PRODUCT PARAMETERS

Description

Brief introduction of OEM Lime Plant Custom Large Diameter Ring Gear Ball Mill Forging Support Roller Shaft Rotary Kiln Parts

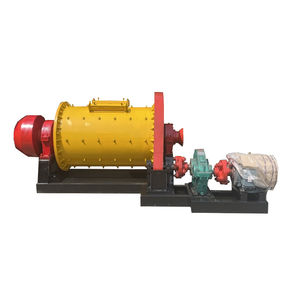

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. OEM Lime Plant Custom Large Diameter Ring Gear Ball Mill Forging Support Roller Shaft Rotary Kiln Parts refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of OEM Lime Plant Custom Large Diameter Ring Gear Ball Mill Forging Support Roller Shaft Rotary Kiln Parts

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(OEM Lime Plant Custom Large Diameter Ring Gear Ball Mill Forging Support Roller Shaft Rotary Kiln Parts)

Specification of OEM Lime Plant Custom Large Diameter Ring Gear Ball Mill Forging Support Roller Shaft Rotary Kiln Parts

OEM Lime Plant Personalized Huge Diameter Ring Equipment, Ball Mill Forging, Assistance Roller Shaft, and Rotary Kiln Components are precision-engineered elements developed for sturdy industrial applications in lime processing, cement production, and mineral grinding. These components are produced to meet strict high quality criteria, ensuring durability, dependability, and optimal efficiency under extreme operating problems.

** Huge Size Ring Gear **: Customizable for rotating kilns and sphere mills, these equipments are crafted from high-grade alloy steel, ensuring high wear resistance and load-bearing capacity. Diameters vary from 1.5 meters to 10 meters, with components customized to client specifications. Accuracy machining assurances smooth meshing with pinions, lessening vibration and sound. Warmth therapy procedures like carburizing or induction hardening improve surface firmness (up to 55-60 HRC) while preserving core toughness.

** Round Mill Forging **: Essential for grinding procedures, forged parts such as trunnions, girth equipments, and liners are generated making use of high-carbon steel or chromium-molybdenum alloys. Built under high stress, these components display exceptional structural integrity, high influence resistance, and prolonged life span. Personalized dimensions suit mill dimensions from 1.8 m to 6m in diameter.

** Support Roller Shaft **: Engineered to withstand heavy tons from rotating kilns and dryers, these shafts are produced from high-strength steel (ASTM 4340/4140). Accuracy machining ensures limited resistances ( ± 0.01 mm), while surface area treatments like nitriding or thermal spraying enhance wear resistance. Tons abilities range from 50 to 500 loads, with diameters up to 1.2 meters.

** Rotating Kiln Components **: Adjustable elements like kiln tires, rollers, and thrust rollers are made for high-temperature settings (up to 1500 ° C). Materials include heat-resistant alloys (e.g., ZG40Cr25Ni20) with superb thermal stability. Advanced spreading and creating methods make sure dimensional precision and resistance to thermal tiredness.

All components undertake strenuous top quality checks, including ultrasonic testing, magnetic fragment evaluation, and dimensional verification. Personalization alternatives include material grades, heat therapy methods, and surface coatings. Applications extend concrete plants, lime production, and mining industries, supplying enhanced functional efficiency, minimized downtime, and extended equipment life-span. Conformity with ISO 9001 and CE criteria assurances integrity. For specific demands, OEM solutions supply tailored services to match special operational needs.

(OEM Lime Plant Custom Large Diameter Ring Gear Ball Mill Forging Support Roller Shaft Rotary Kiln Parts)

Applications of OEM Lime Plant Custom Large Diameter Ring Gear Ball Mill Forging Support Roller Shaft Rotary Kiln Parts

OEM lime plant custom big diameter ring gears, ball mill forgings, support roller shafts, and rotating kiln parts are important components in hefty commercial equipment, developed to guarantee functional effectiveness, resilience, and integrity in demanding atmospheres. These parts are widely made use of in industries such as cement production, lime processing, mining, metallurgy, and chemical production, where high-performance equipment is crucial for continual procedures.

