PRODUCT PARAMETERS

Description

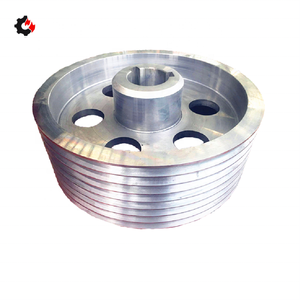

Brief introduction of High quality ball grinding mill ball mill offer

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. High quality ball grinding mill ball mill offer refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of High quality ball grinding mill ball mill offer

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(High quality ball grinding mill ball mill offer)

Specification of High quality ball grinding mill ball mill offer

High-quality sphere grinding mills provide dependable efficiency in numerous industrial applications. These equipments process hard products right into great powders efficiently. The design focuses on toughness and efficiency. Trick parts include a robust steel framework and state-of-the-art grinding media. The grinding media contains stainless-steel or ceramic balls picked for hardness and use resistance.

The ball mill operates through a revolving cyndrical tube driven by an effective electric motor. The cyndrical tube consists of grinding balls and resources. As the cyndrical tube rotates, the rounds hit the product, simplifying right into smaller sized fragments. The rotation rate adjusts to manage the grinding excellence. A higher rate generates finer powder.

This tools deals with materials like ores, ceramics, and chemicals. It works well in mining, concrete production, and drugs. The internal lining uses manganese steel or rubber to lower wear and noise. Sealed bearings prevent dirt entrance, ensuring smooth operation. A cooling system takes care of heat during long terms, avoiding overheating.

The motor makes use of energy-efficient modern technology to reduce power usage. Upkeep is simple as a result of easily accessible components. Lubrication factors are plainly noted for easy maintenance. Security functions consist of emergency situation quits and overload defense. These mills meet international safety standards.

Customization alternatives are readily available. Individuals select cylinder size, motor power, and lining product based on requirements. Technical assistance aids pick the best design. Setup services guarantee correct arrangement. Training covers operation and maintenance essentials.

Grinding fineness varieties from 50 to 300 mesh, adjustable via screen changes. The machine deals with both dry and wet grinding. Wet grinding blends materials with water or solvents for slurry processing. Release approaches consist of overflow or grate designs, relying on material type.

Extra parts like liners and bearings are widely offered. Normal inspections prolong the machine’s life-span. Replacement intervals for wear components depend on use strength. Operational expenses remain low due to very little downtime and energy performance.

(High quality ball grinding mill ball mill offer)

Applications of High quality ball grinding mill ball mill offer

Top quality sphere grinding mills manage hard products in lots of sectors. These devices grind ores, cement, chemicals, ceramics. They damage big fragments into great powders. This procedure matters for making products function right. Mining operations utilize these mills to draw out steels from ore. Concrete plants depend on them to produce regular raw meal. Chemical factories need uniform powders for responses. Ceramic producers achieve smooth structures with these tools.

The round mill works by rotating a chamber with steel spheres inside. Products enter the chamber. Steel rounds go down and ram the material. Rubbing and impact grind the material over time. The result is a finely ground powder. Adjusting rotation rate regulates fragment size. Faster turning produces finer powders. Slower turning maintains particles coarser.

These mills utilize solid materials for building. Thick steel coverings protect against wear. Reinforced bearings handle heavy loads. Secured designs stop dirt leakages. This reduces waste and safety and security dangers. Operators accessibility components quickly for cleansing. Replacement parts fit without personalized adjustments.

Maintenance remains basic. Normal checks on lubrication systems avoid breakdowns. Used balls obtain exchanged promptly. Control systems keep an eye on temperature and resonance. Alerts inform operators prior to problems aggravate. Downtime stays low. Manufacturing keeps running efficiently.

Power use stays effective. Advanced motors cut power consumption. Warmth from grinding obtains reused. This reduces operating costs. Less power waste assists firms meet budget plans. Constant outcome minimizes product rework.

These mills fit small labs and huge factories. Compact models match minimal rooms. Durable variations manage 24/7 mining operations. Custom configurations match particular material demands. Wet grinding blends liquids with powders. Dry grinding procedures moisture-sensitive materials.

Top quality ball mills offer reliable efficiency. They adjust to various markets. Their design concentrates on durability and simplicity of use. Companies conserve cash with efficient procedure. Employees remain secure with built-in safeguards. Products satisfy high quality criteria every single time.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High quality ball grinding mill ball mill offer

A high-quality ball grinding mill crushes materials into fine powders. It uses rotating cylinders filled with grinding media like steel balls. Industries needing precise particle sizes rely on this equipment for consistent results. Common uses include mining, cement production, and chemical processing.

What materials can a ball grinding mill process? It handles hard and brittle materials such as ores, ceramics, and chemicals. Wet or dry grinding methods suit different material types. The machine adjusts rotation speed and ball size for varying hardness levels. This flexibility makes it suitable for multiple industries.

How does a ball mill ensure even grinding? The cylinder rotates, causing balls to lift and drop onto materials. Impact and friction break particles down uniformly. Internal compartments or classifiers separate finer particles from coarse ones. This process repeats until desired fineness is achieved.

What advantages does a high-quality ball mill offer over regular mills? It provides higher efficiency due to optimized design and durable materials. Advanced models reduce energy consumption by up to 30%. Precision engineering minimizes wear and tear, lowering maintenance costs. Consistent output quality ensures reliable performance for long-term projects.

How do I maintain a ball grinding mill? Regular lubrication of moving parts prevents friction damage. Inspect liners and grinding media for wear every few weeks. Replace worn balls to maintain grinding efficiency. Clean the mill after processing abrasive materials to avoid contamination. Follow the manufacturer’s guidelines for specific maintenance schedules.

Can a ball mill handle both continuous and batch operations? Yes. Continuous operation feeds materials nonstop for large-scale production. Batch processing allows smaller quantities with precise control. Operators switch modes based on project needs. This adaptability makes the equipment suitable for varied production demands.

(High quality ball grinding mill ball mill offer)

REQUEST A QUOTE

RELATED PRODUCTS

Ball mill Spare parts ball mill liner accessories ball mill liner plate

spare parts liner and steel balls gold ore stone ball grinding machine with ball mill

Rotary kiln and cement ball mill spare pasts wheel and ring gear casting girth gear large steel spur gear

Made in Customizable Rotary Kiln Spare Parts 42CrMo4 Segmented Rotary Kiln Girth Ball Mill Ring Gear For Cement Plant

Low worth buying products Mining Grinding Mill Trommel Scrubber Wear Parts Rubber Ball Mill Liner For