PRODUCT PARAMETERS

Description

Introduction to towed original spare parts Excavator Spare Parts construction machinery spare parts for

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.original spare parts Excavator Spare Parts construction machinery spare parts for refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed original spare parts Excavator Spare Parts construction machinery spare parts for

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(original spare parts Excavator Spare Parts construction machinery spare parts for )

Specification of original spare parts Excavator Spare Parts construction machinery spare parts for

Initial spare components for excavators and building equipment are crafted to fulfill stringent top quality criteria, making sure ideal performance, toughness, and compatibility with your equipment. These elements are made using high-grade materials such as enhanced steel, alloy composites, and advanced polymers, created to endure severe operating problems, including heavy loads, abrasion, and temperature variants. Precision machining and stringent quality control procedures ensure precise dimensions and resistances, guaranteeing smooth integration with OEM machinery designs. Trick specifications include adherence to original devices supplier (OEM) plans, certifications such as ISO 9001, and compliance with sector security policies. Parts like hydraulic pumps, track chains, boom arms, and container teeth are examined for exhaustion resistance, rust security, and load-bearing capability to match the long life of factory-installed parts. Electrical and hydraulic systems, consisting of sensors, shutoffs, and pipes, are adjusted to preserve operational performance and avoid leakages or system failures. Real parts undertake strenuous screening for wear resistance, impact stamina, and thermal security, guaranteeing minimal downtime and lowered upkeep expenses. Packaging includes anti-corrosion therapies and OEM-branded labeling for authenticity. Each component is traceable using identification numbers, providing warranty protection and access to technological support. Compatibility spans significant excavator brand names and versions, with detailed specifications covering weight, dimensions, torque scores, pressure thresholds, and product composition. As an example, undercarriage parts like rollers and idlers feature solidified surfaces for extensive life span, while securing aspects utilize high-performance rubber compounds to stop contamination. Engine components, such as filters and pistons, meet discharge standards and fuel effectiveness demands. By utilizing initial extra components, drivers make certain machinery runs at peak productivity while maintaining resale value and safety conformity.

(original spare parts Excavator Spare Parts construction machinery spare parts for )

Applications of original spare parts Excavator Spare Parts construction machinery spare parts for

Original spare parts for excavators and building machinery are critical to maintaining the performance, security, and durability of hefty equipment sought after atmospheres. These parts are crafted to fulfill the specific specs of OEM (Initial Equipment Supplier) requirements, ensuring smooth integration and integrity. Below are vital applications of making use of real extra parts in construction and excavation operations:

** Undercarriage Elements: ** Track chains, rollers, idlers, and sprockets sustain severe tension throughout excavation. Initial undercarriage components are constructed with high-grade products to resist wear, reduce ground damages, and keep security on irregular surface. They prolong the life expectancy of the equipment while reducing downtime for replacements.

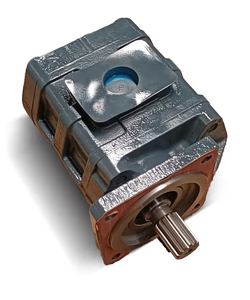

** Hydraulic Equipments: ** Excavators count on hydraulic pumps, cyndrical tubes, and shutoffs for accurate activity and power. Authentic hydraulic parts protect against leakages, pressure decreases, and system failures, making certain smooth operation of attachments like buckets, breakers, and grapples.

** Engine and Fuel Solutions: ** Initial filters, injectors, and turbochargers enhance fuel effectiveness and reduce exhausts. They secure engines from contamination and getting too hot, critical for sturdy cycles in construction websites.

** Accessories and Containers: ** Wear-resistant teeth, adapters, and reducing sides made from OEM-grade steel enhance digging effectiveness and minimize product spillage. These parts withstand abrasive soils and rocks, maintaining performance in mining or earthmoving projects.

** Electric and Control Systems: ** Sensing units, electrical wiring harnesses, and control components make sure accurate procedure of contemporary excavators. Original electric elements avoid malfunctions in GPS-guided systems, alarms, and diagnostics tools, sustaining compliance with safety and security methods.

** Wear Parts Replacement: ** Bushings, seals, and bearings should be replaced occasionally. Real components reduce friction, stop rust, and preserve placement in relocating parts, lowering the threat of devastating malfunctions.

Using original extra components safeguards equipment investments by protecting resale worth and preventing expensive repair services from inappropriate aftermarket alternatives. They likewise ensure conformity with producer guarantees and governing requirements. Contractors and fleet managers benefit from predictable maintenance timetables, reduced complete ownership expenses, and nonstop project timelines.

In recap, OEM excavator and building equipment parts supply unmatched durability, precision, and safety and security. By picking initial parts, drivers take full advantage of uptime, effectiveness, and ROI in sectors where dependability is non-negotiable.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of original spare parts Excavator Spare Parts construction machinery spare parts for

1. **Why should I choose original excavator spare parts over aftermarket alternatives?**

Original spare parts are engineered specifically for your excavator model, ensuring precise fitment, optimal performance, and longevity. They meet the manufacturer’s strict quality standards and undergo rigorous testing for durability under extreme conditions. Aftermarket parts may save costs upfront but often lack compatibility, reduce efficiency, and risk voiding warranties. Original parts minimize downtime and repair costs by extending equipment lifespan.

2. **How do I verify the authenticity of original excavator spare parts?**

Authentic parts come with unique identification markers like serial numbers, OEM logos, or holographic labels. Purchase only from authorized dealers or the manufacturer’s official channels. Cross-check part numbers with your equipment’s manual or the OEM’s online database. Reputable suppliers provide certificates of authenticity and warranty documentation. Avoid unverified sellers to prevent counterfeit parts that compromise safety and performance.

3. **Are original excavator spare parts readily available for older models?**

Most OEMs maintain an inventory of parts for legacy models, though lead times may vary. Contact authorized service centers or the manufacturer directly to confirm availability. If discontinued, OEMs often recommend compatible upgrades or alternatives. Planning maintenance in advance and sourcing parts through certified networks ensures timely access, even for older machinery.

4. **Do original spare parts come with a warranty?**

Yes, genuine parts typically include a manufacturer-backed warranty (e.g., 6–12 months), covering defects in materials or workmanship. The warranty terms vary by OEM and region, so review documentation carefully. Using original parts also preserves your equipment’s overall warranty, whereas aftermarket parts may void it. Keep purchase receipts and installation records for claims.

5. **How do I ensure compatibility when purchasing excavator spare parts?**

Always reference your equipment’s model number, serial number, and the part’s OEM code from the operator’s manual or parts catalog. Consult authorized dealers or OEM technical support for confirmation. Provide details like the excavator’s make, model year, and existing part specifications. Incorrectly sized or mismatched parts can cause operational failures, so double-check compatibility before purchasing.

(original spare parts Excavator Spare Parts construction machinery spare parts for )

REQUEST A QUOTE

RELATED PRODUCTS

Mini Excavator Hydraulic Repair Kit PC35 PC55 PC70 PC220 PC400-8 WA600-6 Main Piston Pump Parts For Komatsu

Low Moq Custom Logo Doosan Dx225 Excavator Sprocket Dragline Excavator Sprocket Chain Kobelco Excavator Sk200 Sprocket

Engineering Parts for Repair Parts on Road Milling Machine,Paver, Rollers, Excavators, Loaders Factory Direct For Slaes

Excavator Hydraulic Breaker Ear Plates Head Top Brackets