PRODUCT PARAMETERS

Description

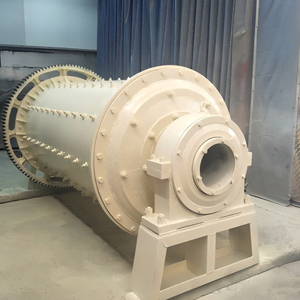

Brief introduction of Heavy Classifier Specification Machine Equipments Quartz Horizontal Customize Mining Grinding Ball Mill

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Heavy Classifier Specification Machine Equipments Quartz Horizontal Customize Mining Grinding Ball Mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Heavy Classifier Specification Machine Equipments Quartz Horizontal Customize Mining Grinding Ball Mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Heavy Classifier Specification Machine Equipments Quartz Horizontal Customize Mining Grinding Ball Mill)

Specification of Heavy Classifier Specification Machine Equipments Quartz Horizontal Customize Mining Grinding Ball Mill

The Heavy Classifier Spec Device Equipments Quartz Horizontal Customize Mining Grinding Round Mill is a durable, high-performance solution made for reliable grinding and category of quartz and other difficult minerals in mining procedures. Engineered for toughness and precision, this straight round mill incorporates advanced grinding innovation with a heavy-duty classifier to make certain optimal particle dimension distribution and processing efficiency. Its customizable layout allows adaptation to certain mining needs, including capability, power, and product handling.

Built from premium-grade steel and wear-resistant alloys, the mill includes strengthened liners to stand up to abrasive products and prolonged operation. The horizontal arrangement makes sure also worldly distribution and secure grinding efficiency. The incorporated classifier operates at flexible rates, allowing specific control over bit size result, typically ranging from 50 to 250 microns. Modification alternatives include drum dimensions (typical sizes: 2m to 5m in size, 4m to 15m in length), electric motor power (200 kW to 2500 kW), and ability (5 to 150 bunches per hour). The mill sustains grinding media such as steel or ceramic spheres, with sizes from 25mm to 100mm, customized to material solidity and fineness needs.

Key technical specs include a rotational speed of 10– 30 rpm, running temperature resistance up to 150 ° C, and compatibility with high-pressure settings. The classifier system boasts over 90% effectiveness, decreasing power intake and taking full advantage of outcome top quality. Safety features consist of overload protection, temperature level sensing units, and resonance tracking. Conformity with ISO 9001 and CE criteria makes certain reliability and operational safety.

Perfect for massive mining and mineral processing, this sphere mill masters quartz grinding but likewise handles granite, feldspar, and ores. Its energy-efficient style minimizes power intake by approximately 20% compared to traditional mills. Extra features consist of automated control systems for real-time changes, remote tracking capabilities, and easy-access upkeep factors. Built for continuous procedure in severe problems, it offers reduced downtime, extended solution intervals, and compatibility with global spare parts networks. This device is a functional, sturdy option for achieving accurate grinding and category in demanding mining applications.

(Heavy Classifier Specification Machine Equipments Quartz Horizontal Customize Mining Grinding Ball Mill)

Applications of Heavy Classifier Specification Machine Equipments Quartz Horizontal Customize Mining Grinding Ball Mill

The Heavy Classifier Specification Device Equipments Quartz Horizontal Customize Mining Grinding Round Mill is a robust, high-performance commercial maker crafted for precision grinding and classification sought after mining and mineral processing operations. Its sophisticated design integrates a straight round mill with a heavy-duty classifier system, allowing reliable bit size control and optimal material handling. Mostly used in quartz handling, this tools is likewise versatile to grind and identify a variety of ores, minerals, and commercial materials, making it indispensable in fields like mining, construction, ceramics, and chemical manufacturing.

In quartz mining and handling, the equipment excels at reducing quartz ore right into fine powders with consistent particle sizes, vital for applications in glass manufacturing, semiconductor manufacturing, and crafted rock items. The hefty classifier makes certain exact separation of ground fragments, boosting item top quality and lessening waste. For customized operations, the straight sphere mill can be customized to details throughput requirements, material solidity, and grinding excellence, supported by adjustable turning rates, liner setups, and classifier setups.

