PRODUCT PARAMETERS

Description

Brief introduction of Ball grinding mill , ball mill offer

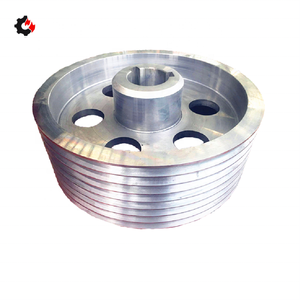

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Ball grinding mill , ball mill offer refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Ball grinding mill , ball mill offer

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Ball grinding mill , ball mill offer)

Specification of Ball grinding mill , ball mill offer

The Ball Grinding Mill is a durable and flexible device made for fine grinding and mixing of various materials, including ores, chemicals, porcelains, and paints. It operates the principle of effect and attrition, where turning drums filled with grinding media (usually steel or ceramic balls) reduce material particle size through repeated accidents. This tools is extensively used in mining, cement, construction, and metallurgy industries for its efficiency in attaining consistent bit distribution and high grinding accuracy.

Trick specifications consist of a cylindrical covering size varying from 0.6 to 4.5 meters and lengths as much as 6 meters, accommodating abilities from small laboratory sets (5-100 liters) to commercial production (as much as 100 tons per hour). The mill operates at 65-75% of vital rate, with electric motor power ranging 15 kW for portable units to 4500 kW for large-scale designs. Building and construction products include top quality steel, rubber, or ceramic liners to prevent contamination and boost toughness. Feed dimensions commonly range as much as 25 mm, with discharge fineness adjustable from 75 microns to as low as 10 microns using control of grinding time, ball dimension, and product circulation.

Grinding media choices consist of created steel, stainless-steel, or ceramic spheres, with diameters from 25 mm to 150 mm, selected based on material hardness and wanted fineness. The mill features a gear-driven or belt-driven system, with optional automated controls for rate, temperature level, and result monitoring. Safety devices include overload defense and emergency situation stops.

Our ball mill offer includes personalization to fulfill certain operational requirements, such as tailored dimensions, linings, and motor setups. We supply thorough technical assistance, installment advice, and operator training. All mills comply with global security and high quality standards (ISO, CE), backed by a 12-month service warranty and lifetime access to spare parts. Competitive pricing is available for bulk orders, with energy-efficient styles to lessen operational expenses. For improved performance, optional functions consist of dust extraction systems, cooling jackets, and programmable reasoning controllers (PLCs). Get in touch with us for a thorough quote tailored to your grinding needs.

(Ball grinding mill , ball mill offer)

Applications of Ball grinding mill , ball mill offer

A round grinding mill is a flexible and crucial piece of equipment used across multiple industries to grind, mix, and procedure products into fine powders or homogeneous combinations. Its cylindrical chamber, full of grinding media such as steel or ceramic balls, turns to produce impact and rubbing, effectively reducing particle dimension. Sphere mills are extensively embraced in mining, ceramics, chemicals, building, pharmaceuticals, and paints due to their versatility and accuracy. In the mining industry, sphere mills grate ores like gold, copper, and iron to remove useful steels with additional processing. The porcelains industry relies on them to mix basic materials such as silica and clay, guaranteeing harmony in items like ceramic tiles and porcelain. Chemical plants use sphere mills for grinding reactive substances and facilitating chain reactions, while the building market depends on them to create carefully ground cement and sedimentary rock. Drug firms utilize sphere mills to attain ultra-fine powders for medicines, guaranteeing uniformity and bioavailability. In paints and finishings, they distribute pigments uniformly for dynamic, resilient coatings. Round mills offer high efficiency in both damp and dry grinding, creating uniform bit dimensions critical for quality assurance. Their durable layout ensures sturdiness, even with rough materials, and personalized functions like variable speed and lining products boost performance. Reduced maintenance demands, energy-efficient operation, and scalability– from small lab versions to large commercial systems– make them affordable services. Safety and security features such as enclosed chambers and overload security prioritize individual health. With the capability to take care of diverse products and supply regular outcomes, sphere grinding mills continue to be indispensable for achieving precision and performance in industrial applications.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Ball grinding mill , ball mill offer

1. **What is a ball grinding mill, and how does it work?**

A ball grinding mill, or ball mill, is a cylindrical device used to grind materials into fine powder. It works by rotating a chamber filled with grinding media (typically steel or ceramic balls) and the material to be processed. As the mill rotates, the balls collide with the material, crushing and grinding it through impact and friction. This process ensures uniform particle size reduction, making it ideal for mining, cement, and chemical industries.

2. **What materials can a ball mill process?**

Ball mills are versatile and can grind a wide range of materials, including ores, ceramics, chemicals, and pigments. Common applications include grinding cement clinker, limestone, coal, and metallic ores. However, abrasive or extremely hard materials may require specialized liners or grinding media to prevent excessive wear. Wet or dry grinding options are available depending on material properties and end-use requirements.

3. **What factors affect the efficiency of a ball mill?**

Key factors include rotational speed, ball size and material, grinding time, and the feed size of the material. Optimal speed ensures the balls cascade effectively without sliding. Larger balls suit coarse grinding, while smaller ones refine particles. Overloading the mill or using worn-out media reduces efficiency. Proper maintenance of liners and consistent feed rates also impact performance.

4. **How do I maintain a ball mill for longevity?**

Regular lubrication of bearings and gears is critical. Inspect liners and grinding media for wear, replacing them as needed to prevent contamination or reduced efficiency. Clean the mill after processing corrosive materials, and ensure all components are tightened to avoid vibrations. Follow manufacturer guidelines for operational limits and shutdown procedures to prevent mechanical failures.

5. **How to choose the right ball mill for my needs?**

Consider material hardness, required fineness, and production capacity. Lab-scale mills suit small batches, while industrial mills handle high-volume processing. Decide between wet or dry grinding based on material compatibility and end-product specifications. Check power requirements, chamber size, and compatibility with auxiliary equipment like classifiers or feeders. Reputable suppliers offer customization for specific applications.

(Ball grinding mill , ball mill offer)

REQUEST A QUOTE

RELATED PRODUCTS

Effective Large Capacity Ball.Mill Ball Mill For Mining

Made in Customizable Rotary Kiln Spare Parts 42CrMo4 Segmented Rotary Kiln Girth Ball Mill Ring Gear For Cement Plant

Mineral Ball Mill Spare Parts Gold Grinder Ball Mills Machine Metal Ball Mill for Gold Mining

Customized Wear-resistant Plate Durable Ball Mill Liner For Mining

Energy and Mineral Equipment 2023 OEM Ball Mill Spare Parts Negotiable Guaranteed Quality High Chrome(Machining Available)