PRODUCT PARAMETERS

Description

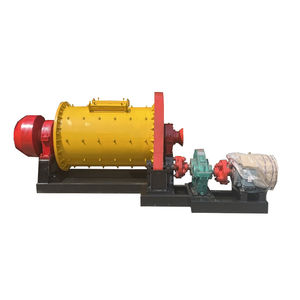

Brief introduction of Factory of Small Ball Mill 900×1800 For 1 Ton Gold Mine Ball Mill Parts

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Factory of Small Ball Mill 900×1800 For 1 Ton Gold Mine Ball Mill Parts refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Factory of Small Ball Mill 900×1800 For 1 Ton Gold Mine Ball Mill Parts

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Factory of Small Ball Mill 900×1800 For 1 Ton Gold Mine Ball Mill Parts)

Specification of Factory of Small Ball Mill 900×1800 For 1 Ton Gold Mine Ball Mill Parts

The specification of the factory of small ball mill 900×1800 for 1 ton gold mine ball mill parts can vary depending on the specific needs and requirements of the mining operation. However, some common factors that may be included in these specifications include the size and shape of the mill balls, their material composition, the type and design of the grinding chamber, and the weight capacity of the machine.

In general, the specifications for a small ball mill will include details such as the maximum operating speed, the minimum feed size, the maximum mill discharge size, and the number of balls used in the mill. The ball mill itself will typically have a size range from approximately 2mm to 5mm, depending on the desired particle size and throughput of the material being processed. The material to be ground will be specified based on the intended application and the properties of the material being crushed.

The design and construction of the grinding chamber in the ball mill is critical to its performance and reliability. The chamber should be designed to minimize wear and tear on the mill balls, while maximizing the efficiency of grinding operations. This may involve using materials with high strength-to-weight ratios or incorporating advanced design features such as ball attrition reduction systems.

The weight capacity of the ball mill is another important factor to consider when specifying its specifications. A larger ball mill may be more suitable for large-scale operations, but it may also require additional maintenance and setup costs. Conversely, a smaller ball mill may be easier to maintain and operate, but it may not be able to process very dense materials or meet production demands at lower load rates.

Overall, the specification of the factory of small ball mill 900×1800 for 1 ton gold mine ball mill parts will depend on a variety of factors, including the specific needs and requirements of the mining operation. However, by carefully considering these factors and selecting appropriate specifications, manufacturers can help ensure that their machines are well-designed and reliable for long-term use.

(Factory of Small Ball Mill 900×1800 For 1 Ton Gold Mine Ball Mill Parts)

Applications of Factory of Small Ball Mill 900×1800 For 1 Ton Gold Mine Ball Mill Parts

Factory of Small Ball Mill 900×1800 is a manufacturer that specializes in the production and sale of ball mill parts for gold mines, including small ball mills with diameters of 900mm x 1800mm. These mills are designed to grind all types of ores and minerals, from quartz to precious metals such as gold and silver.

One of the key benefits of using a small ball mill like this one is its efficiency. The large size of the mill chamber allows it to grind particles of various sizes, which can reduce the amount of material needed for processing and increase overall throughput. This means that less time is required to process ore, which can lead to faster recoveries and higher profits.

In addition to their efficiency, small ball mills also offer some other advantages over larger mills. They are generally more cost-effective, as they require less maintenance and operating time than larger models. They are also easier to transport and store, as they can be transported on flat surfaces rather than being loaded onto barge or truck decks.

When selecting ball mill parts for your gold mine, it’s important to consider factors such as the type of ore being processed, the desired grind size, and the budget for equipment investment. With the right equipment, you can ensure that you’re getting the most out of your investment and maximizing your profits.

Factory of Small Ball Mill 900×1800 is committed to providing high-quality and reliable ball mill parts for our customers. We understand the importance of efficient and effective mining operations, and we strive to provide solutions that meet these needs.

If you’re looking for ball mill parts for your gold mine, contact us today to learn more about our products and services. We’d be happy to discuss your specific requirements and provide recommendations for the best solution for your needs.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Factory of Small Ball Mill 900×1800 For 1 Ton Gold Mine Ball Mill Parts

Q: What is the output size of a small ball mill for 1 ton gold mine?

A: The output size of a small ball mill for 1 ton gold mine can vary depending on several factors such as the grinding media used, operating conditions, and the specific design of the mill. However, in general, a small ball mill with a diameter of 900mm to 1800mm and an attrition ratio of 60% to 80% will be able to grind a sample size of up to 1 ton of gold ore per hour.

Q: Can I use small ball mill for different types of minerals other than gold?

A: Yes, a small ball mill can be used for different types of minerals other than gold by adjusting the grinding media type and throughput. For example, a ball mill can be used for grinding coal, iron ore, and phosphate rock to recover these minerals from ore.

Q: How does the grinding process work in a small ball mill?

A: The grinding process in a small ball mill works by using high-speed rotation of the balls or disks inside the mill. As the balls or disks are turned, they collide with the ore particles, causing them to break down into smaller pieces. The resulting material can then be sieved and removed from the mill.

Q: Are there any safety precautions that need to be taken when working with a small ball mill?

A: Yes, safety is a critical consideration when working with a small ball mill. To minimize the risk of injury, workers should wear appropriate personal protective equipment (PPE) such as safety glasses, hearing protection, and steel-toed boots. Additionally, proper maintenance and cleaning of the mill’s components and machinery is essential to ensure optimal performance and prevent accidents.

Q: Can I use small ball mill for both wet and dry operations?

A: No, a small ball mill cannot be used for both wet and dry operations. A wet ball mill is typically designed to operate in conjunction with a classifier to separate gold ore from gangue, while a dry ball mill operates without this separation step.

Q: What are some common issues that can arise when operating a small ball mill?

A: Some common issues that can arise when operating a small ball mill include overheating, clogging of the grinding media, damage to the mill’s components, and poor accuracy of the mining operation. To address these issues, regular and cleaning of the mill’s components, as well as proper operator training, are necessary.

(Factory of Small Ball Mill 900×1800 For 1 Ton Gold Mine Ball Mill Parts)

REQUEST A QUOTE

RELATED PRODUCTS

High Chrome manganese Alloy cement quartz copper and gold ore ball mill liner wear plate spare parts

Superir Hot Low Ball Mill Grinding Machine With Lower Starting Power

Overflow ball mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement

OEM customize cast alloy ball mill liners wear resistant lining plate spare parts

Casting Girth Gears Rotary Kiln And Cement Ball Mill Spare Parts Large Steel Spur Gear Wheel and Ring Gear