PRODUCT PARAMETERS

Description

Brief introduction of High Quality Self-Grinding Ball Mill Machinery Iron Ore Mining Gear & Bearing Components Factory Direct from

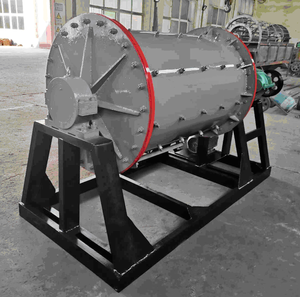

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. High Quality Self-Grinding Ball Mill Machinery Iron Ore Mining Gear & Bearing Components Factory Direct from refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of High Quality Self-Grinding Ball Mill Machinery Iron Ore Mining Gear & Bearing Components Factory Direct from

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(High Quality Self-Grinding Ball Mill Machinery Iron Ore Mining Gear & Bearing Components Factory Direct from)

Specification of High Quality Self-Grinding Ball Mill Machinery Iron Ore Mining Gear & Bearing Components Factory Direct from

The High Quality Self-Grinding Ball Mill Machinery for Iron Ore Mining is engineered to deliver exceptional performance, durability, and efficiency in demanding mining operations. Designed for grinding and processing iron ore, this machinery is built with precision and reliability in mind, ensuring optimal productivity and minimal downtime. The self-grinding feature eliminates the need for additional grinding media, reducing operational costs and maintenance requirements. The robust construction of the mill ensures it can withstand the harsh conditions of mining environments, providing long-lasting service. Key components such as gears and bearings are manufactured to the highest standards, ensuring smooth operation and reduced wear and tear. The gears are crafted from high-strength alloy steel, heat-treated for enhanced durability and resistance to heavy loads. The bearings are precision-engineered to support the mill’s rotational forces, ensuring stability and efficiency. Factory-direct sourcing guarantees that all components are of premium quality, with rigorous quality control measures in place to meet industry standards. The machinery is designed for easy installation and maintenance, with user-friendly features that simplify operation. Its energy-efficient design helps reduce power consumption, making it an environmentally friendly choice for mining operations. Whether used in large-scale mining projects or smaller operations, this self-grinding ball mill machinery is a reliable and cost-effective solution for processing iron ore. With its advanced technology, superior components, and factory-direct quality, it stands as a top choice for mining professionals seeking high-performance equipment.

(High Quality Self-Grinding Ball Mill Machinery Iron Ore Mining Gear & Bearing Components Factory Direct from)

Applications of High Quality Self-Grinding Ball Mill Machinery Iron Ore Mining Gear & Bearing Components Factory Direct from

High-quality self-grinding ball mill machinery is a game-changer in the iron ore mining industry, offering unparalleled efficiency, durability, and performance. Designed to handle the rigorous demands of ore processing, this advanced machinery is equipped with precision-engineered gear and bearing components, ensuring smooth operation and minimal downtime. The self-grinding mechanism eliminates the need for additional grinding media, reducing operational costs and enhancing productivity. Its robust construction and factory-direct sourcing guarantee reliability, making it an ideal choice for mining operations seeking to optimize their processes.

The gear and bearing components are crafted with high-grade materials and cutting-edge technology, ensuring exceptional wear resistance and longevity. These components are critical for maintaining the seamless rotation and stability of the ball mill, even under heavy loads and harsh conditions. By sourcing directly from the factory, customers benefit from cost-effective solutions without compromising on quality. The machinery is designed to deliver consistent grinding performance, enabling efficient extraction of iron ore and maximizing output.

Applications of this high-quality self-grinding ball mill machinery extend beyond iron ore mining. It is also suitable for processing other minerals, such as copper, gold, and nickel, making it a versatile investment for mining companies. Its energy-efficient design reduces power consumption, aligning with sustainable mining practices. Additionally, the machinery’s low maintenance requirements and easy-to-replace components further enhance its appeal, ensuring long-term operational efficiency.

In summary, this self-grinding ball mill machinery, with its superior gear and bearing components, is a reliable and cost-effective solution for iron ore mining and other mineral processing applications. Factory-direct sourcing ensures top-tier quality and affordability, making it an indispensable asset for mining operations aiming to achieve optimal performance and profitability.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High Quality Self-Grinding Ball Mill Machinery Iron Ore Mining Gear & Bearing Components Factory Direct from

1. What is a self-grinding ball mill, and how does it work?

A self-grinding ball mill is a type of grinding machine used in mining operations to reduce the size of iron ore and other materials. It operates by using the ore itself as the grinding medium, eliminating the need for steel balls. The ore is fed into the mill, where it is crushed and ground by the tumbling action of the ore particles. This process ensures efficient grinding and reduces energy consumption compared to traditional ball mills.

2. What makes your high-quality self-grinding ball mill machinery stand out?

Our self-grinding ball mill machinery is designed with precision engineering and durable materials to ensure long-lasting performance. It features advanced gear and bearing components that are factory-direct, ensuring reliability and minimal maintenance. The machinery is optimized for iron ore mining, offering high grinding efficiency, low operational costs, and consistent output quality.

3. Are your gear and bearing components factory-direct?

Yes, all gear and bearing components used in our self-grinding ball mill machinery are factory-direct. This means they are manufactured and supplied directly from our production facility, ensuring top-notch quality, competitive pricing, and timely delivery. Our components are rigorously tested to meet industry standards and withstand the demanding conditions of iron ore mining.

4. How does your machinery improve efficiency in iron ore mining?

Our self-grinding ball mill machinery is designed to maximize efficiency by reducing energy consumption and minimizing downtime. The self-grinding mechanism eliminates the need for additional grinding media, lowering operational costs. Additionally, the robust gear and bearing components ensure smooth operation and reduce the risk of mechanical failures, leading to higher productivity and consistent performance.

5. What kind of maintenance does your self-grinding ball mill machinery require?

Our machinery is built for durability and requires minimal maintenance. Regular inspections of the gear and bearing components, lubrication, and monitoring of operational parameters are recommended to ensure optimal performance. The factory-direct components are designed for easy replacement, reducing downtime and maintenance costs. With proper care, our self-grinding ball mill machinery delivers reliable performance over its lifespan.

(High Quality Self-Grinding Ball Mill Machinery Iron Ore Mining Gear & Bearing Components Factory Direct from)

REQUEST A QUOTE

RELATED PRODUCTS

Mining energy ball mill metal matric ceramic parts ceramic table liner grinding roller

Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding

Low Cost Factory Directly Spare Parts of Grinding Ball Mill Provided AC Motor Viet Nam Ball Milling Machine Energy & Mining

High manganese casting ball mill parts mill liner with good quality

Ball mill spare parts Ball mill ring gear and gears Ball mill Gears