PRODUCT PARAMETERS

Description

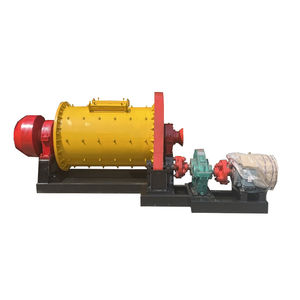

Brief introduction of Factory Direct Supply High Quality ball mill with rubber liner ball mill

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Factory Direct Supply High Quality ball mill with rubber liner ball mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Factory Direct Supply High Quality ball mill with rubber liner ball mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Factory Direct Supply High Quality ball mill with rubber liner ball mill)

Specification of Factory Direct Supply High Quality ball mill with rubber liner ball mill

The Manufacturing Facility Straight Supply High Quality Ball Mill with Rubber Lining is a robust and effective grinding remedy designed for industrial applications requiring longevity, decreased upkeep, and enhanced efficiency. This round mill is engineered with a high-quality rubber lining, providing remarkable resistance to put on, deterioration, and impact compared to standard steel linings. It is perfect for grinding rough products in mining, concrete, ceramics, and chemical industries.

** Specifications: **.

– ** Capacity: ** Available in multiple dimensions, ranging from 0.5 TPH (tonnes per hour) to 150 TPH, accommodating small-scale procedures to big industrial arrangements.

– ** Motor Power: ** Powered by energy-efficient electrical motors from 15 kW to 4500 kW, making sure ideal efficiency with reduced power usage.

– ** Turning Rate: ** Flexible rotation speed between 18-38 RPM, customizable to match material hardness and preferred fineness.

– ** Lining Material: ** High-grade rubber linings (25-50 mm thickness) with outstanding abrasion resistance, minimizing downtime for replacements.

– ** Drum Measurements: ** Cylinder diameters from 900 mm to 4500 mm, with lengths ranging 1800 mm and 8000 mm.

– ** Grinding Media: ** Suitable with steel, ceramic, or rubber balls (20-150 mm diameter) for functional grinding applications.

– ** Feed & Discharge: ** Created for both overflow and grate discharge setups, sustaining dry or wet grinding processes.

– ** Product Handling: ** Processes materials including ores, concrete clinker, silicates, plant foods, and non-ferrous steels.

** Trick Features: **.

– ** Noise Decrease: ** Rubber linings moisten operational noise, improving work environment safety and conformity.

– ** Expanded Life-span: ** The rubber lining minimizes wear on the mill’s internal framework, increasing life span compared to steel-lined mills.

– ** Corrosion Resistance: ** Ideal for wet grinding and acidic/alkaline environments.

– ** Easy Maintenance: ** Lightweight rubber liners streamline installation and substitute, reducing labor prices.

– ** Thermal Insulation: ** Rubber works as a thermal barrier, maintaining secure temperatures during extended procedures.

** Applications: **.

Ideal for key and additional grinding phases in mineral handling, cement manufacturing, pigment production, and coal pulverization.

** Customization: **.

Available with tailored specs, consisting of motor type, liner density, drum finishes, and automation controls (e.g., PLC systems).

** Quality control: **.

Manufactured under ISO 9001 requirements, with rigorous testing for vibration, tons ability, and equilibrium.

** Factory Straight Benefits: **.

Remove middlemen markups, guaranteeing competitive prices, dependable technical support, and a 12-month guarantee. The ball mill ships pre-assembled or modular for simple installment, backed by international after-sales service.

(Factory Direct Supply High Quality ball mill with rubber liner ball mill)

Applications of Factory Direct Supply High Quality ball mill with rubber liner ball mill

The factory direct supply premium sphere mill with a rubber liner is a functional and sturdy grinding remedy created for sectors calling for reliable product processing. The rubber lining improves the mill’s efficiency by offering exceptional wear resistance, sound reduction, and prolonged operational lifespan compared to traditional steel liners. Its applications cover several sectors, including mining, chemical processing, concrete manufacturing, and recycling, making it an essential asset for services prioritizing cost-effectiveness and integrity.

In ** mining and mineral handling **, the rubber-lined sphere mill is suitable for grinding ores, such as gold, copper, and iron, into fine powders. The rubber lining minimizes steel contamination, making sure higher pureness in extracted products. Its shock-absorbing buildings lower energy usage and safeguard the mill’s framework from abrasive wear, also when refining difficult or crude minerals.

