PRODUCT PARAMETERS

Description

Brief introduction of Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From

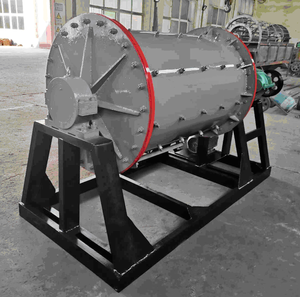

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From )

Specification of Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From

The ceramic liner ball mill machine is an essential tool in laboratory settings for grinding various types of materials, including spices, powders, and metals. The machine uses ceramic balls to grind the material into fine particles, ensuring consistency and purity in the final product.

The ball mill consists of a rotating chamber with ceramic balls that move back and forth to grind the material. The chamber is typically made of materials such as cast iron or steel, and the balls can be of different sizes depending on the size of the material being ground. The balls used in the ball mill are designed to reduce friction and wear on the machine’s moving parts.

The ceramic liner ball mill is highly efficient and accurate in its grinding process. It is able to grind materials at high speeds without overheating, which helps to prolong the lifespan of the machine. Additionally, the ceramic balls used in the ball mill are resistant to scratches and chips, making them ideal for use in continuous operation.

One of the key advantages of the ceramic liner ball mill is its ability to handle small and large materials. The machine can grind even the smallest amount of material, while also handling larger quantities with ease. This makes it a versatile tool that can be used in a variety of laboratory settings.

Another advantage of the ceramic liner ball mill is its low maintenance cost. The machine does not require regular cleaning or lubrication, which saves time and money in the long run. Additionally, the ceramic balls used in the ball mill are made from durable materials that can withstand frequent use, reducing the need for costly replacements.

In conclusion, the ceramic liner ball mill machine is a reliable and effective tool for grinding a wide range of materials. Its unique design features, such as the use of ceramic balls and low maintenance costs, make it an excellent choice for laboratory settings. Whether you’re working with spices, powders, or metals, the ceramic liner ball mill will help you achieve consistent and precise results every time.

(Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From )

Applications of Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From

Ceramic Liner Ball Mill Machine is a popular ball grinding mill used in small laboratories for grinding various materials, such as clay, sand, and steel powder. This type of mill has several applications due to its ability to grind materials efficiently and at low speeds.

One of the most important applications of ceramic liner ball mill machine is in laboratory experiments where precise measurements of small quantities of materials need to be made. The mill can accurately grind samples to very fine particle sizes, making it ideal for research and development work.

Another application of ceramic liner ball mill machine is in industrial settings where material processing requires precise grinding of powders and granules. In this case, the mill can be used to grind a wide range of materials, including metals, ceramics, and glass.

In addition, the mill can also be used in food industry for grinding wheat flour, rice flour, and other grains. It can help improve the texture and consistency of the products by reducing their porosity and increasing their nutritional value.

The ceramic liner ball mill machine is also widely used in mining and recycling industries where minerals and rocks are ground into smaller particles for further processing or use in manufacturing. This process is called mineral liberation or grinding.

Overall, the ceramic liner ball mill machine offers several applications across different industries and sectors. Its efficient grinding capabilities make it an essential tool for precision measurement, material processing, and scientific research.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From

1. What is a ceramic liner ball mill machine? A ceramic liner ball mill machine is a type of grinding equipment that uses ceramic balls to grind materials. It is typically used in small laboratory settings, such as universities and research institutions.

2. How does the ceramic liner ball mill work? The ceramic liner ball mill works by using a series of rotating cylindrical balls made of ceramic material. As the balls rotate, they collide with the grinding medium, causing it to grind the materials.

3. Is the ceramic liner ball mill suitable for all types of materials? No, the ceramic liner ball mill is not suitable for all types of materials. It is only recommended for materials that are harder than ceramics or those that can withstand high temperatures.

4. Can I use the ceramic liner ball mill for dry grinding? Yes, you can use the ceramic liner ball mill for dry grinding. Dry grinding involves removing moisture from the grinding medium without changing the composition of the material being ground.

5. How long do I need to run the ceramic liner ball mill? The length of time you need to run the ceramic liner ball mill will depend on the size of the grinding material being ground and the capacity of the machine. As a general rule, most ceramic liner ball mills require at least 8 hours of operation per day.

(Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From )

REQUEST A QUOTE

RELATED PRODUCTS

Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding

Factory custom mining equipment ball mill drive parts accessories Hollow shaft

Factory Spare Parts For Mining Crusher Precision Ball Mill Liner Impact Crusher Hammer Crusher For Stone Crushing

High Chrome manganese Alloy cement quartz copper and gold ore ball mill liner wear plate spare parts

Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill