PRODUCT PARAMETERS

Description

Introduction to towed Dragline Excavator custom Nonstandard Casting 35#Transmission Large size Gear Shaft Coupling

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Dragline Excavator custom Nonstandard Casting 35#Transmission Large size Gear Shaft Coupling refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Dragline Excavator custom Nonstandard Casting 35#Transmission Large size Gear Shaft Coupling

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

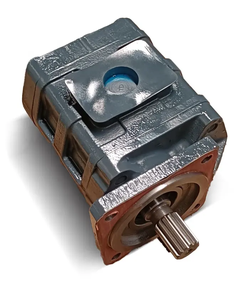

(Dragline Excavator custom Nonstandard Casting 35#Transmission Large size Gear Shaft Coupling)

Specification of Dragline Excavator custom Nonstandard Casting 35#Transmission Large size Gear Shaft Coupling

The Dragline Excavator Custom Nonstandard Casting 35# Transmission Large Size Gear Shaft Coupling is a high-performance, precision-engineered component designed to meet the demanding requirements of heavy-duty industrial applications. This custom casting is specifically tailored for dragline excavators, ensuring optimal performance, durability, and reliability in harsh operating conditions. The gear shaft coupling is manufactured using 35# steel, a high-quality material known for its excellent strength, toughness, and wear resistance. This makes it ideal for transmitting high torque and handling heavy loads, which are common in dragline excavator operations.

The large size gear shaft coupling is designed to accommodate the unique specifications of nonstandard transmission systems, providing a perfect fit and seamless integration with existing machinery. Its robust construction ensures minimal wear and tear, even under continuous use, reducing maintenance costs and downtime. The coupling features precise machining and finishing, ensuring smooth operation and efficient power transmission. This is critical for maintaining the performance and productivity of dragline excavators, which are often used in mining, construction, and other heavy industries.

One of the standout features of this gear shaft coupling is its customizability. It can be tailored to meet specific dimensional and functional requirements, making it a versatile solution for a wide range of applications. Whether you need a unique design, specific tolerances, or specialized surface treatments, this product can be customized to suit your needs. Additionally, the coupling undergoes rigorous quality control and testing to ensure it meets the highest industry standards, providing peace of mind and long-term reliability.

In summary, the Dragline Excavator Custom Nonstandard Casting 35# Transmission Large Size Gear Shaft Coupling is a durable, high-performance component designed for heavy-duty applications. Its customizability, precision engineering, and use of high-quality materials make it an excellent choice for industries that demand reliability and efficiency in their equipment. Whether you’re operating in mining, construction, or other challenging environments, this gear shaft coupling is built to deliver exceptional performance and withstand the toughest conditions.

(Dragline Excavator custom Nonstandard Casting 35#Transmission Large size Gear Shaft Coupling)

Applications of Dragline Excavator custom Nonstandard Casting 35#Transmission Large size Gear Shaft Coupling

The Applications of Dragline Excavator Custom Nonstandard Casting 35# Transmission Large Size Gear Shaft Coupling are vast and critical in heavy-duty industries, particularly in mining, construction, and large-scale earthmoving operations. These custom-engineered components are designed to meet the rigorous demands of dragline excavators, which are among the largest and most powerful machines used in surface mining and excavation projects. The 35# transmission large size gear shaft coupling plays a pivotal role in ensuring the efficient transfer of power and torque between the excavator’s engine and its moving parts, such as the boom, bucket, and hoist systems.

One of the primary applications of this custom nonstandard casting is in the transmission system of dragline excavators, where it connects the gearbox to the drive shafts. This coupling must withstand extreme loads, high torque, and continuous operation under harsh environmental conditions, including exposure to dust, moisture, and temperature fluctuations. The use of 35# steel in its construction ensures exceptional strength, durability, and resistance to wear, making it ideal for heavy-duty applications.

Additionally, the large size gear shaft coupling is crucial for maintaining the alignment and synchronization of rotating components within the excavator. Its precise engineering minimizes vibration and reduces the risk of mechanical failure, thereby enhancing the overall performance and lifespan of the equipment. The custom nonstandard design allows for seamless integration with existing machinery, ensuring compatibility and reducing downtime during installation or maintenance.

In summary, the Applications of Dragline Excavator Custom Nonstandard Casting 35# Transmission Large Size Gear Shaft Coupling are indispensable in industries that rely on heavy machinery for large-scale operations. Its robust construction, precision engineering, and ability to withstand extreme conditions make it a vital component in ensuring the reliability, efficiency, and longevity of dragline excavators and similar equipment.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Dragline Excavator custom Nonstandard Casting 35#Transmission Large size Gear Shaft Coupling

When it comes to custom nonstandard casting for heavy machinery like dragline excavators, the 35# transmission large-size gear shaft coupling is a critical component. Here are five frequently asked questions to help you understand its importance and functionality:

1. **What is a 35# transmission large-size gear shaft coupling?**

The 35# transmission large-size gear shaft coupling is a custom-engineered component designed to connect the gear shaft to the transmission system in dragline excavators. Made from high-quality 35# steel, it ensures durability, strength, and precise alignment, which are essential for the heavy-duty operations of dragline excavators.

2. **Why is custom nonstandard casting necessary for this component?**

Dragline excavators operate under extreme conditions, requiring components that can withstand heavy loads, high torque, and constant wear. Custom nonstandard casting allows for the creation of parts tailored to specific machinery requirements, ensuring optimal performance, longevity, and compatibility with the excavator’s unique design.

3. **What are the key features of this gear shaft coupling?**

The 35# transmission large-size gear shaft coupling is known for its high tensile strength, resistance to wear and tear, and ability to handle high torque. Its precise engineering ensures smooth power transmission, reducing vibrations and minimizing the risk of mechanical failure. Additionally, it is designed to fit seamlessly into the dragline excavator’s transmission system.

4. **How does this component improve the performance of a dragline excavator?**

By providing a reliable connection between the gear shaft and transmission, this coupling enhances the excavator’s efficiency and operational stability. Its robust construction reduces downtime caused by component failure, ensuring uninterrupted performance in demanding mining and construction environments.

5. **What maintenance is required for the 35# transmission large-size gear shaft coupling?**

Regular inspection and lubrication are essential to maintain the coupling’s performance. Checking for signs of wear, misalignment, or damage during routine maintenance can prevent unexpected failures. Proper care ensures the coupling remains in optimal condition, extending the lifespan of both the component and the dragline excavator.

In summary, the 35# transmission large-size gear shaft coupling is a vital component for dragline excavators, offering durability, precision, and reliability. Its custom nonstandard casting ensures it meets the specific demands of heavy machinery, making it an indispensable part of your equipment.

(Dragline Excavator custom Nonstandard Casting 35#Transmission Large size Gear Shaft Coupling)

REQUEST A QUOTE

RELATED PRODUCTS

LinYao Dragline Excavator 1045 Transmission Steel Forging Spline large Helical Gear Shaft

Whole and retail Authentic sany excavator parts and PC oem parts for excavators sany spare parts

Doosan Daewoo DX215 220 225-5-7 Excavator Accessories New Hydraulic Rotary Motor Assembly Pump Valve Final Drive Used Swing

excavator spare parts Of excavator Chain Chain Rail Supporting Wheel Drive Tooth Guide Wheel Supporting Wheel Tensioning Device

Dragline Excavator Custom main drive Large Module Spur Gear Shaft Forged Transmission Spline Gear Shaft