PRODUCT PARAMETERS

Description

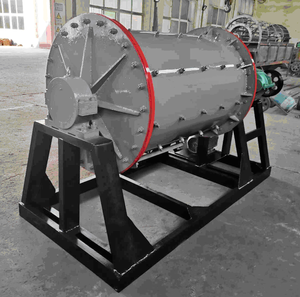

Brief introduction of Factory direct s all kinds of Ball Mill 24004500 smooth operation dry wet grinding

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Factory direct s all kinds of Ball Mill 24004500 smooth operation dry wet grinding refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Factory direct s all kinds of Ball Mill 24004500 smooth operation dry wet grinding

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Factory direct s all kinds of Ball Mill 24004500 smooth operation dry wet grinding)

Specification of Factory direct s all kinds of Ball Mill 24004500 smooth operation dry wet grinding

The Manufacturing Facility Direct Round Mill 2400 4500 is created for trustworthy efficiency in completely dry and damp grinding applications. This design includes a drum diameter of 2.4 meters and a length of 4.5 meters, constructed with top notch steel for resilience. The durable structure makes certain long-term usage even under heavy workloads. It operates efficiently because of a well balanced rotating mechanism and precision-engineered parts, decreasing resonance and noise throughout grinding.

This round mill supports both completely dry and damp handling. Dry grinding is optimal for materials like concrete clinker and ceramics. Damp grinding handles ores, chemicals, and various other slurries effectively. The dual-function layout offers versatility across markets, including mining, construction, and metallurgy.

The motor makes use of a durable electric drive system, supplying regular power for stable operation. Gear transmission makes sure accurate control over rotation rate, adjusting to various material needs. The lining plates inside the drum are constructed from wear-resistant alloy, minimizing wear and extending service life.

Factory straight sales cut out middlemen, supplying expense financial savings without endangering quality. Each system goes through rigorous testing before distribution, assuring reputable efficiency. The style focuses on power effectiveness, lowering power intake contrasted to typical versions. Maintenance is streamlined with accessible components and an easy to use structure.

The 2400 4500 ball mill processes big quantities successfully, with a capacity tailored to industrial-scale procedures. Security functions include overload security and emergency situation quit functions, making certain driver safety and security. Personalization alternatives are available for particular requirements, such as flexible rate setups or additional safety and security systems.

This version fits companies seeking an equilibrium of performance and affordability. Its flexibility across grinding methods makes it a practical option for varied product handling tasks. The mix of smooth operation, resilient building and construction, and affordable prices settings it as an affordable option for sturdy grinding demands.

(Factory direct s all kinds of Ball Mill 24004500 smooth operation dry wet grinding)

Applications of Factory direct s all kinds of Ball Mill 24004500 smooth operation dry wet grinding

The factory direct sale Sphere Mill 2400 4500 is made for heavy-duty grinding tasks across markets. It handles dry and damp materials effectively. This maker fits mining, cement, ceramics, and chemical industries. Its huge cylinder dimension permits high-capacity processing. The 2400mm size and 4500mm length develop enough room for grinding media and raw materials. This arrangement makes sure consistent bit size decrease.

The ball mill runs efficiently because of a balanced rotating mechanism. Sturdy bearings and a strong frame decrease vibrations. This reduces wear on elements. The electric motor supplies dependable power for continuous procedure. Users readjust turning speed to match product demands. Wet grinding blends fluids with resources for slurry processing. Dry grinding takes care of moisture-sensitive substances. Both methods generate fine powders for commercial usage.

Durable products guarantee lengthy service life. The internal lining uses wear-resistant alloys. Steel grinding rounds crush products efficiently. The style prevents contamination during processing. Secured compartments keep external fragments out. This is essential for purity in chemical and food-related applications. Maintenance is straightforward. Gain access to factors allow quick assessment of inner parts. Substitute of linings or balls needs minimal downtime.

Personalization alternatives meet certain demands. Clients pick lining products based on abrasion resistance or chemical compatibility. Motor power can be scaled for higher workloads. The maker incorporates with existing assembly line. Automation functions enable remote surveillance. Sensing units track temperature level and stress to stop overloads.

Factory direct rates cuts costs by getting rid of intermediaries. Buyers obtain high quality tools at competitive rates. Technical support is available for setup and troubleshooting. Spare parts are provided immediately to decrease operational hold-ups.

This ball mill fits large-scale and specific tasks. Mining operations grind ores for mineral extraction. Cement plants grate clinker to produce fine concrete. Ceramic manufacturing facilities mix glazes and raw clay. Chemical markets process powders for pharmaceuticals or fertilizers. The maker’s adaptability makes it a core property in material handling. Reliability and efficiency make sure constant output for varied industrial needs.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Factory direct s all kinds of Ball Mill 24004500 smooth operation dry wet grinding

What is a ball mill used for? A ball mill grinds materials into fine powder. It works for both dry and wet processes. Industries like cement, mining, and ceramics rely on it. The 24004500 model handles large-scale operations efficiently.

How does the 24004500 ball mill ensure smooth operation? The design includes a robust motor and balanced rotating drum. High-quality steel liners reduce wear. Precision bearings minimize vibration. These features keep the machine stable during long runs. Maintenance needs drop.

Can this ball mill handle both dry and wet grinding? Yes. The 24004500 model supports both methods. Wet grinding mixes materials with water or liquids. Dry grinding processes materials without added moisture. The drum’s structure stays durable in either condition. Switch modes based on your material type.

What materials can this ball mill grind? It processes metals, ores, cement, and ceramics. Hard or soft materials work. Particle size adjusts by changing grinding time or speed. The machine’s size suits heavy-duty tasks. Check material compatibility with the supplier first.

Why choose factory-direct ball mills? Factory-direct cuts middlemen costs. Buyers get lower prices. Quality control is strict during production. Technical support comes directly from experts. Delivery times shorten. Custom requests get handled faster.

The 24004500 ball mill uses a motor with high torque. Power consumption stays low. The drum rotates steadily for even grinding. Liners protect the drum from damage. Wear-resistant materials extend the machine’s life.

Wet grinding prevents dust and suits heat-sensitive materials. Dry grinding saves time on drying steps. Both methods produce consistent results. Choose based on your project’s needs.

Steel balls inside the drum crush materials. Ball size and material affect grinding efficiency. Regular checks ensure optimal performance. Replace worn balls promptly. Clean the drum to avoid cross-contamination.

This model suits large factories and mining sites. Installation requires a solid foundation. Operators need basic training. Safety protocols prevent accidents. Follow the manual for best results.

Spare parts are available directly from the factory. Genuine parts ensure compatibility. Stock essential components to avoid downtime. Contact support for troubleshooting help. Service teams respond quickly.

Energy efficiency reduces operating costs. The design minimizes heat generation. Noise levels stay within safe limits. These factors make the 24004500 a practical investment. Output quality meets industry standards.

(Factory direct s all kinds of Ball Mill 24004500 smooth operation dry wet grinding)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Forged Steel Balls and liners For Ball Mill, Attrition Mill

Cement plant ball mill pinion /pinion gear for ball mill