PRODUCT PARAMETERS

Description

Brief introduction of Steel Gold Ore Rock Mining Ball Mill Machine

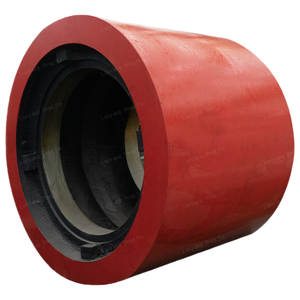

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Steel Gold Ore Rock Mining Ball Mill Machine refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Steel Gold Ore Rock Mining Ball Mill Machine

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Steel Gold Ore Rock Mining Ball Mill Machine)

Specification of Steel Gold Ore Rock Mining Ball Mill Machine

The Steel Gold Ore Rock Mining Round Mill Maker is a durable and efficient grinding devices developed for handling hard products such as gold ore, rocks, and other metal or non-metallic minerals in mining operations. Built for resilience and high efficiency, this equipment is engineered to manage both dry and wet grinding processes, making it versatile for different stages of mineral extraction and beneficiation.

** Key Specifications: **.

– ** Capacity: ** Available in versions with drum capabilities ranging from 0.5 to 150 cubic meters, accommodating small-scale artisanal mining to big commercial procedures. Throughput varies based upon ore solidity and feed size, commonly refining 1– 100 heaps per hour.

– ** Building: ** Produced from high-grade steel with enhanced linings to stand up to abrasive products and sturdy usage. The drum is lined with replaceable manganese steel or rubber linings for extended life expectancy and decreased upkeep.

– ** Power: ** Driven by electric motors with power ratings from 15 kW to 4500 kW, depending upon version size. Optional diesel engines are offered for remote operations without grid access.

– ** Turning Rate: ** Runs at 18– 38 RPM, enhanced for reliable grinding by balancing centrifugal pressure and material cascading. Rate can be adapted to achieve wanted excellence.

– ** Grinding Media: ** Uses solidified steel rounds (25– 150 mm diameter) or rods to squash and grind ore. Media dimension and composition are personalized based on material hardness and target particle size.

– ** Feed Dimension: ** Accepts raw ore as much as 25 mm in size, decreasing it to great powder as tiny as 75 microns (200 mesh) in closed-circuit systems.

– ** Dimensions: ** Differs by design, with drum diameters from 0.9 meters to over 4.5 meters and sizes approximately 8 meters for massive devices.

– ** Operational Functions: ** Consists of gearbox lubrication systems, temperature level sensors, and overload security. Easy-access design for maintenance, such as boltless liners and examination hatches.

– ** Safety Compliance: ** Satisfies ISO 9001 requirements and mining safety policies, with emergency stop devices and protective guards.

** Applications: ** Mostly utilized in gold, copper, and iron ore processing, this round mill is additionally suitable for cement, silicate items, and chemical industries. Its adaptability to various ores and grinding conditions makes certain constant result top quality.

** Devices: ** Optional attributes include automated control systems, dust collectors, and classifiers for improved efficiency. Adjustable setups for certain website needs.

** Ecological Factors To Consider: ** Developed for energy performance with enhanced electric motor systems to minimize power consumption. Sealed frameworks decrease dust exhausts during operation.

Perfect for extracting operations prioritizing integrity and precision, the Steel Gold Ore Rock Mining Ball Mill Maker incorporates sturdy building with innovative design to maximize efficiency in challenging settings.

(Steel Gold Ore Rock Mining Ball Mill Machine)

Applications of Steel Gold Ore Rock Mining Ball Mill Machine

The Steel Gold Ore Rock Mining Ball Mill Machine is an important piece of equipment in the mining and mineral handling markets, designed to grind and blend materials for efficient removal of beneficial metals. Its robust steel construction ensures resilience in severe mining settings, while its flexible design sustains applications across gold ore handling, steel manufacturing, and general rock mining operations.

In gold ore processing, the round mill plays a critical duty in the comminution circuit. After initial squashing, the ore is fed into the turning drum, where steel rounds effect and grind the material into a fine slurry. This grinding activity frees gold particles from the bordering rock, making it possible for effective splitting up via cyanidation, flotation protection, or gravity approaches. The device’s adjustable criteria, such as ball size and rotational speed, permit drivers to enhance fragment dimension for optimum gold recuperation.

For steel production, the ball mill is important in processing iron ore, a key raw material. Iron ore must be ground to a consistent excellence before beneficiation, pelletizing, or sintering– actions important for feeding blast furnaces. The device’s capacity to handle high volumes of rough ore guarantees a consistent supply of processed product, directly sustaining steel production efficiency.

In rock mining, the ball mill’s adaptability radiates. It refines a large range of ores, including copper, zinc, and lead, adjusting to varying firmness degrees and dampness material. Whether running in wet or completely dry problems, the equipment delivers consistent fragment size circulation, critical for downstream processes like smelting or leaching. Its durable design reduces downtime, also under constant operation, decreasing upkeep expenses for mining operations.

Key benefits consist of energy-efficient efficiency, customizable grinding settings, and the ability to deal with both small and industrial-scale workloads. By ensuring detailed ore breakdown, the round mill enhances the efficiency of succeeding removal approaches, making it crucial for making the most of resource yield. Mining companies and mineral handling plants depend on this equipment to accomplish functional effectiveness, cost-effectiveness, and consistent outcome sought after atmospheres.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Steel Gold Ore Rock Mining Ball Mill Machine

**What is a steel gold ore rock mining ball mill machine?**

A steel gold ore rock mining ball mill machine is industrial equipment used to grind or blend raw materials, such as gold-bearing rocks, ores, or other minerals, into fine particles. It uses rotating cylinders filled with steel balls to crush and grind materials via impact and friction, enabling efficient extraction of precious metals like gold.

**What factors determine the ball mill’s grinding capacity?**

Grinding capacity depends on the mill’s drum size, rotational speed, material hardness, feed size, and the quantity and size of steel grinding balls. Larger drums and optimal speed enhance productivity, while harder ores or improper feed size may reduce efficiency. Custom configurations are available to match specific mining requirements.

**How often does the ball mill require maintenance?**

Routine maintenance includes weekly checks of lubrication systems, bolts, and liners. Grinding balls and wear-prone components like liners should be replaced every 3–6 months, depending on usage intensity. Regular inspections prevent unexpected downtime and ensure consistent performance in harsh mining environments.

**Is the ball mill energy-efficient?**

Modern ball mills prioritize energy efficiency through features like variable-frequency drives, optimized gear design, and low-friction bearings. Energy consumption varies with load and material hardness, but advanced models minimize waste by balancing power use with grinding effectiveness, reducing operational costs over time.

**What safety precautions are necessary during operation?**

Operators must wear protective gear (helmets, gloves, ear protection) and ensure the mill is securely grounded. Avoid overloading the drum, and never perform maintenance while the machine is running. Regular training on emergency protocols and equipment handling is critical to prevent accidents in high-risk mining settings.

(Steel Gold Ore Rock Mining Ball Mill Machine)

REQUEST A QUOTE

RELATED PRODUCTS

Mill Machine Spare Part Ball Mill Pinion Shaft Mining Mineral Equipment Parts

High Chrome Manganese Alloy Cement and Mining Ball Mill Grinding Media Shell Liner Plate Wear Parts

Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500

Factory of Small Ball Mill 900×1800 For 1 Ton Gold Mine Ball Mill Parts

Small Ball Mill Grinding Machine with New Motor Core Component Ball Mill Spare Parts