** Huge Diameter Ring Gears ** are integral to rotating kilns and round mills, giving exact rotational movement to promote product handling. Custom-engineered for lime plants, these gears are constructed to handle extreme torque and tons stress and anxieties, guaranteeing smooth transmission in between the kiln or mill and its drive system. Their robust building reduces wear, prolongs service life, and decreases upkeep downtime.

** Ball Mill Forgings **, consisting of trunnions, equipments, and linings, are crucial for grinding resources into fine powders. Built from high-strength alloys, these components endure recurring impacts and abrasion, preserving architectural honesty even under hefty lots. Personalization makes sure compatibility with certain mill measurements and operational needs, enhancing grinding effectiveness and energy intake.

** Assistance Roller Shafts ** are vital for stabilizing rotating kilns and clothes dryers, bearing the weight of the rotating drum while ensuring positioning. Precision-machined from long lasting products, these shafts stand up to deformation and thermal anxiety, enabling constant efficiency in high-temperature environments. Their dependability prevents kiln imbalance, decreasing the threat of expensive functional disturbances.

** Rotary Kiln Components **, such as tires, rollers, and girth equipments, are engineered to endure extreme heat, mechanical stress, and chemical direct exposure. These elements ensure smooth turning and warmth circulation during calcination, clinker manufacturing, or material drying. Customized remedies tailored to kiln specifications enhance thermal efficiency and lengthen tools lifespan.

OEM proficiency in manufacturing these elements warranties adherence to stringent top quality criteria, including material traceability, heat treatment precision, and dimensional precision. Modification choices accommodate distinct plant formats, functional parameters, and material features, guaranteeing seamless integration with existing systems. By picking OEM-certified parts, industries gain from enhanced performance, lowered operational costs, and minimized downtime, making these elements important for contemporary industrial procedures.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of OEM Lime Plant Custom Large Diameter Ring Gear Ball Mill Forging Support Roller Shaft Rotary Kiln Parts

1. What customization options are available for OEM lime plant ring gears and rotary kiln parts? Customization includes material selection (e.g., high-grade alloy steel, carbon steel), dimensional adjustments (diameter, thickness, bore size), heat treatment specifications (quenching, tempering), and surface finishing (machining, grinding). Engineering support is provided to align designs with specific operational requirements, such as load capacity or environmental conditions. 2. How is the durability of large-diameter ring gears ensured? Durability is achieved through advanced forging techniques that enhance grain structure, coupled with precision machining for optimal gear tooth geometry. Materials undergo rigorous testing (ultrasonic, hardness, chemical analysis) to meet ISO standards. Heat treatment processes like carburizing or induction hardening are applied to improve wear resistance and fatigue strength, ensuring long-term performance under heavy loads. 3. What maintenance do support roller shafts require? Regular lubrication and alignment checks are critical to prevent uneven wear. Inspect for surface cracks or deformation every 3–6 months, depending on usage. Use high-temperature grease compatible with rotary kiln operations. Replace seals periodically to avoid contamination. Proper alignment reduces stress on shafts, extending service life. 4. Can you accommodate urgent lead times for custom ball mill forgings? Yes, expedited production is available for urgent orders. Standard lead times range from 4–8 weeks, but this can be reduced by 30–50% through prioritized scheduling and overtime manufacturing. Clients must share detailed specifications upfront to avoid delays. Real-time updates are provided throughout the process. 5. Do your rotary kiln parts comply with international safety standards? All components are manufactured according to ISO 9001 guidelines and undergo stringent quality control checks. Certifications like CE or ASME are provided upon request. Materials are traceable, with test reports covering chemical composition, mechanical properties, and non-destructive testing (NDT). Custom parts are designed to meet regional safety regulations for global shipments.

(OEM Lime Plant Custom Large Diameter Ring Gear Ball Mill Forging Support Roller Shaft Rotary Kiln Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Coal mill in thermal power plant centrifugal fan oil filter element spare parts ball mill coal mill to generate electricity

Factory Spare Parts For Mining Crusher Precision Ball Mill Liner Impact Crusher Hammer Crusher For Stone Crushing

Factory custom mining equipment ball mill drive parts accessories Hollow shaft

High Manganese Steel Alloy Chromium Wear Resistance Vertical Ball Mill Rubber Liner Plate Impact Crusher Wear Parts Liner

Ball Mill