PRODUCT PARAMETERS

Description

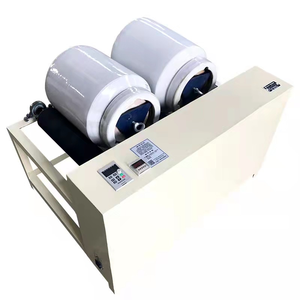

Brief introduction of Effective Large Capacity Ball.Mill Ball Mill For Mining

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Effective Large Capacity Ball.Mill Ball Mill For Mining refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Effective Large Capacity Ball.Mill Ball Mill For Mining

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Effective Large Capacity Ball.Mill Ball Mill For Mining)

Specification of Effective Large Capacity Ball.Mill Ball Mill For Mining

The Effective Big Capacity Round Mill for Mining is developed to meet the extensive needs of mineral processing operations, offering remarkable grinding performance, longevity, and efficiency. Engineered for high-capacity applications, this sphere mill is suitable for grinding ores such as gold, copper, iron, and various other metal or non-metallic materials. Its robust building ensures trusted operation in extreme mining settings.

** Key Requirements: **.

– ** Capability **: The mill takes care of large handling with a throughput variety of 5 to 150 bunches per hour, depending upon design and ore attributes.

– ** Source of power **: Furnished with high-torque electric motors (200 kW to 4500 kW) for regular power distribution, making certain optimum grinding effectiveness.

– ** Drum Dimensions **: Offered in numerous sizes, with drum sizes approximately 4.5 meters and lengths as much as 12 meters, supplying sufficient grinding volume.

– ** Material Building **: The drum and essential parts are made from top-quality steel, reinforced with wear-resistant linings (rubber or manganese) to extend service life.

– ** Grinding Media **: Suitable with steel rounds varying from 25 mm to 150 mm in size, guaranteeing accurate bit size decrease.

– ** Loading Capacity **: Created to stand up to 30– 40% of its quantity in grinding media and product for balanced procedure.

– ** Rotational Rate **: Flexible rate control (70– 80% of essential speed) to maximize grinding activity for various ore kinds.

** Functional Functions: **.

– Advanced birthing systems minimize friction and energy usage.

– Automated lubrication systems make sure minimal downtime.

– Integrated safety devices, including temperature level sensors and overload security, protect equipment and drivers.

– Modular design simplifies maintenance and element substitute.

** Applications **: Appropriate for both damp and dry grinding procedures in open or shut circuits. It successfully refines raw ore into great powders for succeeding extraction stages.

** Power Performance **: Optimized style decreases power usage per ton of processed product, decreasing functional prices.

** Compliance **: Manufactured to satisfy global requirements (ISO, CE) for quality and safety and security.

This ball mill combines high throughput, reliability, and reduced maintenance, making it a cost-efficient service for large-scale mining operations seeking consistent grinding efficiency.

(Effective Large Capacity Ball.Mill Ball Mill For Mining)

Applications of Effective Large Capacity Ball.Mill Ball Mill For Mining

The Efficient Huge Capacity Round Mill is a durable and functional grinding option developed for high-performance mineral handling in the mining market. Engineered to manage requiring ore grinding tasks, this round mill is perfect for processing a variety of materials, consisting of gold, copper, iron, zinc, and uncommon earth minerals. Its large capability layout makes certain effective handling of bulk products, making it suitable for both open-pit and below ground mining operations. The ball mill operates by rotating a round chamber full of grinding media, such as steel or ceramic rounds, which crush and grind raw ore right into great particles, allowing efficient mineral removal. This process is critical in preparing ores for subsequent phases like flotation protection, leaching, or smelting. Trick applications include key and additional grinding of metallic ores, grinding of industrial minerals like limestone and quartz, and processing tailings for source recovery. Built with wear-resistant linings and sturdy components, it withstands unpleasant settings, reducing maintenance downtime. The enhanced energy-efficient design decreases power intake while maintaining high throughput, equating to cost financial savings for mining procedures. Its scalability suits small to massive jobs, and progressed control systems guarantee constant particle size circulation for optimum healing prices. The round mill’s versatility enables customization with various linings, drive systems, and grinding media to suit certain ore characteristics and operational demands. With a focus on dependability and productivity, this large-capacity round mill is a foundation of modern mining operations, supplying improved grinding efficiency, reduced functional prices, and long-term longevity. Whether utilized in rare-earth element removal or base metal processing, it gives a reputable remedy for optimizing mineral yield and sustaining high production levels in difficult mining environments.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Effective Large Capacity Ball.Mill Ball Mill For Mining

**1. What is the primary purpose of a large-capacity ball mill in mining?**

A large-capacity ball mill is designed to grind mined ore into fine particles, enabling efficient extraction of valuable minerals. It uses rotating cylinders filled with steel balls to crush and grind materials, making it ideal for processing high volumes of hard or abrasive ores in mining operations. Its scale ensures consistent output for downstream processes like flotation or leaching.

**2. What is the maximum processing capacity of this ball mill?**

This ball mill handles up to 100 tons per hour, depending on material hardness and grind size requirements. Its large drum diameter and extended length optimize grinding efficiency, while robust construction supports continuous operation in demanding mining environments. Customizable configurations allow capacity adjustments based on specific project needs.

**3. Which materials can this ball mill effectively process?**

It processes a wide range of materials, including gold, copper, iron ore, limestone, and quartz. The hardened steel or rubber liners and high-quality grinding media ensure durability against abrasive substances. It’s also suitable for wet or dry grinding, adapting to diverse mineral processing workflows.

**4. How does this ball mill reduce energy consumption?**

Advanced drive systems, such as variable frequency motors and optimized rotational speeds, minimize energy use. Efficient load distribution and low-friction bearings further cut power demands. These features lower operational costs while maintaining high throughput, aligning with sustainable mining practices.

**5. What maintenance practices ensure long-term reliability?**

Routine inspections of liners, bearings, and gears prevent unexpected downtime. Automated lubrication systems reduce wear, and easily replaceable parts simplify repairs. The mill’s design includes accessible inspection points, and manufacturers often provide remote monitoring support to predict maintenance needs, ensuring longevity in harsh mining conditions.

(Effective Large Capacity Ball.Mill Ball Mill For Mining)

REQUEST A QUOTE

RELATED PRODUCTS

Gear Shaft For Ball Mill Spline Gear Shaft Mining Spare Parts Gear Shaft For Gearbox

Customized Heavy Duty Cnc Lathe Machining Casting Ball Mill Spare Parts Ball Mill End Cover

Mineral Ball Mill Spare Parts Gold Grinder Ball Mills Machine Metal Ball Mill for Gold Mining

Ball Mill Working Principle, Milling Machine Tube, Overflow Ball Mill

Steel Gold Ore Rock Mining Ball Mill Machine