PRODUCT PARAMETERS

Description

Brief introduction of Customizable OEM Ball Mill Motor

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Customizable OEM Ball Mill Motor refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Customizable OEM Ball Mill Motor

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

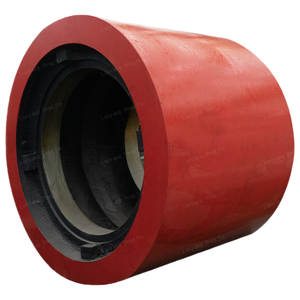

(Customizable OEM Ball Mill Motor)

Specification of Customizable OEM Ball Mill Motor

The Customizable OEM Round Mill Electric motor is engineered for precision, durability, and versatility to fulfill varied industrial grinding and milling demands. Made for smooth combination right into ball mill systems, this electric motor uses tailored solutions for original equipment suppliers (OEMs) seeking high-performance components enhanced for details functional needs.

** Power & Efficiency: ** The motor is available in a power range of 5 kW to 500 kW, supporting voltage arrangements from 220V to 660V (50/60 Hz) to align with global electrical standards. It supplies regular torque result, with a high starting torque of up to 150% of the ranked torque, guaranteeing smooth start-up under hefty lots. Variable rate control (using optional VFD compatibility) allows RPM modifications between 500 and 3000, satisfying material-specific grinding effectiveness.

** Building & Toughness: ** Constructed with durable actors iron or aluminum alloy housing, the motor is immune to mechanical stress and deterioration. Premium-grade insulation (Course F or H) makes sure thermal security in high-temperature settings, while IP55 or IP56 protection guards against dirt and dampness ingress. High-efficiency bearings (SKF/NSK) lower rubbing, expanding operational life approximately 20,000 hours under continual use.

** Energy Efficiency: ** Certified with IE3/IE4 effectiveness standards, the electric motor lessens power usage by as much as 15% compared to standard designs, reducing functional prices.

** Customization Options: ** OEMs can specify shaft measurements (keyed or keyless), placing types (foot, flange, or face), and cooling methods (TEFC or IC416). Added features include explosion-proof qualification (ATEX/Ex d), ingrained thermal sensors, and anti-vibration places. Custom-made branding, color pattern, and terminal box positioning are additionally readily available.

** Control & Assimilation: ** Suitable with PLCs and automation systems, the motor supports real-time monitoring of parameters like temperature level, vibration, and load by means of optional IoT-enabled sensors.

** Applications: ** Suitable for mining, concrete manufacturing, ceramics, and chemical processing, this electric motor makes certain reliable efficiency in grinding ores, minerals, and resources.

** Service warranty & Assistance: ** Backed by a 2-year service warranty, the item includes 24/7 technological assistance and international spare parts accessibility.

Developed for scalability and long life, the Adjustable OEM Ball Mill Motor incorporates advanced engineering with flexible style to boost efficiency across commercial applications.

(Customizable OEM Ball Mill Motor)

Applications of Customizable OEM Ball Mill Motor

Adjustable OEM round mill motors are engineered to satisfy the varied demands of sectors that rely upon grinding, blending, and homogenizing materials. These electric motors are customized to certain operational demands, supplying versatility in power, rate, torque, and design to optimize performance across applications. Right here are essential industries and make use of cases where these motors stand out:

** Mining and Metallurgy: ** Ball mills are critical for grinding ores and minerals into great powders for handling. Personalized electric motors adapt to varying load problems, making certain constant performance in removing precious metals like gold, copper, or iron. Flexible torque and rate settings improve power performance, reducing operational prices in high-demand settings.

** Ceramics and Cement Production: ** Accuracy grinding of basic materials like clay, silica, and sedimentary rock is necessary for high quality ceramics and cement. Motors with variable speed control make it possible for fine-tuning of fragment dimension circulation, improving product uniformity. Robust designs hold up against abrasive materials and high-temperature conditions typical in kiln feed prep work.

