PRODUCT PARAMETERS

Description

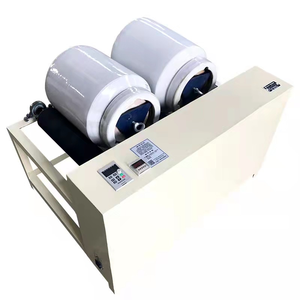

Brief introduction of Supply Ball Mill Stone Grinding Mill Ball Mill Grinding Machine For Rock Gold Engineering and building materials machinery

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Supply Ball Mill Stone Grinding Mill Ball Mill Grinding Machine For Rock Gold Engineering and building materials machinery refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Supply Ball Mill Stone Grinding Mill Ball Mill Grinding Machine For Rock Gold Engineering and building materials machinery

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Supply Ball Mill Stone Grinding Mill Ball Mill Grinding Machine For Rock Gold Engineering and building materials machinery)

Specification of Supply Ball Mill Stone Grinding Mill Ball Mill Grinding Machine For Rock Gold Engineering and building materials machinery

The Sphere Mill Stone Grinding Equipment is a sturdy commercial equipment created for grinding and refining tough products such as rocks, ores, and minerals, specifically in rock gold mining and building materials manufacturing. Engineered for sturdiness and effectiveness, this maker is ideal for reducing material particle size through constant turning, utilizing steel spheres as grinding media. Its durable building makes sure dependable efficiency in rough environments, making it ideal for extracting operations, concrete plants, metallurgy, and chemical markets.

Trick specifications consist of a variety of models with capacities from 0.5 to 150 bunches per hour, powered by electric motors covering 5.5 kW to 450 kW. The rotational rate ranges 18 to 36 RPM, maximized for efficient product grinding. The grinding chamber is lined with high-manganese steel or wear-resistant rubber to lengthen life span. It suits feed product measure to 25 mm, generating result fineness between 0.075 mm and 0.4 mm. The equipment operates via a horizontal cylindrical structure, driven by a girth gear and pinion assembly for smooth turning.

Attributes consist of an automatic lubrication system, overload security, and temperature monitoring to make sure operational security. The style emphasizes energy performance, reducing power usage by as much as 30% contrasted to traditional mills. Its modular building and construction permits easy maintenance, with quick-access panels for replacing liners or grinding media. Noise degrees are lessened with vibration-dampening places and soundproofing products.

Benefits include flexibility in managing completely dry and wet grinding procedures, adaptability to different ore kinds, and regular output quality. The device sustains constant 24/7 procedure with very little downtime, backed by a heavy-duty gearbox and strengthened bearings. Applications extend past gold ore processing to cement clinker grinding, silicate item production, and ceramic material manufacturing.

Customizable alternatives consist of variable speed drives, automated control systems, and bespoke chamber measurements. Conformity with worldwide standards like ISO and CE warranties high quality and safety. This round mill is an economical solution for large projects requiring high throughput and precision grinding, supplying long-term integrity and low operational expenses. Perfect for industrial users looking for an equilibrium between efficiency, durability, and maintenance efficiency.

(Supply Ball Mill Stone Grinding Mill Ball Mill Grinding Machine For Rock Gold Engineering and building materials machinery)

Applications of Supply Ball Mill Stone Grinding Mill Ball Mill Grinding Machine For Rock Gold Engineering and building materials machinery