The ** chemical industry ** benefits from the rubber lining’s rust resistance when handling destructive materials or acidic slurries. It protects against chain reactions in between the grinding media and products, maintaining item stability. In addition, the liner’s flexibility lowers splitting under thermal anxiety, making sure constant efficiency in high-temperature environments.

In ** cement and building product manufacturing **, the round mill effectively grinds resources like limestone, clinker, and gypsum. The rubber lining’s durability withstands continuous unpleasant action, lowering maintenance expenses and downtime. Its noise-dampening high qualities likewise create a more secure workplace by lowering operational decibel levels.

For ** reusing and waste management **, this round mill processes industrial by-products, such as slag or digital waste, right into multiple-use products. The rubber lining’s durability ensures longevity when managing heterogeneous or hard-to-grind substances. It additionally avoids sparking, a vital safety and security feature when refining combustible products.

The ** pharmaceutical and food markets ** leverage the rubber-lined ball mill for grinding delicate products without contamination. The non-reactive rubber surface area makes certain hygienic handling, meeting stringent governing requirements for item safety and security.

Key advantages of factory-direct supply include price savings, quality assurance, and personalization alternatives. The rubber lining’s layout can be tailored to details grinding requirements, such as fragment size or throughput capability. Incorporated with energy-efficient operation and reduced upkeep needs, this round mill supplies long-term worth for markets looking for trustworthy, high-performance grinding services. Investing in a rubber-lined sphere mill makes sure boosted performance, reduced functional costs, and a lasting approach to commercial material handling.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Factory Direct Supply High Quality ball mill with rubber liner ball mill

What is a rubber liner ball mill, and how does it differ from traditional ball mills? A rubber liner ball mill is a grinding machine equipped with rubber liners instead of metal ones. The rubber lining reduces noise, minimizes wear and tear on the mill’s interior, and offers better resistance to corrosion. Unlike traditional steel liners, rubber liners absorb impacts more effectively, extending the equipment’s lifespan and lowering maintenance costs.

Why choose a factory-direct rubber liner ball mill? Purchasing directly from the manufacturer eliminates middlemen, ensuring competitive pricing and quality control. Factory-direct suppliers often provide customized solutions, strict adherence to industry standards, and after-sales support. This guarantees you receive a high-quality, durable ball mill tailored to your operational needs without unnecessary markups.

What industries benefit most from rubber liner ball mills? Rubber liner ball mills are ideal for mining, cement production, ceramics, and chemical processing. They excel in wet or dry grinding of ores, minerals, and other materials. The rubber lining’s anti-corrosive properties make them suitable for abrasive or chemically reactive substances, ensuring consistent performance in harsh environments.

How long do rubber liners last compared to steel liners? Rubber liners typically outlast steel liners by 2–3 times, depending on usage conditions. Their elasticity reduces cracking under impact, and they resist chemical degradation. While initial costs might be higher, the extended lifespan and reduced downtime for replacements result in significant long-term savings.

Can the rubber liner be replaced easily? Yes. Rubber liners are designed for straightforward replacement, often requiring fewer tools and less labor than metal liners. Many manufacturers offer modular or segmented liner designs, allowing partial replacements without dismantling the entire mill. This minimizes operational interruptions and maintenance costs.

What maintenance practices ensure optimal performance? Regularly inspect liners for wear, clean the mill to prevent material buildup, and ensure proper lubrication of moving parts. Avoid overloading the mill, and use grinding media of appropriate size and density. Following the manufacturer’s guidelines for operational parameters (e.g., rotation speed, material load) maximizes efficiency and liner longevity.

(Factory Direct Supply High Quality ball mill with rubber liner ball mill)

REQUEST A QUOTE

RELATED PRODUCTS

Ball Mill mining Equipment Accessories Hollow Shaft ball Mill Hollow Shaft For Material Feeding And Discharging

Mining Equipment Parts Ball Mill Machine Mining Equipment Sand Making Machine Ball Grinding Mill Liner Spare Parts

Cast White Iron AS 2027 CrMo 15 Grinding Ball Mill liner Wear Plate

Mining ball mill chromium molybdenum alloy liner vulnerable parts, large cast steel spare parts, new product mill liner

Wet Small Ball Mill Grinding Machine Spare Parts for in Zimbabwe