PRODUCT PARAMETERS

Description

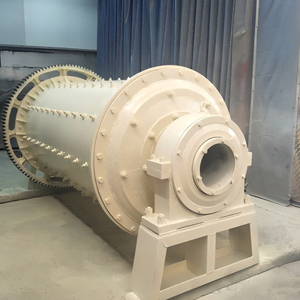

Brief introduction of Low Energy Saving ball mill grinding cement grinding ball mill

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Low Energy Saving ball mill grinding cement grinding ball mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Low Energy Saving ball mill grinding cement grinding ball mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Low Energy Saving ball mill grinding cement grinding ball mill)

Specification of Low Energy Saving ball mill grinding cement grinding ball mill

The Low Power Conserving Ball Mill for concrete grinding is a high-efficiency industrial grinding remedy created to lower power usage while preserving ideal performance in concrete manufacturing. Engineered with innovative modern technologies, this sphere mill decreases power use by as much as 30% compared to traditional mills, making it a green and cost-effective selection for modern-day concrete plants. Its robust building guarantees sturdiness and dependability, also under continual sturdy procedures. The mill features a high-efficiency motor with variable regularity drive (VFD) modern technology, making it possible for precise control over rotational speed and torque to match grinding needs. The optimized design includes a structured cyndrical tube structure and low-friction bearings, minimizing mechanical resistance and energy loss. It operates at a rotational speed of 15– 25 RPM, stabilizing grinding efficiency and energy financial savings. The mill supports a wide variety of abilities, generally refining 5– 200 tons of concrete clinker per hour, relying on design dimension. Power intake ranges from 18– 450 kW, tailored to manufacturing scale. The grinding chamber is lined with wear-resistant materials such as high-chromium steel or alumina porcelains, extending life span and decreasing maintenance prices. Feed particle dimension is adjustable as much as 25 mm, with output fineness controlled in between 300– 400 m ²/ kg Blaine to fulfill cement top quality criteria. An integrated automatic control system keeps track of criteria like temperature level, stress, and product circulation, ensuring regular item quality and operational safety. The mill’s small layout minimizes floor space needs, while its modular components simplify setup and maintenance. By utilizing innovative grinding media circulation and maximized grinding kinetics, it attains remarkable bit dimension circulation with minimal energy input. This round mill follows ISO and global energy performance requirements, adding to lower carbon emissions and functional prices. Appropriate for both new installments and retrofitting existing plants, it is optimal for grinding Rose city concrete, slag, and combined cements. Trick benefits consist of lowered power usage, lower thermal emissions, prolonged equipment life-span, and conformity with sustainability goals. Its mix of efficiency, effectiveness, and reliability makes it a favored selection for cement manufacturers intending to boost efficiency while decreasing environmental influence.

(Low Energy Saving ball mill grinding cement grinding ball mill)

Applications of Low Energy Saving ball mill grinding cement grinding ball mill

The reduced energy conserving ball mill is an advanced improvement in cement grinding technology, created to optimize effectiveness while significantly minimizing power usage. This high-performance tools is crafted to grind cement clinker, gypsum, and extra materials like slag or fly ash into great cement powder, a crucial step in concrete manufacturing. Its applications span across concrete plants seeking cost-effective, lasting services without jeopardizing outcome high quality. By incorporating sophisticated electric motor systems, enhanced grinding media, and cutting-edge lining designs, this round mill reduces friction and energy waste, attaining approximately 30% reduced energy usage contrasted to traditional mills. Automated control systems better boost performance by dynamically readjusting operational parameters such as turning rate and material circulation, ensuring ideal grinding problems and avoiding over-processing. The mill’s robust building and construction with wear-resistant materials ensures toughness, reducing upkeep downtime and extending life span. This integrity converts to constant production prices, crucial for meeting high-demand cement production timetables. Eco, the reduced power consumption straight decreases carbon discharges, assisting plants follow stringent ecological policies and sustainability goals. Financially, the reduced functional prices from lower energy and upkeep expenditures enhance revenue margins, making cement production more affordable. Furthermore, the mill’s convenience permits it to handle varying material hardness and wetness degrees, guaranteeing uniform bit size circulation for premium concrete high quality. Its flexibility to both new installments and retrofits in existing plants makes it a functional choice for innovation tasks. In summary, the reduced energy conserving round mill is a transformative service for the concrete industry, stabilizing efficiency, cost-efficiency, and ecological duty. By prioritizing power financial savings and operational reliability, it sustains lasting growth while maintaining high criteria in cement production.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Low Energy Saving ball mill grinding cement grinding ball mill

What is a Low Energy Saving Ball Mill for cement grinding? A Low Energy Saving Ball Mill is a specialized grinding machine designed to reduce energy consumption while maintaining high efficiency in cement production. It uses advanced technologies like optimized rotational speed, energy-efficient motors, and improved grinding media arrangement to minimize power usage. This type of ball mill ensures effective grinding of clinker, gypsum, and other raw materials into fine cement powder with up to 30% less energy compared to traditional mills.

Why choose a Low Energy Saving Ball Mill over conventional cement mills? This mill prioritizes sustainability and cost-effectiveness. It reduces operational expenses by cutting energy consumption and lowering carbon emissions. Its design minimizes heat generation and material waste, ensuring consistent particle size distribution. Additionally, it operates smoothly with less vibration and noise, extending equipment lifespan and reducing maintenance needs.

How does the Low Energy Saving Ball Mill achieve energy efficiency? Key features include a uniquely designed rotating cylinder with low-friction bearings, high-efficiency separators, and grinding media (steel balls) optimized for size and density. The mill’s drive system uses frequency converters to adjust speed based on material load, preventing energy waste. Advanced insulation retains heat during grinding, further reducing energy demands.

What maintenance does this ball mill require? Maintenance is minimal due to robust construction and wear-resistant materials like chromium alloy liners. Regular checks include lubrication of bearings, inspection of grinding media for wear, and monitoring motor performance. Its simplified design allows easy access to internal components, reducing downtime.

Can this mill handle materials other than cement clinker? Yes. While optimized for cement grinding, it can process minerals, ores, slag, and industrial by-products. Adjustable parameters like rotation speed, grinding media type, and feed size make it versatile for various industries, including mining and ceramics, while maintaining energy-saving benefits.

(Low Energy Saving ball mill grinding cement grinding ball mill)

REQUEST A QUOTE

RELATED PRODUCTS

Casting Girth Gears Rotary Kiln And Cement Ball Mill Spare Parts Large Steel Spur Gear Wheel and Ring Gear

Manufacture super good quality Resistant Mining Spare Parts ball mill rubber lining

Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone

High Chrome manganese Alloy cement quartz copper and gold ore ball mill liner wear plate spare parts

Iron Ore Ball Mills Gypsum Grinding Ball Mill Machine Gold Provided AC Motor Spare Part of Cement Factory Steel Ball Mill 1year