** Chemical and Drug Production: ** Ball mills procedure chemicals, pigments, and active pharmaceutical components (APIs) to accomplish micron-level fineness. Customized electric motors comply with sanitary standards (e.g., FDA, GMP) and deal explosion-proof choices for managing unstable materials. Silent procedure and compact layouts match lab-scale and manufacturing facilities.

** Renewable Resource Materials: ** In lithium-ion battery production, ball mills grind cathode/anode materials like lithium cobalt oxide or graphite. High-precision motors guarantee uniform bit dimension, straight affecting battery efficiency and life-span. Corrosion-resistant coverings safeguard motors from responsive chemicals throughout milling.

** Farming and Paints: ** Custom-made motors drive the production of fertilizers and pesticides by grinding raw minerals into soluble powders. In paint manufacturing, they disperse pigments uniformly for regular shade quality. Choices like dust-proofing and resonance damping expand motor long life in dirty or high-impact settings.

** Advantages of Modification: ** OEM round mill motors are built to integrate flawlessly with existing equipment, minimizing downtime during upgrades. Customers take advantage of energy-efficient designs that lower power consumption, long lasting components for extreme atmospheres, and scalable remedies for broadening operations. Personalized shafts, real estates, or cooling systems attend to space restraints or regulatory needs.

By lining up motor specifications with application-specific difficulties– such as tons irregularity, material abrasiveness, or ecological variables– customizable OEM sphere mill electric motors boost performance, lower maintenance costs, and assistance lasting manufacturing methods across sectors. Their versatility makes them a cornerstone of modern-day product handling process.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Customizable OEM Ball Mill Motor

What customization options are available for OEM ball mill motors? Customizable OEM ball mill motors can be tailored to meet specific power, speed, torque, and physical dimensions based on client requirements. Options include modifications to motor housing materials (cast iron, stainless steel), shaft designs, cooling systems (air or liquid), voltage/frequency compatibility, and integration with existing control systems. Branding elements like logos or color schemes can also be added.

What power range do these motors typically support? Customizable ball mill motors are available in a wide power range, typically from 10 kW to 1000 kW or higher, depending on application needs. The exact power capacity is determined by factors like material grindability, mill size, and operational load. Motors can be engineered for low-voltage (e.g., 380V) or high-voltage (e.g., 6.6 kV) systems to match regional or industrial standards.

How energy-efficient are these motors? OEM ball mill motors are designed with high-efficiency standards, often meeting IE3 or IE4 classifications. Advanced features like variable frequency drives (VFDs) optimize energy use by adjusting motor speed to match real-time grinding demands, reducing idle power consumption. Premium-grade copper windings and precision-engineered components further minimize energy loss.

Can the motor withstand harsh industrial environments? Yes. These motors are built with rugged materials and protective coatings to resist dust, moisture, and corrosive elements. Sealed bearings, reinforced insulation, and IP55/IP65 ingress protection ratings ensure reliable operation in high-temperature, high-vibration, or abrasive settings. Optional explosion-proof designs are available for hazardous environments.

What is the lead time for custom orders? Lead times vary based on design complexity and order volume, typically ranging from 4–8 weeks. Standard configurations may ship faster, while highly specialized units require additional engineering and testing. Suppliers often provide expedited options for urgent projects, though this may incur extra costs. Clear communication of specifications upfront helps streamline production.

(Customizable OEM Ball Mill Motor)

REQUEST A QUOTE

RELATED PRODUCTS

OEM customize cast alloy ball mill liners wear resistant lining plate spare parts

Gear Shaft For Ball Mill Spline Gear Shaft Mining Spare Parts Gear Shaft For Gearbox

Mining And Petroleum Machinery Forging Dryer Parts Ball Mill Non-standard Large Gear

Manufacture super good quality Resistant Mining Spare Parts ball mill rubber lining

Mining Equipment Parts Ball Mill Machine Mining Equipment Sand Making Machine Ball Grinding Mill Liner Spare Parts