PRODUCT PARAMETERS

Description

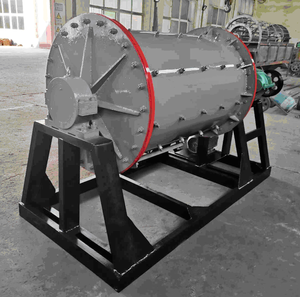

Brief introduction of High quality ball mill mining rod mill sand making ball mill for grinding powder

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. High quality ball mill mining rod mill sand making ball mill for grinding powder refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of High quality ball mill mining rod mill sand making ball mill for grinding powder

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(High quality ball mill mining rod mill sand making ball mill for grinding powder)

Specification of High quality ball mill mining rod mill sand making ball mill for grinding powder

High-grade round mills, consisting of mining pole mills and sand-making ball mills, are crafted for accuracy grinding throughout industries such as mining, construction, and powder handling. These robust equipments transform raw materials like ores, quartz, silica sand, and minerals right into great powders or consistent granules, guaranteeing ideal performance and longevity.

** Specs: **.

** Construction: ** Constructed with durable steel or alloy shells, strengthened with abrasion-resistant liners (manganese steel, rubber, or ceramic) to stand up to harsh grinding atmospheres. The cylindrical design guarantees constant rotation and material processing.

** Capability & Capacities: ** Available in several dimensions, with drum sizes ranging from 0.5 to 4.5 meters and lengths approximately 8 meters. Throughput varies from 0.5 TPH (small) to 150 TPH (commercial), dealing with diverse production requirements.

** Motor & Power: ** Geared up with high-torque electrical motors (5.5 kW to 4500 kW) for trusted performance. Variable-speed drives enable control over rotation (10– 35 RPM for sphere mills; somewhat faster for pole mills), maximizing grinding fineness and energy use.

** Grinding Media: ** Compatible with steel poles (pole mills for crude grinding) or hardened steel/ceramic spheres (round mills for fine powder). Media sizes range from 25 mm to 150 mm, tailored to output requirements.

** Material Handling: ** Processes feed measure to 50 mm, creating results as great as 45 microns. Suitable for cement, silicates, porcelains, and ore beneficiation.

** Key Functions: **.

– ** Durability: ** Corrosion-resistant components and heat-treated gears make sure longevity.

– ** Accuracy: ** Adjustable discharge grates control fragment size distribution.

– ** Power Effectiveness: ** Advanced drive systems reduce power consumption by as much as 30%.

– ** Safety: ** Overload security, emergency stops, and sealed rooms reduce operational threats.

– ** Automation: ** Optional IoT-enabled sensing units monitor lots, temperature level, and output in actual time.

** Upkeep: ** Developed for easy accessibility to linings and grinding media, with low downtime for substitutes. Grease-lubricated bearings and modular parts simplify maintenance.

** Conformity: ** Meets ISO 9001, CE, and global mining safety criteria. Optional dirt collection agencies and noise-reduction systems (85 dB max) address environmental guidelines.

** Applications: ** Squashing coal, grinding limestone for cement, creating silica sand for glass, or refining steel ores. Personalized with cooling systems, classifiers, or vibratory feeders.

This sphere mill integrates tough dependability with advanced technology, delivering regular grinding performance while decreasing functional prices and environmental influence. Suitable for companies focusing on top quality, scalability, and lasting ROI in mineral handling and commercial powder production.

(High quality ball mill mining rod mill sand making ball mill for grinding powder)

Applications of High quality ball mill mining rod mill sand making ball mill for grinding powder

Top notch ball mills, pole mills, and sand-making round mills are flexible commercial makers created for grinding and refining basic materials into fine powders or consistent granules. These durable grinding systems are essential in markets such as mining, building and construction, metallurgy, concrete, and chemical handling, where accuracy, effectiveness, and durability are critical.

In mining operations, ball mills and rod mills are essential for pulverizing ores like gold, copper, iron, and rare planet minerals. The rod mill, with its grinding media of steel poles, masters crude grinding, breaking down big ore fragments into smaller, manageable sizes before more refinement in sphere mills. Ball mills, geared up with steel spheres, after that finely grind the material into a consistent powder, allowing effective mineral extraction through procedures like flotation protection or leaching. Their ability to take care of unpleasant and hard materials makes them suitable for continual mining operations.

Sand-making round mills are engineered for generating premium man-made sand and accumulations by grinding basic materials such as limestone, granite, or quartz. This is essential in construction, where regular particle shapes and size improve the toughness and workability of concrete and asphalt. These mills guarantee ideal gradation and minimize gaps in mixed products, boosting the resilience of framework jobs.

In the chemical and ceramic markets, ball mills grind pigments, fertilizers, and ceramic precursors into ultra-fine powders, ensuring homogeneity and reactivity. The regulated grinding environment protects against contamination and allows for flexible excellence, meeting stringent industry standards.

Trick advantages of these mills consist of high power efficiency, low maintenance because of durable linings and elements, and versatility to wet or dry grinding modes. Advanced creates feature automated control systems for exact procedure, lowering human mistake and functional expenses.

Ecologically, modern-day mills prioritize reduced energy usage and dust reductions, aligning with sustainable techniques. Adjustable arrangements– such as variable speed drives, liner products, and discharge devices– allow tailored solutions for details material kinds and production goals.

Whether processing steel ores, making building and construction products, or creating commercial powders, high-grade round mills, pole mills, and sand-making sphere mills deliver dependability, scalability, and consistent efficiency, making them foundational tools in international industrial and infrastructural growth.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High quality ball mill mining rod mill sand making ball mill for grinding powder

(High quality ball mill mining rod mill sand making ball mill for grinding powder)

REQUEST A QUOTE

RELATED PRODUCTS

High manganese casting ball mill parts mill liner with good quality

Factory Direct Supply High Quality ball mill with rubber liner ball mill

Ball mill spare parts Ball mill liners Ball mill liner

Mineral Ball Mill Spare Parts Gold Grinder Ball Mills Machine Metal Ball Mill for Gold Mining

OEM customize cast alloy ball mill liners wear resistant lining plate spare parts