PRODUCT PARAMETERS

Description

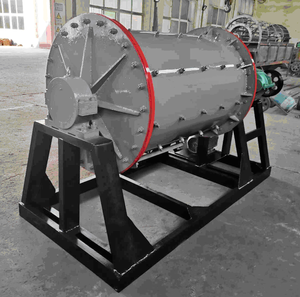

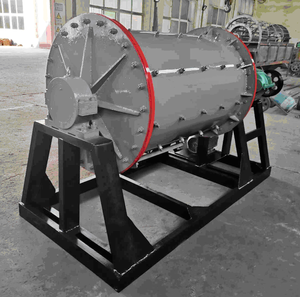

Brief introduction of Factory Direct Durable High Quality Casting Ore Ball Mill Motor For Ball Mill For

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Factory Direct Durable High Quality Casting Ore Ball Mill Motor For Ball Mill For refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Factory Direct Durable High Quality Casting Ore Ball Mill Motor For Ball Mill For

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Factory Direct Durable High Quality Casting Ore Ball Mill Motor For Ball Mill For )

Specification of Factory Direct Durable High Quality Casting Ore Ball Mill Motor For Ball Mill For

The Factory Straight Long Lasting Premium Quality Spreading Ore Ball Mill Electric motor is crafted to provide robust performance, reliability, and longevity sought after industrial settings. Developed specifically for powering sphere mills used in ore handling, concrete manufacturing, and mineral grinding, this motor incorporates innovative design with sturdy building and construction to guarantee smooth operation under high-load conditions.

** Core Specifications: **.

– ** Electric motor Kind: ** Three-phase asynchronous induction electric motor, maximized for constant obligation cycles.

– ** Power Rating: ** Available in a variety from 30 HP to 500 HP, customizable to fulfill certain torque and speed needs.

– ** Voltage: ** Compatible with 220V, 380V, 440V, or various other industrial voltage criteria, with optional voltage change.

– ** Performance Class: ** IE3 or IE4 (premium performance) to reduce power usage and functional expenses.

– ** Building: ** High-grade cast iron or steel housing for superior resilience, corrosion resistance, and warm dissipation.

– ** Protection Ranking: ** IP65/IP67 access protection, ensuring resistance to dust, dampness, and rough ecological problems.

– ** Cooling System: ** Entirely Encased Fan-Cooled (TEFC) layout for consistent thermal administration.

– ** Insulation Class: ** Course F or H insulation products, with the ability of standing up to high temperatures as much as 155 ° C( Class F )or 180 ° C( Course H).

– ** Bearings: ** Durable, oiled bearings (SKF/NSK/TIMKEN) for reduced rubbing, reduced maintenance, and expanded service life.

– ** Noise Degree: ** Runs below 75 dB for minimal acoustic effect in industrial settings.

– ** Installing: ** Foot-mounted or flange-mounted configurations to match varied mill configurations.

– ** Speed up Control: ** Fixed-speed or variable-frequency drive (VFD) compatibility for exact RPM adjustments.

– ** Certifications: ** Compliant with ISO 9001, CE, and IEC requirements for quality control and global applicability.

** Secret Benefits: **.

– ** Factory Straight Prices: ** Eliminates middlemen, offering affordable options without compromising quality.

– ** High Torque Output: ** Guarantees smooth start-up and constant power delivery for grinding hefty ore loads.

– ** Reduced Maintenance: ** Sealed building and construction and costs elements lower downtime and fixing expenses.

– ** Flexibility: ** Appropriate for damp or dry grinding procedures in mining, concrete, and metallurgical markets.

** Operational Variety: **.

– ** Ambient Temperature level: ** -20 ° C to +50 ° C.- ** Elevation: ** Approximately 1,000 meters above water level (derating options readily available for greater elevations).

** Warranty: ** Backed by a 12-24-month guarantee, with dedicated technological assistance for installation and troubleshooting. Perfect for sectors prioritizing performance, longevity, and overall cost of possession in ball mill operations.

(Factory Direct Durable High Quality Casting Ore Ball Mill Motor For Ball Mill For )

Applications of Factory Direct Durable High Quality Casting Ore Ball Mill Motor For Ball Mill For

The manufacturing facility straight durable high-quality spreading ore ball mill electric motor is crafted to supply exceptional performance sought after commercial environments, specifically in ore handling and mineral grinding applications. Built with precision-cast components and durable products, this electric motor is made to stand up to the extensive functional demands of round mills, making sure long life, reliability, and effectiveness in critical procedures.

