducing the amount of waste generated during the grinding process, this equipment helps to reduce the overall environmental impact of industrial activities.

Overall, the specification of cement ball mill machine stone grinding with ball mill parts is an essential aspect of its operation. Properly configured and maintained, these machines can provide reliable and efficient grinding capabilities that can help to improve the quality and quantity of stone produced.

(cement ball mill machine stone grinding with ball mill parts)

Applications of cement ball mill machine stone grinding with ball mill parts

Cement ball mill is an essential equipment used in cement production plants for grinding raw materials into fine particles, which aid in the transportation and storage of concrete.

One of the primary applications of cement ball mill machine is in the manufacturing of cement. The ball mill machines are used to grind cement by adding moisture and air to the raw materials. The resulting mixture is then passed through the grinding chamber where it is crushed and ground into smaller particles. This process helps in achieving the required particle size for various applications such as construction, road building, and urban planning.

Another important application of cement ball mill machine is in the mining industry. The ball mill machines are used to grind minerals like coal, iron ore, and salt to extract their valuable minerals. The minerals can be used in the production of cement, fertilizers, and other products.

In addition to these industrial applications, cement ball mill machine is also used in the agricultural industry for grinding grains and cereals. It is used in the preparation of flour, semolina, and other flour products. The powder produced by the ball mill machine is high in quality and is used in food processing,, and many other applications.

Overall, cement ball mill machine is a versatile and powerful equipment that has a wide range of applications in various industries. Its ability to produce small and uniform particles of raw materials makes it ideal for a variety of applications, from industrial use to agricultural and even in the medical field.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of cement ball mill machine stone grinding with ball mill parts

1. What is a cement ball mill machine?

A cement ball mill is a type of grinding equipment used in the manufacturing process of cement and other clinker products. It consists of a rotating steel ball that grinds limestone or dolomite into smaller particles, which are then passed through a circuit of openings to produce fine-grained clinker.

2. How does a cement ball mill work?

The cement ball mill works by circulating water and air within a cylindrical chamber called the grinding chamber. As the balls rotate inside the grinding chamber, they collide with the ground material, causing it to break down into smaller pieces. The produced is referred to as cement clinker, which can be used for various purposes such as construction, civil engineering, and power generation.

3. What types of cement ball mills are available?

There are several types of cement ball mills available, including horizontal and vertical axis ball mills. Horizontal axis ball mills have a shorter diameter than vertical axis ball mills, making them easier to install on-premises. Vertical axis ball mills have a longer diameter than horizontal axis ball mills, but they require less maintenance and have higher production capacity.

4. What are the benefits of using a cement ball mill for grinding limestone?

Limestone is a common raw material used in the cement industry, and it is often ground using a cement ball mill. Using a cement ball mill for grinding limestone has several benefits. Firstly, it allows for a high degree of fineness, resulting in better quality cement clinker. Secondly, it reduces energy consumption and emissions compared to traditional grinding methods. Finally, it saves time and labor costs by eliminating the need for manual operation.

5. Are there any safety precautions to take when working with a cement ball mill?

Yes, there are several safety precautions to take when working with a cement ball mill. Firstly, proper personal protective equipment (PPE) should be worn, including hard hats, gloves, and safety glasses. Secondly, all machinery should be properly maintained and inspected before use to ensure that it is functioning correctly. Thirdly, workers should be trained on the safe handling and operation of the equipment, and emergency procedures should be outlined in case of an accident. Finally, all employees should be aware of the potential hazards associated with the equipment and take appropriate measures to mitigate those risks.

(cement ball mill machine stone grinding with ball mill parts)

REQUEST A QUOTE

RELATED PRODUCTS

OEM customize cast alloy ball mill liners wear resistant lining plate spare parts

Wear resistant non-standard Heavy Machinery Ball Mill Parts large Casting Liner Plate

Rotary kiln and cement ball mill spare pasts large steel spur gear wheel and ring gear casting girth gear

heavy duty mining ball mill spare part 42CrMo steel hollow shaft

Low worth buying products Mining Grinding Mill Trommel Scrubber Wear Parts Rubber Ball Mill Liner For