PRODUCT PARAMETERS

Description

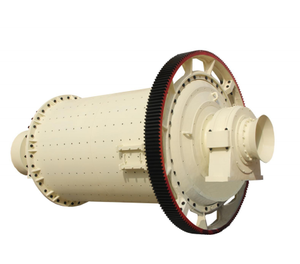

Brief introduction of Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone )

Specification of Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone

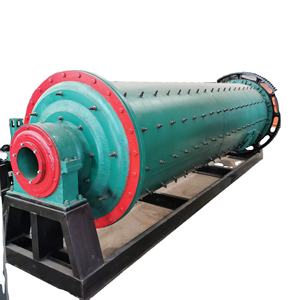

The Tiny 5t/h Sphere Mill is a functional grinding device created for handling gold ore, cement clinker, and sedimentary rock. Engineered for effectiveness and longevity, this portable sphere mill delivers dependable efficiency sought after mining and industrial applications. Its durable building and construction makes sure lasting procedure with minimal maintenance, making it optimal for small to medium-scale operations.

** Key Specs: **.

– ** Capacity: ** Processes approximately 5 lots of product per hour, flexible based upon material solidity and wanted excellence.

– ** Motor Power: ** Geared up with a 37 kW electric motor, giving regular torque for stable grinding operations.

– ** Turning Speed: ** Runs at 20– 25 rpm, maximized for effective product reduction and power efficiency.

– ** Drum Dimensions: ** Features a 1.5-meter size and 3-meter-long rotating drum, constructed from state-of-the-art manganese steel for wear resistance. Changeable liners (rubber or ceramic alternatives) safeguard the drum interior.

– ** Grinding Media: ** Utilizes steel balls (20– 100 mm in diameter) with a filling capability of 5– 10 tons, adjustable for product kind.

– ** Fragment Size: ** Accepts feed product approximately 25 mm and produces outcome fineness of 0.074 mm (200 mesh) or finer.

– ** Drive System: ** Gear-and-pinion transmission with a durable transmission, making sure smooth operation.

– ** Bearings: ** Big trunnion bearings sustain heavy loads and lower rubbing.

– ** Safety and security Characteristics: ** Consists of overload security, emergency situation stops, and safety guards for operator protection.

– ** Mobility: ** Compact layout with optional skid or wheel mounting for simple relocation.

** Applications: **.

– ** Gold Mining: ** Effectively grinds gold-bearing ores for additional extraction.

– ** Concrete Clinker: ** Processes clinker into fine concrete powder, immune to high-temperature materials.

– ** Sedimentary rock: ** Produces great sedimentary rock powder for construction, agriculture, or commercial usages.

** Advantages: **.

– ** Sturdiness: ** Top notch materials expand service life in unpleasant environments.

– ** Energy Effectiveness: ** Optimized layout lowers power consumption.

– ** Versatility: ** Deals with diverse products with flexible speed and grinding media.

– ** Reduced Upkeep: ** Easy accessibility for lining substitute and regular checks.

– ** Safety-Compliant: ** Fulfills commercial security standards for safe and secure procedure.

This round mill incorporates compactness, reliability, and precision, making it a cost-efficient solution for grinding applications in mining, cement production, and mineral handling.

(Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone )

Applications of Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone

The small 5t/h ball mill is a functional and effective grinding machine made for applications in gold mining, cement clinker processing, and limestone grinding. Its portable size and robust building and construction make it perfect for tiny to medium-scale operations, providing dependable efficiency across varied sectors.

** Gold Mining: ** In gold ore handling, the 5t/h sphere mill is made use of to grind crushed ore into great bits, enabling efficient gold removal through chemical leaching or physical splitting up techniques. Its capability to deal with rough materials makes sure regular grinding of hard rock ores, taking full advantage of area for greater recovery rates. The mill’s long lasting linings and grinding media withstand extreme mining problems, lowering downtime and upkeep costs.

** Cement Clinker Grinding: ** For cement manufacturing, this round mill grinds cement clinker into a great powder, which is blended with gypsum to produce top quality concrete. The 5t/h capacity fits tiny cement plants or jobs requiring specialized blends. Exact control over grinding criteria ensures consistent fragment size circulation, crucial for attaining optimum cement strength and setup buildings. Its energy-efficient design additionally lowers operational costs in clinker handling.

** Sedimentary rock Grinding: ** The mill processes limestone right into fine powder for applications in farming (dirt conditioning), construction (basic material for concrete), and environmental sectors (flue gas desulfurization). Its flexible grinding fineness enables customization to fulfill details industry standards, while its closed-circuit system decreases dust and waste.

** Trick Benefits: ** The 5t/h ball mill includes a portable impact, making it easy to mount in constrained areas. Its reduced power consumption and high grinding performance minimize operational expenditures. The mill’s modular layout simplifies upkeep, and wear-resistant components expand service life. It supports both completely dry and damp grinding modes, adjusting to varying material dampness degrees.

Ideal for remote or resource-limited settings, this round mill combines convenience, longevity, and cost-effectiveness. Whether grinding gold ore, concrete clinker, or sedimentary rock, it supplies regular performance, making certain efficiency and quality across industrial applications. A practical option for companies seeking reliable small grinding without jeopardizing on performance.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone

1. **What are the primary applications of the Small 5t/h Ball Mill?**

This ball mill is designed for versatile grinding tasks, including processing gold ore in mining operations, pulverizing cement clinker for hydraulic cement production, and grinding limestone to achieve fine powders for industrial uses like construction materials. It handles materials with varying hardness and moisture levels efficiently.

2. **What materials and design features ensure durability?**

The mill’s drum and liners are constructed from high-quality, wear-resistant steel or alloy to withstand abrasive materials. It uses hardened steel grinding balls for consistent performance. Robust welding, reinforced bearings, and a stable base minimize vibrations, extending the machine’s lifespan even under heavy-duty cycles.

3. **How energy-efficient is this ball mill?**

Optimized rotational speed and a streamlined design reduce power consumption. Advanced drive systems, such as gearboxes or belt drives, lower friction and energy waste. Its compact size ensures effective heat and energy distribution during grinding, making it cost-effective for small to medium-scale operations.

4. **What maintenance practices are recommended?**

Regular lubrication of bearings and gears every 500 hours is critical. Inspect liners and grinding balls monthly for wear and replace them when thickness drops below 10-15%. Check alignment and belt tension periodically. Immediate shutdown for unusual noises or vibrations prevents major breakdowns.

5. **Can the output fineness be adjusted?**

Yes. Adjust grinding duration, ball size (smaller balls for finer output), and rotation speed. Classifiers or screens can also refine particle size. For ultra-fine results, operate the mill in closed circuit with external separators. Trial runs help calibrate settings for specific materials like gold ore or limestone.

(Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone )

REQUEST A QUOTE

RELATED PRODUCTS

OEM customize cast alloy ball mill liners wear resistant lining plate spare parts

Wear resistant non-standard Heavy Machinery Ball Mill Parts large Casting Liner Plate

Factory Spare Parts For Mining Crusher Precision Ball Mill Liner Impact Crusher Hammer Crusher For Stone Crushing

Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500

Rotary kiln and cement ball mill spare pasts wheel and ring gear casting girth gear large steel spur gear