PRODUCT PARAMETERS

Description

Brief introduction of F&D 17mm low ball mill grinding ball higher quality

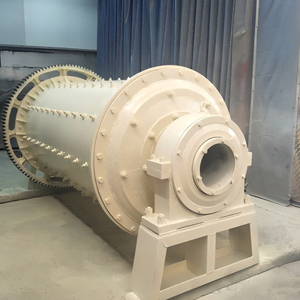

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. F&D 17mm low ball mill grinding ball higher quality refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of F&D 17mm low ball mill grinding ball higher quality

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(F&D 17mm low ball mill grinding ball higher quality)

Specification of F&D 17mm low ball mill grinding ball higher quality

The F&D 17mm low round mill grinding sphere is developed for high-performance grinding applications. It is made from exceptional products to guarantee toughness and efficiency. The 17mm size fits industrial machinery requiring small-sized media for great grinding. These balls are crafted with high-grade steel or alloy blends for consistent hardness and put on resistance. The product composition minimizes contortion during procedure. This expands the product’s life expectancy even under heavy use.

The production process includes advanced warmth treatment. This step boosts surface hardness and core durability. The balanced solidity avoids fracturing or damaging. It additionally preserves grinding effectiveness with time. Each sphere undertakes strict top quality look for size harmony and surface smoothness. Specific dimensions minimize irregular wear in mills. This assists preserve steady grinding performance.

These grinding balls are ideal for refining minerals, concrete, and porcelains. They carry out well in both damp and completely dry milling atmospheres. The low wear price minimizes contamination threats in processed products. This is essential for sectors requiring high-purity results. The spheres’ regular density ensures foreseeable grinding behavior. Operators can achieve desired fragment sizes with fewer adjustments.

The F&D 17mm rounds are economical because of their long life span. Reduced replacement frequency reduces downtime and upkeep prices. Their compatibility with numerous mill kinds adds adaptability. They work efficiently in sphere mills, rotary equipment, and resonance mills.

Quality control consists of testing for solidity, influence resistance, and chemical security. Random set tasting guarantees conformity with sector requirements. The surface area is treated to resist rust and chain reaction. This makes them appropriate for severe or abrasive environments.

The design focuses on taking full advantage of get in touch with surface area throughout grinding. This improves product malfunction prices. Power consumption is enhanced without compromising result top quality. The balls’ smooth surface minimizes friction-generated heat. This secures both the grinding media and the mill cellular lining.

Industries like mining, building and construction, and chemical handling benefit from these grinding balls. They take care of materials varying from soft powders to tough ores. The F&D 17mm spheres are packaged securely to avoid damage throughout transit. Bulk purchasing options are offered for large operations. Personalized specs can be organized to satisfy special operational needs.

Trustworthy efficiency and rigorous quality assurance make these grinding balls a sensible choice. They address common difficulties in product handling. The focus on accuracy and resilience guarantees constant outcomes throughout applications.

(F&D 17mm low ball mill grinding ball higher quality)

Applications of F&D 17mm low ball mill grinding ball higher quality

The F&D 17mm low sphere mill grinding sphere is developed for industrial grinding jobs. It works in mining, concrete manufacturing, chemical handling, and power plants. Its little 17mm size makes it efficient for breaking down materials right into great fragments. This dimension makes certain regular grinding cause machines like round mills and vertical mills.

The grinding round utilizes high chromium steel. This product improves solidity and use resistance. It lasts longer than regular steel balls. High chromium web content minimizes breakage during heavy usage. This reduces substitute expenses and downtime. The spheres keep shape under high pressure. This maintains grinding efficiency steady gradually.

Mining procedures benefit from these balls. They grind ores like gold, copper, and iron. Regular particle dimension helps in mineral splitting up. Cement plants utilize them to crush resources and clinker. Uniform grinding enhances cement top quality. Chemical sectors rely on them for refining powders and pigments. The spheres handle corrosive materials without weakening.

Power plants utilize these spheres to pulverize coal. Effective coal grinding makes certain much better combustion in central heating boilers. This decreases fuel waste and exhausts. The rounds’ wear resistance is critical below. Coal grinding develops severe friction. Regular balls wear down quickly. The F&D 17mm spheres sustain longer.

These grinding spheres cut functional prices. Their toughness suggests less substitutes. Much less downtime increases efficiency. Power usage goes down because the balls work efficiently. Upkeep requires decrease. Workers invest much less time checking and altering worn balls.

The smooth surface area of the F&D 17mm rounds protects against material contamination. This is essential in food handling or drugs. Also use avoids presenting impurities. The round shape stays precise after repeated usage. This guarantees consistent performance in precise grinding jobs.

The spheres match wet and dry grinding. They carry out in rough problems such as high warm or wetness. This adaptability makes them useful across industries. They fit usual grinding equipment without adjustment.

Higher quality comes from sophisticated production. Regulated heat therapy reinforces the steel framework. Precision molding makes certain consistent dimension and weight. Extensive testing checks firmness, effect resistance, and use prices. Each batch meets strict industry requirements.

The F&D 17mm low ball mill grinding sphere equilibriums performance and price. Its design concentrates on dependability and performance. Industries requiring sturdy, top notch grinding media discover it a useful option.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of F&D 17mm low ball mill grinding ball higher quality

What material is the F&D 17mm low ball mill grinding ball made of? The grinding balls use high-grade steel alloys. These alloys combine strength and wear resistance. Carbon, chromium, and manganese are main components. These elements boost hardness and durability. The material choice ensures reliable performance in tough grinding conditions.

How does the heat treatment process improve quality? The balls undergo quenching and tempering. Quenching involves heating followed by rapid cooling. This step increases hardness. Tempering reduces brittleness. This balance prevents cracks under heavy use. The result is a longer-lasting product with consistent grinding efficiency.

What industries use these grinding balls? Mining, cement production, and chemical processing commonly use them. They grind raw materials like ores and clinker. They suit applications needing fine, uniform particle sizes. Their design works well in low-speed ball mills. These mills require grinding media that withstand repeated impact without breaking.

Why choose F&D balls over high-chrome alternatives? High-chrome balls may crack under heavy impact. F&D balls handle stress better due to their material mix. They wear evenly over time. This reduces replacement frequency. Lower maintenance costs and higher productivity make them a practical choice for many operations.

How do I maintain these grinding balls? Inspect them regularly for wear or damage. Remove broken pieces promptly to avoid mill damage. Clean the mill chamber periodically. Check ball size uniformity. Store unused balls in a dry environment. Follow the manufacturer’s guidelines for optimal performance. Proper care extends their lifespan and maintains grinding efficiency.

(F&D 17mm low ball mill grinding ball higher quality)

REQUEST A QUOTE

RELATED PRODUCTS

Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover

High-Quality High Manganese Steel Ball Mill Liners Reliable Wear Spare Parts for Ball Mills

Rotary kiln and cement ball mill spare pasts wheel and ring gear casting girth gear large steel spur gear

Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts

Most Searched for Tool 2023 OEM Low Good Quality Custom Liners Ball Mill Parts Cement Making Wear Resistant High Chrome