The Applications of Supply Ball Mill Rock Grinding Mill Round Mill Grinding Maker for Rock Gold Engineering and Building Materials Equipment. Round mills are versatile grinding devices extensively utilized in markets such as mining, building and construction, and materials processing. Their robust design and effective operation make them optimal for lowering hard, abrasive materials right into fine powders. In Rock Gold Engineering, sphere mills play a vital duty in handling gold-bearing ores. They grind smashed ore into ultrafine particles, promoting effective gold removal through chemical procedures like cyanidation or physical approaches such as gravity separation. The equipment’s capacity to manage high-capacity grinding makes sure consistent throughput in gold handling plants, also in remote or tough atmospheres. Its resilience and low maintenance requirements make it a cost-effective solution for mineral processing procedures. In building materials equipment, round mills are necessary for producing cement, ceramics, and various other construction-related products. They grind raw materials like sedimentary rock, clay, and gypsum right into fine powders, which are after that blended and heated to create concrete clinker. The specific control over fragment size makes certain top notch concrete with ideal strength and setup homes. For ceramic production, ball mills grind silica, feldspar, and various other additives to accomplish consistent uniformity, vital for forming and firing processes. The maker’s adaptability permits it to process varied materials, consisting of commercial minerals and recycled structure products, sustaining sustainable production techniques. The round mill’s style features a turning drum loaded with grinding media, such as steel spheres, which collide with the material to squash and grind it. Advanced designs provide adjustable speed and lining configurations to enhance efficiency for particular applications. With minimal power consumption and high grinding effectiveness, these makers lower operational prices while preserving efficiency. Developed to stand up to sturdy use, the ball mill grinding machine is a trustworthy possession for sectors needing accuracy, scalability, and long-lasting performance in product handling. Its applications encompass chemical, pharmaceutical, and metallurgical sectors, underscoring its convenience as a foundation of industrial grinding innovation.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Supply Ball Mill Stone Grinding Mill Ball Mill Grinding Machine For Rock Gold Engineering and building materials machinery

What is a ball mill grinding machine, and how does it work? A ball mill is a cylindrical device used to grind materials like rocks, ores, and cement into fine powder. It operates by rotating a chamber filled with grinding media (steel or ceramic balls). As the cylinder rotates, the balls cascade and collide with the material, crushing and grinding it through impact and friction. The ground product is discharged through a screen, with fineness adjusted by controlling rotation speed, grinding time, and ball size.

What materials can a ball mill process for rock gold and building materials? This machine is designed for hard, abrasive materials such as gold-bearing quartz, granite, limestone, cement clinker, and ceramics. It handles dry or wet grinding, though moisture content must be monitored to avoid clogging. For gold processing, it efficiently pulverizes ore to extract precious metals, while in construction, it grinds raw materials for cement, tiles, or refractory products.

What maintenance does a ball mill require? Regular lubrication of bearings and gears is critical to minimize wear. Inspect liners and grinding balls periodically for erosion or damage, replacing them as needed. Clean the mill to prevent material buildup, and check alignment and motor function. Proper maintenance reduces downtime and extends the machine’s lifespan.

What advantages does a ball mill offer over other grinding mills? Ball mills excel in producing ultra-fine, consistent particle sizes, ideal for gold recovery and precise material blends. They handle high-capacity workloads, operate continuously, and are durable for heavy industrial use. Unlike vertical or hammer mills, they’re versatile for both wet and dry processes and adapt to varying material hardness.

Is a ball mill cost-effective for industrial use? Yes. Its robust design ensures long-term operation with minimal breakdowns, lowering repair costs. High grinding efficiency reduces energy consumption, and the ability to process diverse materials eliminates the need for multiple machines. Over time, its reliability and low operational costs make it a strong investment for mining and construction sectors.

(Supply Ball Mill Stone Grinding Mill Ball Mill Grinding Machine For Rock Gold Engineering and building materials machinery)

REQUEST A QUOTE

RELATED PRODUCTS

Hot Mining Machinery Parts High Manganese Steel Balls Forged Grinding Ball Media for Ball Mill

High Quality Factory Supply Mining Cement limestone powder rotary dry wet gold copper ore Grinding Ball Mill

Lab Ball Mill Machine Mill Stone Gold Ore Ball Mill Liner Wear Plate Spare Parts

Gear Shaft For Ball Mill Spline Gear Shaft Mining Spare Parts Gear Shaft For Gearbox

Ball mill spare parts Ball mill liners Ball mill liner