PRODUCT PARAMETERS

Description

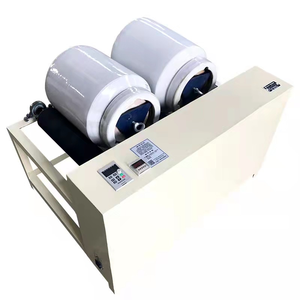

Brief introduction of Industrial Ball Milling Gold Ore Ball Mill For Mineral Ball Mill For Stone Gold

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Industrial Ball Milling Gold Ore Ball Mill For Mineral Ball Mill For Stone Gold refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Industrial Ball Milling Gold Ore Ball Mill For Mineral Ball Mill For Stone Gold

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Industrial Ball Milling Gold Ore Ball Mill For Mineral Ball Mill For Stone Gold)

Specification of Industrial Ball Milling Gold Ore Ball Mill For Mineral Ball Mill For Stone Gold

The Industrial Ball Milling Gold Ore Sphere Mill is a durable and high-performance grinding maker made for refining gold-bearing ores and stone gold in mining and mineral handling operations. Engineered for sturdiness and effectiveness, this sphere mill is ideal for reducing gold ore into great bits to help with gold extraction. Its durable building and construction makes sure reliable procedure under demanding problems, making it suitable for both small and massive mining jobs.

Secret specifications include a handling ability ranging from 0.5 to 100 bunches per hour, relying on the design. The mill is powered by a high-torque electric motor with power rankings from 15 kW to 450 kW, guaranteeing constant grinding performance. Operating at a rotational speed of 20– 30 RPM, it uses steel spheres as grinding media, which waterfall within the drum to crush and grind the ore. The drum, constructed from high-quality, wear-resistant steel, includes reinforced linings to lengthen life span. Standard drum diameters range from 900 mm to 4500 mm, with sizes varying proportionally to suit different throughput requirements.

The mill approves feed sizes up to 25 mm and supplies a carefully ground result of 0.074– 0.4 mm, flexible via discharge grate adjustments. It sustains both wet and dry grinding processes, with wet grinding preferred for gold ore to boost bit separation. The design includes a central lubrication system for simple upkeep and includes a closed-circuit operation to reduce dust and sound pollution. Safety and security devices, consisting of overload security and temperature level monitoring, make certain stable procedure.

Applications include grinding gold quartz ore, sulfide gold-bearing rocks, and second rock gold, in addition to various other non-ferrous steel ores. Its corrosion-resistant components and energy-efficient electric motor reduce functional costs while optimizing productivity. Personalized configurations are readily available to suit certain ore features or site needs. Constructed for durability and low upkeep, this commercial ball mill is an essential property for enhancing gold recovery procedures in mineral processing plants.

(Industrial Ball Milling Gold Ore Ball Mill For Mineral Ball Mill For Stone Gold)

Applications of Industrial Ball Milling Gold Ore Ball Mill For Mineral Ball Mill For Stone Gold

Industrial sphere milling is a vital process in the mining and mineral processing fields, specifically for applications entailing gold ore and rock gold extraction. The gold ore sphere mill, likewise known as a mineral round mill, is engineered to grind raw or smashed products right into finely powdered ore, making it possible for efficient splitting up of gold and various other important minerals. Its robust layout and adaptability make it vital across numerous phases of mineral handling.

One main application of commercial gold ore round mills remains in the comminution of gold-bearing ores. By decreasing ore bits to a consistent dimension, these mills improve the exposure of gold bits during succeeding leaching or cyanidation procedures, optimizing healing prices. They are just as important in refining refractory gold ores, where gold is encapsulated within sulfide minerals. Fine grinding liberates these entraped particles, enabling efficient chemical or thermal therapy.

Mineral round mills likewise play a crucial duty in gravity focus methods. After grinding, the homogenized slurry is fed right into gravity separation tools, such as centrifugal concentrators or trembling tables, where gold particles are sorted by density. In addition, these mills are utilized in crossbreed procedures, such as flotation protection and leaching, where bit size straight affects reagent effectiveness and removal returns.

Beyond gold, mineral sphere mills refine a variety of ores, including copper, lead-zinc, and iron, showing versatility. Their layout attributes include long lasting steel or rubber-lined grinding chambers to withstand rough materials, variable rate drives for exact control, and energy-efficient motors to lower functional expenses. Scalability enables personalization for small artisanal mining or big industrial procedures, while low-maintenance elements lessen downtime.

By ensuring consistent fragment size circulation and high throughput, industrial gold ore ball mills enhance mineral healing while reducing energy usage. Their reliability in rough mining settings and flexibility to diverse ore kinds make them a foundation of contemporary mineral processing, driving cost-efficient and sustainable removal of gold and various other metals.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Industrial Ball Milling Gold Ore Ball Mill For Mineral Ball Mill For Stone Gold

What is an industrial gold ore ball mill used for? An industrial gold ore ball mill is designed to grind gold-bearing ores and other mineral materials into fine powder, enabling efficient extraction of gold through subsequent processes like cyanidation or flotation. It is ideal for processing hard, abrasive ores such as quartz, sulfide, or oxidized gold ores, and is widely used in mining, metallurgy, and chemical industries for large-scale operations. The machine ensures consistent particle size reduction, critical for maximizing gold recovery rates.

How does a gold ore ball mill work? The ball mill operates by rotating a cylindrical drum filled with grinding media, typically steel balls. As the drum rotates, the balls cascade and impact the ore, crushing it into finer particles through friction and collision. The ground material is discharged through a sieve, controlling the final particle size. Adjustable rotation speed and grinding media size allow customization for different ore types and processing requirements.

What is the processing capacity of a mineral ball mill? Processing capacity varies by model, ranging from small-scale units (0.5–10 tons per hour) to industrial mills handling 100+ tons hourly. Capacity depends on factors like ore hardness, feed size, and desired output fineness. High-efficiency designs with optimized liners and energy-saving motors ensure maximum throughput while minimizing power consumption.

How to maintain a gold ore ball mill? Regular maintenance includes inspecting liners and grinding balls for wear, lubricating bearings and gears, and checking alignment. Worn components should be replaced promptly to avoid efficiency loss. Cleaning residual ore and ensuring proper sealing prevents contamination and corrosion. Scheduled downtime for comprehensive checks ensures long-term reliability and reduces unplanned outages.

What safety features are included? Industrial ball mills incorporate overload protection, emergency stop systems, and robust enclosures to contain debris. Safety guards cover rotating parts, and temperature sensors prevent overheating. Operators must follow protocols like wearing protective gear and avoiding open access during operation. Compliance with international safety standards minimizes risks of accidents or equipment failure.

(Industrial Ball Milling Gold Ore Ball Mill For Mineral Ball Mill For Stone Gold)

REQUEST A QUOTE

RELATED PRODUCTS

cement sag ball mill rubber liner plate for ball mill machine

Overflow ball mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement

Factory Direct Supply High Quality ball mill with rubber liner ball mill