PRODUCT PARAMETERS

Description

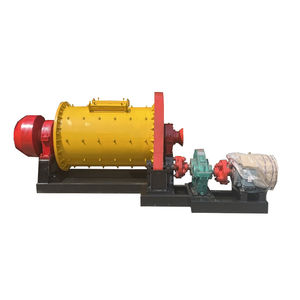

Brief introduction of Custom FE1830*3600mm Ball Mill for 5.8-25TPH Dry Wet Overflow Grinding Equipment for Quartz,Limestone,Ore,Cement etc

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Custom FE1830*3600mm Ball Mill for 5.8-25TPH Dry Wet Overflow Grinding Equipment for Quartz,Limestone,Ore,Cement etc refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Custom FE1830*3600mm Ball Mill for 5.8-25TPH Dry Wet Overflow Grinding Equipment for Quartz,Limestone,Ore,Cement etc

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Custom FE1830*3600mm Ball Mill for 5.8-25TPH Dry Wet Overflow Grinding Equipment for Quartz,Limestone,Ore,Cement etc)

Specification of Custom FE1830*3600mm Ball Mill for 5.8-25TPH Dry Wet Overflow Grinding Equipment for Quartz,Limestone,Ore,Cement etc

The Custom-made FE1830 × 3600mm Ball Mill is a flexible grinding remedy created for dry and damp overflow processing, supplying a throughput of 5.8– 25 TPH depending upon product and functional problems. Engineered for sturdiness and performance, it manages products such as quartz, sedimentary rock, ore, cement, and other minerals, satisfying industries like mining, building and construction, and chemical processing. Its robust design ensures trusted performance in both constant and batch operations.

Trick specs consist of a drum diameter of 1800mm (FE1830) and size of 3600mm, constructed from state-of-the-art steel with reinforced liners to stand up to unpleasant products. The mill runs at a rotational rate of 21– 23 RPM, powered by an 18.5– 22 kW electric motor coupled with a gear-and-pinion drive system for smooth torque transmission. Grinding media choices consist of steel, ceramic, or chrome alloy spheres, flexible in dimension (25– 150mm) to maximize particle dimension circulation. The overflow discharge system makes sure constant product fineness by allowing ground material to leave when it reaches the desired size, stopping over-grinding.

Customization options consist of tailored linings (rubber, manganese, or polyurethane) to minimize wear, option of bearing types (trunnion or gliding), and variable-speed drives for process control. The mill supports wet grinding with slurry feed or completely dry grinding with airflow, adapting to diverse functional needs. Safety and security features consist of overload defense, emergency braking, and temperature sensing units to avoid mechanical failings.

Applications extend great grinding of cement clinker, mineral ore beneficiation, sedimentary rock slurry prep work, and quartz handling for commercial uses. Its energy-efficient style lessens power usage, while the sealed framework lowers dust discharges, abiding by ecological criteria. Installation and maintenance are streamlined with accessible elements and optional automatic lubrication systems.

The FE1830 × 3600mm Sphere Mill is constructed to ISO standards, providing lengthy service life with marginal downtime. Extensive assistance consists of technological consultation, installation support, and after-sales maintenance. Ideal for medium-to-large-scale procedures, this mill balances precision, versatility, and cost-effectiveness for requiring grinding jobs.

(Custom FE1830*3600mm Ball Mill for 5.8-25TPH Dry Wet Overflow Grinding Equipment for Quartz,Limestone,Ore,Cement etc)

Applications of Custom FE1830*3600mm Ball Mill for 5.8-25TPH Dry Wet Overflow Grinding Equipment for Quartz,Limestone,Ore,Cement etc

The Customized FE1830 * 3600mm Round Mill is a flexible grinding service made for dry and wet overflow handling throughout markets. With a throughput ability of 5.8– 25 lots per hour (TPH), this durable equipment efficiently deals with materials like quartz, limestone, ore, concrete, and a lot more, delivering regular fragment size distribution for diverse applications. Its 1830mm size and 3600mm round chamber, built from state-of-the-art steel, make certain toughness and resistance to put on, even under heavy-duty operations. The round mill’s overflow discharge device enables continual procedure by immediately launching ground product once it gets to the wanted fineness, making it perfect for both open and closed-circuit grinding systems.

