PRODUCT PARAMETERS

Description

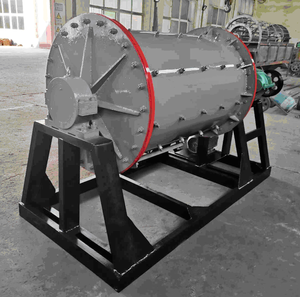

Brief introduction of Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts)

Specification of Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts

Ball mill is one of the most commonly used grinding machines in industries such as mining, cement production, and chemical processing. It is an important component of the crushing process that is responsible for breaking down large rocks into smaller pieces. To ensure optimal performance of ball mills, it is essential to specify certain parts.

One critical part of a ball mill is the grid plate. The grid plate is a flat plate made of steel or other materials and used to suspend balls within the mill. It is designed to maintain a consistent distance between the balls and prevent them from entering each other’s way during rotation. The grid plate is typically made of steel and has small grooves on its surface to facilitate ball feeding.

Another critical part of a ball mill is the liner plate. The liner plate is a flat plate made of metal that is used to line the gap between the grinding cups in the ball mill. It is designed to protect the grinding cups from damage and keep them lubricated. The liner plate is typically made of stainless steel or other materials and is easy to clean and maintain.

The liner plate also plays a crucial role in preventing blockages in the ball mill. If there is too much debris in the gap between the grinding cups, it can cause blockages and disrupt the rotation of the mill. Therefore, it is essential to regularly inspect and clean the liner plate to prevent blockages.

Finally, the ball mill needs the correct type of grinding steel balls. These balls must be properly ground and have a specific hardness and wear resistance to ensure that they do not wear out quickly and reduce the lifespan of the mill. Different types of grinding steel balls are available, including rod grinding balls, balls with boron carbide particles, and balls with microcrystalline silica particles. It is essential to select the right type of grinding steel balls based on the application requirements of the mill.

In conclusion, specifying the correct parts of a ball mill is critical to ensuring optimal performance and longevity of the machine. The grid plate, liner plate, and grinding steel balls are all essential components of the ball mill, and proper specification ensures that these components function correctly and efficiently. Therefore, it is important to carefully review and choose the appropriate specifications for your ball mill.

(Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts)

Applications of Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts

Crusher plant parts, such as ball mill parts, grinding steel balls and liner plates, play critical roles in the operation of ball mills. Ball mill parts are essential components that ensure smooth operation of the ball mill, and they are vital for preventing clogging and damage to the grinding chamber. The grinding steel balls are used to grind materials into smaller particles, while the liner plate provides stability to the grinding system and ensures even distribution of feed.

The ball mill grid plate is another important component of the crushing plant. It consists of several grids of steel plates spaced apart, which act as barriers between the feed material and the grinding media. The grid plates prevent the entering of foreign matter into the grinding chamber, ensuring the consistency of the grinding process. Additionally, the grid plates help maintain even pressure across the feeding material, ensuring consistent acceleration during rotation.

The liner plate is a crucial part of the grinding process. It acts as a shock absorber and helps prevent the wear and tear on the grinding media, reducing downtime and increasing efficiency. The liner plate also plays an important role in regulating the speed of rotation, ensuring that the material is ground at a consistent rate.

In conclusion, applications of crushing plant parts, including ball mill parts, grinding steel balls, and liner plates, are significant in optimizing the performance of ball mills. These components work together to provide smooth operation, prevent clogging, ensure even distribution of feed, and maintain even pressure across the feeding material. By selecting appropriate crushing plant parts, it is possible to improve the efficiency and durability of ball mills, ultimately leading to better plant performance.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts

1. What are grinding steel balls?

Grinding steel balls are made from high-strength steels that have been specifically designed to withstand the demands of ball milling operations. They are available in different sizes and shapes, such as rod balls, cone balls, or transitional balls.

2. What are the benefits of using grinding steel balls in ball milling?

The main benefit of using grinding steel balls is their superior performance in ball milling applications. They are able to efficiently grind materials with high hardnesses and a wide range of particle sizes, which results in better productivity and reduced wear on the mill. Additionally, they are corrosion-resistant and can withstand high temperatures, making them ideal for use in high-pressure ball mills.

3. How are grinding steel balls made?

Grinding steel balls are typically produced by melting steel billets or rods into a hollow ingot. The ingots are then bored and sintered at high temperatures to create the balls. There are also automated methods of manufacturing grinding steel balls, but these may be more complex and expensive than traditional methods.

4. Can grinding steel balls be used in other industries besides ball milling?

Yes, grinding steel balls can be used in a variety of industries beyond ball milling. They are commonly used in the production of iron and steel, as well as in metal recycling and other applications where high crushing efficiency is required.

5. Are there any alternative materials to grinding steel balls that can be used in ball milling?

While grinding steel balls are the most common material used in ball milling, other materials such as carbon balls, ceramic balls, and natural minerals may also be used depending on the specific application. However, these materials may have lower crushing efficiency and longer service lives compared to grinding steel balls.

(Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Ball mill spare parts Ball mill ring gear and gears Ball mill Gears

Factory Spare Parts For Mining Crusher Precision Ball Mill Liner Impact Crusher Hammer Crusher For Stone Crushing

High manganese casting ball mill parts mill impact liner plate and blow bar

Wear resistant non-standard Heavy Machinery Ball Mill Parts large Casting Liner Plate

High Capacity ball mill machine dry wet ball stone grinding gold ball mill catalytic converter parts and accessories