PRODUCT PARAMETERS

Description

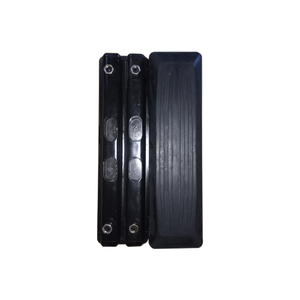

Introduction to towed Track Roller Lower Rollers Bottom Roller for Excavator Undercarriage Parts SK20 SK30

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Track Roller Lower Rollers Bottom Roller for Excavator Undercarriage Parts SK20 SK30 refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Track Roller Lower Rollers Bottom Roller for Excavator Undercarriage Parts SK20 SK30

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Track Roller Lower Rollers Bottom Roller for Excavator Undercarriage Parts SK20 SK30)

Specification of Track Roller Lower Rollers Bottom Roller for Excavator Undercarriage Parts SK20 SK30

The Track Roller Lower Rollers Base Roller for Excavator Undercarriage Parts SK20 SK30 is a critical component created to make sure smooth operation, stability, and long life of excavator undercarriages. These rollers are engineered to withstand hefty loads, abrasive surface, and rough working problems, making them excellent for construction, mining, and earthmoving applications.

** Material & Construction: ** Produced from state-of-the-art alloy steel, these rollers undergo accuracy warm treatment (quenching and tempering) to enhance surface solidity (HRC 55-60) and core durability, ensuring resistance to put on, effect, and deformation. The rollers include a secured, lubed design with premium bearings to stop dust, particles, and wetness ingress, decreasing rubbing and maintenance demands.

** Compatibility: ** Particularly created for SK20 and SK30 excavator designs, these rollers are interchangeable with OEM requirements, making sure smooth combination with existing undercarriage systems. Personalized sizing options may be available for other designs.

** Dimensions: ** Requirement external diameters vary between 120mm to 150mm, with bore diameters of 40mm to 50mm, depending on the version. Width varies from 60mm to 80mm, optimized for well balanced weight circulation and load capability. Each roller considers roughly 5-8 kg, balancing longevity and operational efficiency.

** Tons Capacity: ** Rated for vibrant loads up to 12,000 N and static tons exceeding 25,000 N, these rollers sustain sturdy applications without jeopardizing efficiency.

** Toughness Attributes: ** The outer surface is solidified and ground to resist abrasion, while inner seals retain oil and block contaminants. Anti-corrosion layers or phosphate therapies secure against rust in wet or destructive atmospheres.

** Maintenance: ** Pre-lubricated and sealed permanently, these rollers call for minimal upkeep. Regular evaluation for wear and seal stability is recommended.

** Applications: ** Ideal for rough, sloppy, or uneven terrains, these rollers make sure smooth track activity, reducing undercarriage tension and driver exhaustion.

** Quality control: ** Produced under ISO 9001 requirements, each roller goes through strenuous screening for dimensional accuracy, lots tolerance, and durability.

** Service warranty: ** Backed by a 12-month service warranty, covering problems in product or workmanship.

This item assures enhanced excavator efficiency, lowered downtime, and cost-efficient replacement for SK20/SK30 undercarriages.

(Track Roller Lower Rollers Bottom Roller for Excavator Undercarriage Parts SK20 SK30)

Applications of Track Roller Lower Rollers Bottom Roller for Excavator Undercarriage Parts SK20 SK30

Track roller lower rollers, additionally referred to as lower rollers, are critical elements in the undercarriage system of excavators such as the SK20 and SK30 models. These rollers play a vital role in distributing the equipment’s weight, guiding the track chain, and guaranteeing smooth procedure across varied surfaces. Made to withstand hefty tons, abrasion, and rough working conditions, they are essential for preserving the security, mobility, and durability of the excavator.

** Applications of Track Roller Lower Rollers for SK20/SK30 Excavators: **.

1. ** Tons Distribution: ** Bottom rollers bear the excavator’s weight and move it equally to the tracks, reducing ground stress. This is important for preventing dirt compaction and minimizing sinkage on soft or uneven surface areas, such as building websites or agricultural fields.

2. ** Track Placement: ** They keep the track chain lined up during operation, protecting against derailment and irregular wear. Proper alignment ensures regular contact between the track and ground, improving traction and decreasing slippage throughout excavating or lifting jobs.

3. ** Terrain Versatility: ** SK20 and SK30 excavators typically operate in difficult environments like rough landscapes, sloppy websites, or debris-filled locations. Premium lower rollers soak up shocks and vibrations, enabling smooth activity while securing the undercarriage from influence damages.

4. ** Durability in Severe Problems: ** Built from solidified steel or alloy materials, these rollers resist wear from abrasive bits, dampness, and corrosion. This longevity is vital for expanding the undercarriage’s service life in mining, forestry, or demolition applications.

5. ** Decreased Upkeep Prices: ** Precision-engineered rollers reduce rubbing in between the track links and undercarriage elements, lowering warmth generation and wear. This lowers downtime for fixings and substitutes, boosting operational effectiveness.

** Model-Specific Advantages: **.

The SK20 and SK30 excavators need rollers customized to their small dimension and load capacity. OEM-compatible bottom rollers ensure seamless combination, optimal efficiency, and adherence to maker specs. Their durable layout supports high-speed traveling and durable cycles, making them optimal for tiny to medium excavation jobs, landscaping, and utility work.

By picking premium-grade track roller lower rollers for SK20/SK30 excavators, drivers improve maker integrity, minimize lasting expenses, and keep peak efficiency sought after applications. Regular evaluation and timely substitute of worn rollers are recommended to protect undercarriage integrity and protect against functional interruptions.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Track Roller Lower Rollers Bottom Roller for Excavator Undercarriage Parts SK20 SK30

What are Track Roller Lower Rollers (Bottom Rollers) for SK20/SK30 excavators? Track Roller Lower Rollers, also called Bottom Rollers, are critical components in an excavator’s undercarriage. They support the machine’s weight, guide the track chain, and ensure smooth movement over rough terrain. For SK20 and SK30 models, these rollers are engineered to handle moderate to heavy workloads while maintaining stability and reducing wear on adjacent parts.

Are SK20/SK30 Track Roller Lower Rollers compatible with other excavator models? No. These rollers are specifically designed for the SK20 and SK30 excavators to ensure precise fitment and performance. Using rollers meant for other models can lead to improper alignment, accelerated wear, or damage to the undercarriage. Always verify compatibility using the excavator’s model number or consult the manufacturer before purchasing.

What materials are used in SK20/SK30 Bottom Rollers? These rollers are constructed from high-grade alloy steel, hardened through heat treatment for superior strength and durability. The sealed, lubricated bearings and hardened outer surfaces resist abrasion, corrosion, and impact, ensuring longevity even in harsh conditions like mud, rocks, or extreme temperatures.

How do I know when to replace Track Roller Lower Rollers? Signs of wear include uneven track tension, excessive noise during operation, visible cracks or flat spots on the rollers, or reduced excavator mobility. Regular inspections are key—check for leaks, play in the bearings, or irregular wear patterns. Timely replacement prevents costly damage to the track chain, sprockets, or idlers.

What is the average lifespan of SK20/SK30 Bottom Rollers? Lifespan varies based on operating conditions, but with proper maintenance, they typically last 1,500–2,000 hours. Frequent use in abrasive environments (e.g., rocky terrain) may shorten this interval. Always follow the manufacturer’s maintenance schedule, clean debris regularly, and lubricate components to maximize roller life and undercarriage efficiency.

(Track Roller Lower Rollers Bottom Roller for Excavator Undercarriage Parts SK20 SK30)

REQUEST A QUOTE

RELATED PRODUCTS

Hot ing excavator parts Undercarriage 400-135 400YM-135 450-154 Rubber Track Pad

excavator Hydraulic Shear Demolition Attachments Rotating Shear

Construction Machinery Parts Bulldozer Excavator Undercarriage Parts Track Roller Track Chain Link Idler Carrier Roller For

machining heavy duty dragline excavator spare parts hot long spur large module gear rack

Excavator Hydraulic Breaker Ear Plates Head Top Brackets