The devices’s straight style maximizes grinding performance by leveraging gravitational and centrifugal forces to maximize product circulation and grinding media activity. Its durable building, featuring wear-resistant alloys and strengthened elements, makes sure toughness in abrasive settings, reducing upkeep downtime. The integration of automated control systems permits real-time tracking of grinding parameters, guaranteeing regular result and power efficiency.

Past quartz, this ball mill is extensively used in handling sedimentary rock, feldspar, copper ore, and gold ore, accommodating markets needing ultra-fine powders or regulated bit distributions. Its adaptability reaches seal manufacturing, where it grinds clinker, and in metallurgy for grating steel ores. Customizable options include variable drum capacities, motor power configurations, and classifier requirements to meet varied functional demands.

By incorporating grinding and category in a single system, this machine enhances production process, reduces operational costs, and improves resource utilization. Its integrity, scalability, and precision make it a cornerstone of modern-day mineral handling, supplying high yields and remarkable item high quality throughout global mining and industrial markets.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Heavy Classifier Specification Machine Equipments Quartz Horizontal Customize Mining Grinding Ball Mill

What is the primary application of the Heavy Classifier Specification Quartz Horizontal Customized Mining Grinding Ball Mill? This machine is designed for grinding and classifying hard materials like quartz in mining, construction, and ceramics industries. Its horizontal design ensures stable, efficient processing, while the heavy classifier separates fine particles for consistent output. It’s ideal for high-precision tasks requiring uniform particle size distribution, such as mineral processing or industrial material preparation.

How does customization enhance performance? Customization allows tailoring the ball mill’s size, classifier specifications, and automation features to specific operational needs. Users can adjust grinding chamber dimensions, motor power, and classifier speed to optimize material throughput and fineness. Additional options include corrosion-resistant liners for abrasive materials or integration with IoT systems for real-time monitoring, ensuring adaptability to diverse mining or industrial environments.

What materials can this ball mill process besides quartz? While optimized for quartz, it handles materials like feldspar, silica sand, iron ore, copper ore, and ceramics. The heavy classifier and adjustable grinding mechanisms accommodate varying hardness and abrasiveness. Custom liners and grinding media (e.g., steel, ceramic balls) expand compatibility with corrosive or heat-sensitive materials, making it versatile for mineral processing, cement production, and chemical industries.

What maintenance is required for long-term reliability? Routine checks include inspecting liners and grinding balls for wear, lubricating bearings, and monitoring classifier blades. The robust horizontal design minimizes vibration-related stress, reducing mechanical failures. Automated systems alert users to potential issues like overheating or blockages. Manufacturers typically provide detailed maintenance schedules and remote support to ensure uptime and prolong equipment lifespan.

How does this machine ensure energy efficiency and safety? It uses high-efficiency motors and optimized grinding mechanics to reduce power consumption. The classifier prevents over-grinding, saving energy by recycling coarse particles. Safety features include emergency stop systems, overload protection, and sealed enclosures to contain dust and noise. Compliance with international mining safety standards ensures operator protection, while heat-resistant materials and fail-safe mechanisms mitigate operational risks.

(Heavy Classifier Specification Machine Equipments Quartz Horizontal Customize Mining Grinding Ball Mill)

REQUEST A QUOTE

RELATED PRODUCTS

Customized Heavy Duty Cnc Lathe Machining Casting Ball Mill Spare Parts Ball Mill End Cover

Customized Heavy Duty Cnc Lathe Machining Casting Cement Cap Ball Mill Heads Steel End Cover

High Chrome manganese Alloy cement quartz copper and gold ore ball mill liner wear plate spare parts

OEM Mining Machinery Parts Ball Mill Roller Shaft Cement Rotary Kiln Support Wheel Roller Shaft

Rolling Ring Tyre/big Riding Ring/ball Mill Ring Tyre Dryer Rotary Kiln Industrial Sprocket Transmission Gear Spare Parts