** Main Applications: **.

1. ** Mining and Mineral Handling: ** This electric motor is perfect for driving sphere mills used in grinding ores such as gold, copper, iron, and other metal or non-metallic minerals. Its high torque and constant power output allow effective pulverization of basic materials right into great powders, a crucial step in mineral removal and beneficiation.

2. ** Concrete Manufacturing: ** In concrete plants, the electric motor powers sphere mills for grinding clinker, gypsum, and other additives to create cement. Its toughness guarantees uninterrupted procedure under high-load conditions, decreasing downtime in constant manufacturing cycles.

3. ** Chemical and Ceramic Industries: ** The electric motor sustains sphere mills made use of in grinding chemicals, pigments, and ceramic resources, where precision and harmony in particle dimension are crucial for product high quality.

** Trick Benefits: **.

– ** Longevity: ** Built with high-quality spreading and wear-resistant materials, the motor withstands rust, abrasion, and thermal anxiety, also in extreme atmospheres.

– ** Energy Efficiency: ** Optimized layout decreases power consumption, lowering functional expenses while preserving high grinding effectiveness.

– ** Steady Performance: ** Engineered for smooth operation with minimal vibration, the motor ensures regular mill efficiency, lowering endure mechanical components.

– ** Customization: ** Available in varying power rankings and setups to match specific sphere mill requirements, accommodating diverse industrial needs.

– ** Reduced Maintenance: ** Secured components and sophisticated cooling systems lessen maintenance needs, prolonging solution periods and lifecycle.

** Suitable for Heavy-Duty Usage: **.

This electric motor is fit for continuous 24/7 operations in markets where reliability is non-negotiable. Its factory-direct supply guarantees cost-effectiveness without jeopardizing quality, making it a favored selection for services prioritizing functional efficiency and long-term ROI.

By integrating this motor into your ball mill systems, you improve performance, reduce power waste, and guarantee consistent outcome quality, making it a foundation of contemporary ore processing and material grinding operations.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Factory Direct Durable High Quality Casting Ore Ball Mill Motor For Ball Mill For

**What materials are used in the construction of the Factory Direct Durable High Quality Casting Ore Ball Mill Motor?**

The motor is built with premium-grade cast iron and reinforced steel components, ensuring exceptional durability and resistance to wear. Critical parts like the rotor, stator, and housing undergo precision casting and heat treatment to enhance strength and longevity. High-quality copper windings and insulation materials guarantee efficient electrical performance, even under heavy loads.

**What power range does this ball mill motor support?**

This motor is designed for industrial-scale operations, offering a power range of 15 kW to 450 kW. It supports variable speed configurations to match different ore grinding requirements. The robust design ensures consistent torque delivery, making it suitable for continuous operation in harsh mining or cement production environments.

**How does this motor ensure energy efficiency?**

Advanced engineering minimizes energy loss through optimized magnetic circuits and reduced friction bearings. The motor operates at a high efficiency class (IE3 or higher), lowering electricity consumption while maintaining output. Its thermal management system prevents overheating, further enhancing performance and reducing operational costs over time.

**Is the motor compatible with all types of ball mills?**

Yes, the motor is engineered for universal compatibility with horizontal, vertical, and conical ball mills. It includes adjustable mounting brackets and standardized shaft dimensions to fit most mill setups. Customizable voltage and frequency options (e.g., 220V/380V, 50Hz/60Hz) ensure seamless integration with global power systems.

**What maintenance is required for this motor?**

Routine maintenance includes lubrication of bearings every 1,000 operating hours and periodic inspection of electrical connections for corrosion or wear. The sealed housing protects against dust and moisture, reducing internal debris buildup. Annual professional servicing is recommended to check alignment, insulation resistance, and rotor balance, ensuring optimal performance and lifespan exceeding 10 years under normal conditions.

(Factory Direct Durable High Quality Casting Ore Ball Mill Motor For Ball Mill For )

REQUEST A QUOTE

RELATED PRODUCTS

Large Casting Steel Parts ZG310-570 Ball Mill end Cover foundries Large Ball Mill Cover

Superir Hot Low Ball Mill Grinding Machine With Lower Starting Power

Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From

Spare Parts For Mining Crusher Precision Ball Mill Liner For Stone Crushing

Small ball mill grinding machine small ball mill grinding machine ball mill spare parts