PRODUCT PARAMETERS

Description

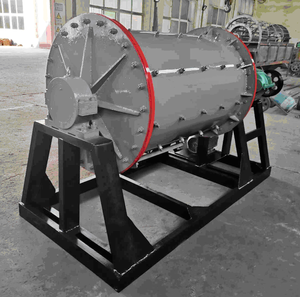

Brief introduction of Ball Mill Liner Grinding Machinery Spare Part Cement Ore Mineral Mill Wear Part Liner

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Ball Mill Liner Grinding Machinery Spare Part Cement Ore Mineral Mill Wear Part Liner refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Ball Mill Liner Grinding Machinery Spare Part Cement Ore Mineral Mill Wear Part Liner

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Ball Mill Liner Grinding Machinery Spare Part Cement Ore Mineral Mill Wear Part Liner)

Specification of Ball Mill Liner Grinding Machinery Spare Part Cement Ore Mineral Mill Wear Part Liner

The Ball Mill Liner is a critical component in grinding machinery, specifically designed to protect the inner shell of the ball mill from wear and tear caused by the grinding process. These liners are essential for maintaining the efficiency and longevity of ball mills, which are widely used in industries such as cement production, mineral processing, and ore beneficiation. Made from high-quality materials, the liners are engineered to withstand the harsh conditions of grinding operations, including abrasion, impact, and corrosion.

The liners are typically manufactured from durable materials such as high-chrome steel, manganese steel, or rubber, depending on the specific application and operational requirements. High-chrome steel liners are known for their exceptional hardness and resistance to abrasion, making them ideal for grinding abrasive materials like cement clinker and ores. Manganese steel liners, on the other hand, offer excellent impact resistance, making them suitable for applications involving heavy impacts. Rubber liners are often used in wet grinding processes due to their ability to reduce noise and absorb impact energy, thereby extending the lifespan of the mill.

The design of the Ball Mill Liner plays a crucial role in optimizing the grinding process. The shape and configuration of the liners influence the trajectory of the grinding media, ensuring efficient grinding and minimizing energy consumption. Common designs include wave liners, step liners, and ribbed liners, each tailored to specific grinding conditions and material characteristics. Additionally, the liners are designed for easy installation and replacement, reducing downtime and maintenance costs.

In summary, the Ball Mill Liner is an indispensable wear part in grinding machinery, offering protection, durability, and performance optimization. Its high-quality construction and thoughtful design make it a reliable choice for industries dealing with cement, minerals, and ores, ensuring smooth and efficient grinding operations while minimizing operational costs.

(Ball Mill Liner Grinding Machinery Spare Part Cement Ore Mineral Mill Wear Part Liner)

Applications of Ball Mill Liner Grinding Machinery Spare Part Cement Ore Mineral Mill Wear Part Liner

Ball mill liners are essential components in grinding machinery, particularly in industries such as cement production, mineral processing, and ore beneficiation. These liners serve as protective layers inside the ball mill, shielding the mill’s inner shell from the intense wear and impact caused by grinding media and raw materials. Their primary function is to enhance the efficiency and longevity of the grinding process while minimizing maintenance costs.

In cement manufacturing, ball mill liners play a critical role in grinding clinker, gypsum, and other additives into fine powder, which is then used to produce cement. The liners must withstand high abrasion and impact forces, ensuring consistent grinding performance and reducing downtime. Similarly, in mineral processing, these liners are used to grind ores such as gold, copper, and iron, facilitating the extraction of valuable metals. The durability and resistance of the liners to wear are crucial in maintaining operational efficiency in these demanding environments.

Ball mill liners are also widely used in the mining industry, where they help process raw materials into finer particles for further refinement. Their ability to endure harsh conditions, such as extreme temperatures and corrosive substances, makes them indispensable in this sector. Additionally, these liners are designed to optimize the grinding process by improving the trajectory of grinding media, ensuring better particle size reduction and energy efficiency.

The materials used in manufacturing ball mill liners, such as high-chrome steel, manganese steel, and rubber, are selected based on the specific application and operational requirements. High-chrome liners, for instance, are ideal for abrasive environments, while rubber liners are preferred for their noise reduction and impact resistance properties.

Overall, ball mill liners are vital wear parts that contribute significantly to the performance and productivity of grinding machinery. By reducing wear and tear, extending equipment lifespan, and enhancing grinding efficiency, they are indispensable in industries that rely on fine grinding processes.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Ball Mill Liner Grinding Machinery Spare Part Cement Ore Mineral Mill Wear Part Liner

Ball mill liners are essential components in grinding machinery, especially in cement, ore, and mineral processing industries. They protect the mill shell from wear and tear caused by the grinding process and ensure efficient operation. Here are five frequently asked questions about ball mill liners:

1. **What is the purpose of a ball mill liner?**

Ball mill liners serve as protective layers inside the grinding mill. They shield the mill shell from direct impact and abrasion caused by grinding media (balls) and the material being processed. Liners also enhance grinding efficiency by optimizing the movement of the grinding media and material.

2. **What materials are used to make ball mill liners?**

Ball mill liners are typically made from high-quality, wear-resistant materials such as high-chrome steel, manganese steel, rubber, or composite materials. The choice of material depends on the application, with high-chrome steel being ideal for abrasive environments and rubber liners preferred for noise reduction and corrosion resistance.

3. **How do I choose the right liner for my ball mill?**

Selecting the right liner depends on factors such as the type of material being ground, the size of the mill, and the operating conditions. For example, high-chrome liners are suitable for hard and abrasive materials, while rubber liners are better for wet grinding processes. Consulting with a manufacturer or supplier can help you make the best choice.

4. **How often should ball mill liners be replaced?**

The lifespan of ball mill liners varies depending on the material, operating conditions, and maintenance practices. Regular inspections are crucial to identify signs of wear, such as cracks or thinning. On average, liners may need replacement every 6 to 12 months, but this can vary significantly.

5. **Can ball mill liners be customized?**

Yes, ball mill liners can be customized to fit specific mill dimensions and operational requirements. Customization options include size, shape, material, and design features like lifter bars or wave patterns, which can improve grinding efficiency and reduce energy consumption.

In summary, ball mill liners are critical for protecting grinding machinery and ensuring optimal performance. Choosing the right material, monitoring wear, and considering customization can significantly enhance the lifespan and efficiency of your mill.

(Ball Mill Liner Grinding Machinery Spare Part Cement Ore Mineral Mill Wear Part Liner)

REQUEST A QUOTE

RELATED PRODUCTS

spare parts liner and steel balls gold ore stone ball grinding machine with ball mill

Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From

Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding

Overflow ball mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement

Factory Spare Parts For Mining Crusher Precision Ball Mill Liner Impact Crusher Hammer Crusher For Stone Crushing