In quartz handling, the mill creates finely ground silica for glass, porcelains, and electronics, ensuring high purity and uniformity. For limestone, it supports the manufacturing of building materials like concrete and accumulations, optimizing bit dimension for improved sensitivity in commercial procedures. In mining, the mill efficiently grinds ores to free beneficial minerals, enhancing recuperation prices in downstream removal. Cement manufacturers gain from its ability to homogenize clinker and additives, making sure product consistency and stamina.

The FE1830 * 3600mm Sphere Mill suits both completely dry and damp grinding. Wet processing leverages water to minimize heat and achieve ultra-fine results, while dry grinding matches moisture-sensitive products, decreasing post-processing actions. Its energy-efficient motor decreases functional expenses, and the personalized liners/grinding media allow adaptation to particular material hardness or fineness requirements. Low upkeep style, consisting of easy-access parts and automated lubrication, makes sure marginal downtime.

Suitable for tiny to large operations, this round mill integrates integrity, flexibility, and precision. Whether refining quartz for high-tech applications or grinding sedimentary rock for facilities projects, it delivers optimum performance. Adjustable alternatives, such as flexible speed controls or specialized coverings, cater to special operational requirements. Backed by comprehensive technical assistance and crafted for durability, the FE1830 * 3600mm Ball Mill is a cost-effective, high-yield option for commercial grinding challenges.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Custom FE1830*3600mm Ball Mill for 5.8-25TPH Dry Wet Overflow Grinding Equipment for Quartz,Limestone,Ore,Cement etc

**What materials can the Custom FE1830*3600mm Ball Mill process?**

The ball mill is designed for grinding a wide range of materials, including quartz, limestone, ore, cement, clinker, slag, and non-ferrous metals. It efficiently handles both dry and wet processing, making it versatile for industries like mining, construction, and cement production.

**What is the production capacity of this ball mill?**

The throughput ranges from 5.8 to 25 tons per hour (TPH), depending on material hardness, feed size, and required output fineness. Wet grinding typically achieves higher capacity due to easier material flow, while dry grinding offers flexibility for moisture-sensitive applications.

**How does the overflow design benefit grinding operations?**

The overflow discharge mechanism allows finer particles to exit the mill continuously, preventing over-grinding and ensuring consistent product quality. This design is ideal for materials requiring uniform particle size distribution, such as quartz and limestone, in closed-circuit grinding systems.

**Is the ball mill suitable for both dry and wet grinding?**

Yes. The mill supports dry grinding for moisture-sensitive materials (e.g., cement) and wet grinding for ores and minerals requiring slurry formation. Users can switch modes by adjusting the material-to-water ratio and discharge configurations.

**What maintenance is required for long-term operation?**

Regular lubrication of bearings and gears, inspection of liners and grinding media for wear, and monitoring of motor performance are essential. The robust design minimizes downtime, but scheduled maintenance every 6–12 months ensures optimal efficiency and lifespan. High-quality alloy steel components enhance durability under heavy loads.

**How energy-efficient is this ball mill?**

It incorporates an optimized drive system and low-friction bearings to reduce power consumption. Energy usage varies with material hardness and grinding mode, but the mill meets industry standards for efficiency, balancing output and operational costs.

(Custom FE1830*3600mm Ball Mill for 5.8-25TPH Dry Wet Overflow Grinding Equipment for Quartz,Limestone,Ore,Cement etc)

REQUEST A QUOTE

RELATED PRODUCTS

Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone

Customized Heavy Duty Cnc Lathe Machining Casting Cement Cap Ball Mill Heads Steel End Cover

Customized Various Sizes Rotary Kiln Spare Parts Cement Ball Mill Drive Large Casting Gears