PRODUCT PARAMETERS

Description

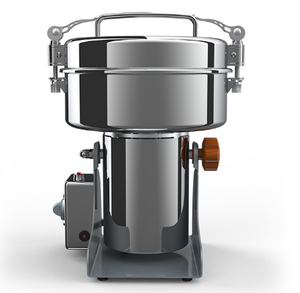

Brief introduction of Ball Mill Powder Mill for Mineral Processing Small Overflow Type Mixed Mercury High Manganese Steel Ball Mill

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Ball Mill Powder Mill for Mineral Processing Small Overflow Type Mixed Mercury High Manganese Steel Ball Mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Ball Mill Powder Mill for Mineral Processing Small Overflow Type Mixed Mercury High Manganese Steel Ball Mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Ball Mill Powder Mill for Mineral Processing Small Overflow Type Mixed Mercury High Manganese Steel Ball Mill)

Specification of Ball Mill Powder Mill for Mineral Processing Small Overflow Type Mixed Mercury High Manganese Steel Ball Mill

The Round Mill Powder Mill for Mineral Handling, Small Overflow Type Mixed Mercury High Manganese Steel Round Mill, is crafted for efficient grinding in mineral extraction and ore handling applications. Made with a portable footprint, this mill is perfect for small operations needing reliable performance. Its overflow discharge system makes sure fine grinding by allowing ground material to leave via the hollow shaft once it gets to a specific degree, maximizing particle size uniformity. The mill’s building and construction makes use of high manganese steel for essential parts, including liners and grinding media, guaranteeing exceptional wear resistance and expanded life span in rough settings. This durability minimizes downtime and maintenance prices. The grinding chamber is fortified with combined mercury-grade products, enhancing corrosion resistance in processes entailing reactive substances or amalgamation strategies. The mill operates at a rotational speed of about 36 RPM (70-80% of important speed), well balanced to take full advantage of effect and grinding efficiency. Powered by a 5.5 kW to 22 kW electric motor (relying on arrangement), it sustains constant procedure with a handling capability ranging from 0.5 to 5 heaps per hour. The drum dimensions normally span 900 mm in diameter and 1800 mm in length, fitting diverse feed dimensions. Grinding media consists of high manganese steel rounds in sizes from 20 mm to 100 mm, tailored to accomplish target excellence. Suitable for wet grinding procedures, it is widely utilized in gold, silver, copper, and various other ore processing, specifically where combinations or chemical leaching is utilized. The durable design makes certain security, with an overall weight of 2 to 10 tons based upon dimension. Operational advantages consist of reduced energy usage, consistent bit output, and flexibility to both open and closed-circuit systems. Safety functions focus on safe sealing to prevent leakage, vital in managing unsafe materials. This mill is an affordable remedy for mineral processors focusing on durability, effectiveness, and precision in small-scale procedures.

(Ball Mill Powder Mill for Mineral Processing Small Overflow Type Mixed Mercury High Manganese Steel Ball Mill)

Applications of Ball Mill Powder Mill for Mineral Processing Small Overflow Type Mixed Mercury High Manganese Steel Ball Mill

The Applications of Ball Mill Powder Mill for Mineral Handling Small Overflow Kind Mixed Mercury High Manganese Steel Sphere Mill are designed to meet the strenuous needs of contemporary mineral handling procedures. This customized equipment integrates innovative engineering with durable materials to enhance grinding effectiveness, specifically in small-scale or specialized applications. The overflow-type discharge mechanism makes certain a better work by permitting ground product to leave when it reaches a certain slurry level, protecting against over-grinding and developing particle dimension uniformity.

Suitable for processing metal and non-metallic ores, this sphere mill excels in handling minerals like gold, silver, copper, and lead-zinc. Its compatibility with mixed mercury processes makes it an essential tool in gold extraction, where mercury amalgamation is utilized to recoup fine gold particles from ore. The high manganese steel building and construction of the lining plates and grinding media guarantees remarkable wear resistance, prolonging the mill’s life-span even when refining unpleasant products. This resilience lowers maintenance downtime and functional costs.

The small, small-scale design is tailored for research laboratories, pilot plants, or mining procedures with restricted space. It supports both damp and completely dry grinding, supplying flexibility for varied mineral handling operations. The overflow discharge system promotes a consistent flow of slurry, minimizing energy usage while preserving high throughput. Furthermore, the high manganese steel parts stand up to deformation under heavy loads, making sure constant performance in continual operations.

Environmental and safety considerations are attended to with durable sealing devices to include mercury vapors throughout combinations, aligning with contemporary security standards. This sphere mill is likewise ideal for processing commercial minerals like quartz, feldspar, and limestone, where accurate fragment size control is vital. By incorporating dependability, adaptability, and performance, this sphere mill serves as a versatile service for mineral cpus seeking to improve recuperation rates and operational sustainability in challenging atmospheres.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Ball Mill Powder Mill for Mineral Processing Small Overflow Type Mixed Mercury High Manganese Steel Ball Mill

What is the primary application of the Small Overflow Type Ball Mill in mineral processing? This ball mill is designed for grinding and blending minerals, particularly in small-scale operations where fine particle size is critical. It is commonly used to process gold-bearing ores through mercury amalgamation, where the overflow design ensures continuous discharge of ground material, preventing over-grinding and enabling efficient recovery of precious metals.

Why is high manganese steel used in the construction of this ball mill? High manganese steel offers exceptional durability and wear resistance, critical for handling abrasive minerals. Its unique ability to harden under impact reduces wear on liners and grinding balls, extending operational life. This material is ideal for environments with constant friction and heavy loads, ensuring cost-effective performance in prolonged mineral processing tasks.

How does the overflow-type design enhance mineral processing efficiency? The overflow mechanism allows finely ground particles to exit the mill continuously, maintaining optimal grinding conditions. This prevents material buildup, reduces energy consumption, and ensures consistent particle size distribution. It is especially effective for processing softer ores or when a finer product is required, improving downstream recovery processes like mercury amalgamation or leaching.

What maintenance practices are essential for this ball mill’s longevity? Regular lubrication of bearings and gears, inspection of bolts and liners for wear, and timely replacement of high-manganese steel components are crucial. Monitoring the grinding media (balls) for size and shape consistency ensures efficient operation. Cleaning residual slurry and checking seals prevent corrosion and leakage, particularly when processing mercury-containing materials.

What safety precautions should operators follow when using this ball mill? Proper ventilation is mandatory to mitigate mercury vapor exposure during amalgamation. Operators must wear PPE, including gloves and respirators, when handling materials or maintaining the mill. Ensure the machine is securely grounded and regularly inspect electrical components. Always shut down the mill and follow lockout-tagout procedures during maintenance to avoid mechanical hazards.

(Ball Mill Powder Mill for Mineral Processing Small Overflow Type Mixed Mercury High Manganese Steel Ball Mill)

REQUEST A QUOTE

RELATED PRODUCTS

Diesel Engine Ball Mill Provided AC Motor Customizable Mining Equipment Gold Ball Mill for Ball Milling Machine

Gear Shaft For Ball Mill Spline Gear Shaft Mining Spare Parts Gear Shaft For Gearbox

s Large diameter ball mill bull gear forging ZG45 cement rotary kiln spur girth ring

Electromagnetic vibrating feeder for feeder to ball mill from hopper

Factory custom mining equipment ball mill drive parts accessories Hollow shaft