PRODUCT PARAMETERS

Description

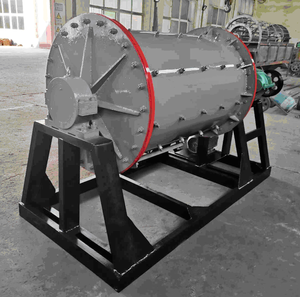

Brief introduction of Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover)

Specification of Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover

The Cement Plant Big Diameter ZG35 Sphere Mill Head and Ball Mill End Cover are important parts developed for sturdy grinding operations in concrete production and relevant sectors. Crafted from top quality ZG35 cast steel, these components use exceptional strength, use resistance, and toughness to endure high-impact tons and abrasive settings. The ZG35 material guarantees architectural stability under severe functional stress, decreasing the threat of splits or deformations over extended use.

The ball mill head and end cover are crafted for large-diameter round mills, normally varying from 2.5 to 5.5 meters in size, with wall densities maximized in between 100-250mm depending on mill dimension and functional requirements. Accuracy machining assurances smooth surface areas and precise dimensional tolerances, making certain smooth alignment with the mill shell and other components. The design integrates enhanced ribs and flanges to evenly distribute mechanical stress and anxiety, enhancing long life and lessening maintenance downtime.

Warmth therapy procedures, consisting of annealing and normalizing, are put on remove interior anxieties and enhance mechanical properties such as hardness and toughness. This ensures consistent efficiency in high-temperature grinding environments. Completion cover includes a bolted flange connection, suitable with common mill shells, and consists of pre-machined screw openings for secure assembly. Adjustable arrangements fit specific mill layouts, consisting of variations in inlet/outlet openings and lining attachment factors.

These parts are ideal for cement clinker grinding, resources processing, and mining applications, where dependability and efficiency are extremely important. Extensive quality assurance actions, including ultrasonic testing and X-ray inspection, guarantee defect-free production and conformity with global criteria like ASTM or ISO. By decreasing resonance and improving tons circulation, the ZG35 round mill head and finish cover contribute to smoother procedure, lower power consumption, and prolonged life span of the whole grinding system. Custom-made dimensions and specs are offered to meet diverse functional needs, making certain compatibility with both horizontal and upright ball mill setups.

(Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover)

Applications of Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover

The Applications of Cement Plant Huge Size ZG35 Ball Mill Head Round Mill End Cover

The Concrete Plant Huge Size ZG35 Ball Mill Head and Sphere Mill End Cover are crucial elements in commercial grinding systems, particularly designed for durable procedures in concrete production and associated industries. Engineered from ZG35 high-strength cast steel, these parts use phenomenal durability, put on resistance, and architectural honesty, making them optimal for supporting large-diameter sphere mills in extreme operating settings.

** Key Applications in Concrete Manufacturing **.

In cement plants, these mill heads and end covers are essential to raw material and clinker grinding procedures. The round mill head acts as an architectural support, protecting the mill’s turning cylinder and enduring the mechanical stress and anxieties generated during procedure. Completion cover guarantees a sealed, steady chamber for grinding resources like limestone, clay, and iron ore right into great powders, which are crucial for cement formula. During clinker grinding, the ZG35 parts withstand high-impact pressures and abrasive conditions, maintaining functional connection and preventing material leakage.

** Compatibility with Large-Scale Operations **.

Created for large-diameter sphere mills, these components sustain high-capacity assembly line, making it possible for effective processing of bulk materials. Their durable building decreases deformation under hefty lots, ensuring positioning with the mill’s trunnion and decreasing resonance. This compatibility enhances grinding effectiveness and expands the lifespan of the whole milling system.

** Flexibility Throughout Industries **.

Beyond concrete production, ZG35 ball mill heads and finish covers are made use of in mining, metallurgy, and chemical sectors for grinding ores, coal, and other minerals. Their flexibility to varied materials and operating conditions underscores their utility in any kind of high-tonnage grinding application.

** Secret Advantages **.

The ZG35 product’s exceptional mechanical residential or commercial properties minimize wear-related downtime, reducing maintenance costs. Accuracy engineering ensures airtight sealing, stopping worldly loss and contamination. Furthermore, their resistance to thermal anxiety and exhaustion supports 24/7 procedures, vital for conference manufacturing targets.

** Verdict **.

The Concrete Plant Huge Diameter ZG35 Round Mill Head and End Cover are crucial for industries reliant on robust grinding remedies. By incorporating high-performance products with precision layout, these components boost operational reliability, minimize lifecycle prices, and guarantee regular result in concrete production and beyond. Their duty in sustaining efficient, large-scale grinding procedures makes them a cornerstone of modern commercial milling.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover

1. **What material is the ZG35 Ball Mill Head/End Cover made of?**

The ZG35 Ball Mill Head and End Cover are manufactured using ZG35 cast steel, a high-quality carbon steel alloy known for its superior strength, wear resistance, and durability. This material ensures the components withstand heavy mechanical stress, high-temperature conditions, and abrasive environments typical in cement plant operations.

2. **Why is ZG35 preferred for large-diameter ball mills?**

Large-diameter ball mills require components that can handle extreme rotational forces and prolonged operational loads. ZG35 cast steel offers excellent mechanical properties, including high tensile strength and impact resistance, making it ideal for large mill heads and end covers. Its robustness minimizes deformation risks, ensuring stable performance and extended service life even under continuous grinding cycles.

3. **How is the Ball Mill End Cover installed?**

Installation involves aligning the end cover precisely with the mill shell and securing it using high-strength bolts. Proper alignment is critical to prevent vibration or misalignment during operation. Sealing gaskets or welding (depending on design) are applied to ensure airtightness, preventing material leakage. Professional technicians and heavy machinery are recommended for safe, efficient installation.

4. **Can the ZG35 End Cover be customized for specific mill sizes?**

Yes, the ZG35 End Cover can be customized in diameter, thickness, and bolt-hole patterns to match the specifications of different ball mills. Manufacturers often tailor designs to suit existing equipment, ensuring compatibility with mill shells, liners, and drive systems. Customization helps optimize performance and integration with plant infrastructure.

5. **What maintenance practices extend the lifespan of the Ball Mill Head/End Cover?**

Regular inspections for cracks, wear, or corrosion are essential. Check bolt tightness and sealing integrity every 6–12 months. Lubricate joints to reduce friction and monitor for abnormal vibrations. Immediate replacement of damaged components prevents secondary damage to the mill. Proper maintenance ensures operational efficiency and reduces unplanned downtime in cement production.

(Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover)

REQUEST A QUOTE

RELATED PRODUCTS

Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From

ball mill spare parts All Sizes Provided high manganese forged steel ball

Rotary Kiln and Cement Ball Mill Spare Pasts Large Steel Spur Gear Wheel and Ring Gear Casting Girth Gear

Ball mill Spare parts ball mill liner accessories ball mill liner plate

heavy duty mining ball mill spare part 42CrMo steel hollow shaft