PRODUCT PARAMETERS

Description

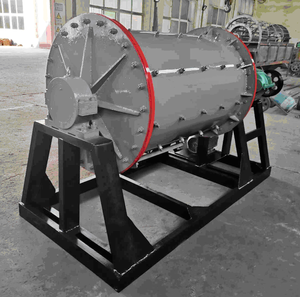

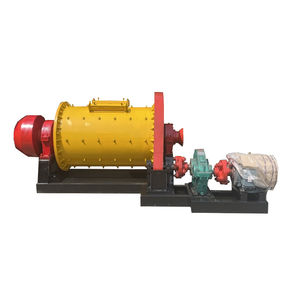

Brief introduction of Overflow Ball Mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Overflow Ball Mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Overflow Ball Mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Overflow Ball Mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement)

Specification of Overflow Ball Mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement

The Overflow Ball Mill is a durable and functional grinding mill developed for efficient handling of products such as hematite, iron ore, bentonite, limestone, and concrete in mining, mineral handling, and building and construction industries. This horizontal round mill runs by revolving a hollow trunnion, enabling ground product to overflow via the discharge end, making certain continual procedure and optimum particle dimension decrease. It is perfect for additional grinding applications, using adaptability to both damp and dry procedures.

Trick requirements include design sizes ranging from small-scale (0.5 t/h capability) to large commercial units (up to 150 t/h), driven by electric motors with power results from 18.5 kW to 4500 kW. The mill operates at a rotational speed of 15– 30 rpm, fitting feed bits up to 25 mm and creating carefully ground result in between 0.074 mm and 0.4 mm. The drum dimensions vary, with diameters of 900– 5500 mm and sizes of 1800– 8500 mm, customized to throughput needs.

Built from top notch, wear-resistant steel, the mill features a durable shell lined with exchangeable manganese or rubber liners to decrease wear. Grinding media, such as steel balls or poles, are picked based on product hardness– steel rounds for harder ores like hematite and rods for finer grinding of sedimentary rock or bentonite. The overflow style guarantees gentle handling of softer materials while preserving effectiveness for tough ores. Crucial components include big trunnion bearings for smooth turning, a gear-driven transmission system, and optional automation for specific control.

The mill masters grinding abrasive and non-abrasive products, making it appropriate for concrete clinker pulverization, iron ore beneficiation, and bentonite processing. Its advantages consist of high grinding performance, reduced power consumption, and very little upkeep due to streamlined style and robust building and construction. Personalized options consist of linings, media kind, drive systems, and auxiliary tools like classifiers or dirt collection agencies. Operational dependability is improved by corrosion-resistant materials and simple gain access to for inspection, making sure long service life.

Perfect for mining and concrete plants, the Overflow Sphere Mill integrates versatility with performance, delivering consistent outcomes throughout varied applications while supporting tailored solutions to meet particular grinding demands.

(Overflow Ball Mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement)

Applications of Overflow Ball Mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement

Overflow ball mills, grinding mills, and rod mills are essential devices in mining and industrial processing, offering flexible solutions for grinding materials like hematite, iron ore, bentonite, sedimentary rock, and concrete. These makers are designed to manage varying firmness degrees and bit dimensions, ensuring effective material processing for downstream applications.

** Hematite & Iron Ore Handling **: Overflow round mills master finely grinding hematite and iron ore to free iron bits for beneficiation. Their style allows constant procedure, making certain consistent outcome for magnetic splitting up or pelletization. Rod mills are excellent for main grinding of iron ore, using steel poles to break down rugged feed into smaller sized bits prior to further refinement in ball mills. This mix maximizes power performance and decreases over-grinding.

** Bentonite Grinding **: Bentonite’s swelling homes require mild grinding to preserve its structure. Overflow ball mills give controlled grinding, generating great bentonite powder for use in drilling liquids, binders, or sealers. The mill’s low-speed procedure protects against getting too hot, keeping the clay’s chemical integrity.

** Sedimentary Rock & Cement Production **: In cement production, limestone is a key basic material. Rod mills crush limestone to a coarse powder before mixing with other parts, while overflow sphere mills grind the mix right into great raw dish for kiln processing. For cement clinker grinding, overflow round mills guarantee consistent bit size circulation, enhancing concrete strength. Grinding mills, such as upright roller mills, are additionally extensively made use of in cement plants for their power effectiveness and capability to manage huge capabilities.

** Trick Benefits **: These mills are developed for durability, with wear-resistant linings and robust construction to deal with rough products. Overflow round mills protect against over-grinding by allowing discharge via overflow, while pole mills minimize penalties generation in rugged grinding phases. Their versatility across materials and procedures makes them essential in mining, construction, and concrete sectors.

By enhancing bit dimension control and energy usage, overflow sphere mills, rod mills, and grinding mills improve functional performance and product quality, supporting lasting resource usage in heavy markets. Their dependability and reduced maintenance needs further minimize downtime, ensuring constant production popular settings.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Overflow Ball Mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement

An Overflow Ball Mill is a grinding mill used primarily in mining and mineral processing to grind materials like hematite, iron ore, bentonite, limestone, and cement. Below are five frequently asked questions about this equipment:

**1. How does an Overflow Ball Mill work?**

The Overflow Ball Mill operates by rotating a cylinder filled with grinding media, typically steel balls. As the cylinder rotates, the balls lift and cascade, grinding the material into fine particles. The ground material is discharged through overflow when the pulp level exceeds the discharge trunnion’s height, ensuring continuous operation without external discharge mechanisms. This design is ideal for secondary grinding applications.

**2. Why is it suitable for grinding hematite, iron ore, bentonite, limestone, and cement?**

The mill’s robust construction and adjustable grinding parameters make it versatile. Hematite and iron ore require efficient fine grinding for beneficiation, which the overflow discharge facilitates. Bentonite and limestone, softer materials, are ground to controlled fineness without over-pulverization. For cement, the mill ensures uniform particle size distribution, critical for clinker grinding and strength development.

**3. What maintenance does an Overflow Ball Mill require?**

Regular lubrication of bearings and gears, inspection of liners and grinding media for wear, and monitoring of motor performance are essential. Maintenance intervals depend on operational intensity, but scheduled downtime for part replacement ensures longevity. The design minimizes abrupt failures, supporting predictable upkeep.

**4. How does it compare to a Rod Mill?**

Unlike Rod Mills, which use rods for grinding and suit coarse primary grinding, Overflow Ball Mills use balls for finer grinding. The overflow mechanism allows finer particle discharge, making it better for secondary grinding. Rod Mills excel in preventing over-grinding for brittle materials, while Ball Mills offer higher efficiency for harder ores.

**5. Is the Overflow Ball Mill energy-efficient?**

Yes. Its low-speed rotation reduces energy consumption, and the overflow design prevents material backup, optimizing grinding efficiency. Advanced models feature variable-speed drives and automated controls to further minimize power use, making it cost-effective for large-scale operations processing abrasive or hard materials.

(Overflow Ball Mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement)

REQUEST A QUOTE

RELATED PRODUCTS

Coal mill in thermal power plant centrifugal fan oil filter element spare parts ball mill coal mill to generate electricity

High quality grinding ball mill part durable ball mill pinion shaft

1 Ton Per Hour Gold Ore Ball Mill And Spare Parts Milling Balls For Mining

Superir Hot Low Ball Mill Grinding Machine With Lower Starting Power

Casting High Quality and Long Use Time Ball Mill Diaphragm Excellent Performance Ball Mill Spare Parts Ball Mill Liners