PRODUCT PARAMETERS

Description

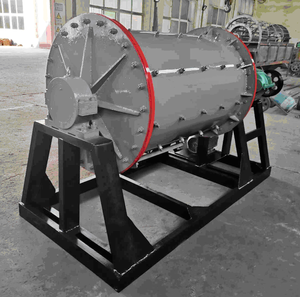

Brief introduction of Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding

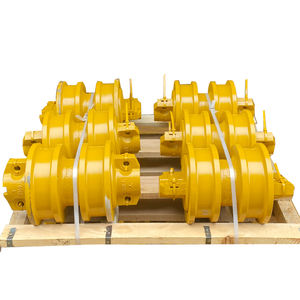

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding)

Specification of Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding

Gold ore lead zinc copper mining stone mini steel coal steel used wet ball mill and dry ball mill for mining grinding.

Introduction:

Ball mills are widely used in the mining industry for grinding and processing of minerals such as gold, lead zinc, copper, etc. These machines are designed to grind materials into smaller sizes without compromising their quality or purity. The choice of ball mill type depends on various factors such as material properties, operating conditions, budget, and the required grinding size. This article provides information about specifications of different types of ball mills for gold ore lead zinc copper mining, stone, mini steel, coal, and steel grinding.

Ball Mill Type:

1. Wet Ball Mill: A wet ball mill consists of two or more chambers where water is poured into the grinding chamber. The water helps to break up the mineral particles, making them easier to be ground. The balls inside the mill are wet and milled with water, which leads to a higher grinding efficiency than dry ball mills.

2. Dry Ball Mill: A dry ball mill consists of one chamber where the grinding media is solid and dry. The balls inside the mill are dry and milled using electricity, resulting in a lower grinding efficiency than wet ball mills. However, dry ball mills have higher energy consumption compared to wet ball mills.

Characteristics:

1. Material Properties: The material properties of the mine being processed should be considered when choosing a ball mill type. For example, materials that are too hard may require a wet ball mill, while materials that are too soft may require a dry ball mill.

2. Operating Conditions: The operating conditions of the ball mill, including the speed, feed size, and operating pressure, must be carefully optimized to ensure optimal grinding efficiency.

3. Budget: The cost of ball mill installation, maintenance, and repair should also be taken into account when choosing a ball mill type.

Applications:

Ball mills can be used for grinding and processing of minerals in various industries such as mining, power plants, and food processing. They are particularly useful for grinding coal, gold, and other minerals that are difficult to process using traditional grinding methods.

Conclusion:

Ball mills are an essential equipment for mining grinding, and selecting the right type of ball mill based on the requirements of the mine being processed can significantly improve grinding efficiency and reduce costs. Proper selection and operation of ball mills can ensure the safe and efficient processing of minerals for maximum production.

(Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding)

Applications of Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding

Gold ore, lead zinc, copper mining is an important sector in the mining industry worldwide. These minerals are essential raw materials for the production of various products such as construction materials, electrical components, and other industrial applications.

Wet ball mills are commonly used in gold ore and lead zinc mining to crush and grind the ore into fine particles. The wet ball mill operates on the principle of force-matter conversion, where energy (in the form of kinetic energy) is transferred from the material to its constituent parts. This causes the material to be crushed and ground into smaller pieces, which can then be separated from the rest of the ore.

Dry ball mills, on the other hand, operate on the principles of temperature and pressure. They use hot water or steam to rotate a steel balls that inside the mill are designed to reduce the size of the ore particles. As the moisture in the ore is removed, it becomes more susceptible to being crushed and ground by the rotating balls. Dry ball mills are often used for the processing of hard rock ore, such as those found in the mountains.

In addition to their use in gold ore and lead zinc mining, wet and dry ball mills are also used in coal mining to extract valuable minerals such as coal fines and gangue. They can also be used in steel manufacturing to produce high-quality steel bars and plates.

Overall, wet and dry ball mills are highly versatile machines that play an important role in the extraction and processing of minerals from their respective mineral sources. Their ability to crush and grind rocks into fine particles makes them ideal for a wide range of applications in the mining industry.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding

1. What is the difference between wet ball mill and dry ball mill?

A wet ball mill uses water to grind materials, while a dry ball mill does not.

2. Can I use my own grinding balls in a wet ball mill or dry ball mill?

Yes, you can use your own grinding balls in either type of mill.

3. How much does a wet ball mill cost compared to a dry ball mill?

The cost of a wet ball mill varies depending on the manufacturer and model, but it can range from $10,000 to $50,000 or more.

4. Will using a wet ball mill cause problems with the air quality in my mining area?

It depends on the type of materials being ground, but in general, using a wet ball mill can have some negative effects on the air quality in the area.

5. Can a wet ball mill be used to process coal? If so, how does that work?

Yes, a wet ball mill can be used to process coal, but it may require additional equipment such as classifiers and filters to separate the different minerals in the coal.

6. Are there any advantages to using a wet ball mill over a dry ball mill for mining purposes?

One advantage of using a wet ball mill is that it is less likely to cause attrition and, which can lead to lower efficiency and downtime.

7. Can a wet ball mill be used to extract gold or copper from ore?

Yes, a wet ball mill can be used to extract gold or copper from ore by passing the material through the grinding media and collecting the gold or copper byproducts.

8. How long do wet ball mills typically last?

The lifespan of a wet ball mill depends on several factors, including the size and frequency of usage, the materials being ground, and the operating conditions.

9. How do I clean a wet ball mill after use?

To clean a wet ball mill after use, remove all the used grinding media and rinse the machine thoroughly with water. Avoid soaking the machine in water or applying abrasive cleaners as they can damage the metal surfaces.

10. Is it possible to use a wet ball mill for processing other types of minerals besides gold and copper?

Yes, it is possible to use a wet ball mill for processing other types of minerals besides gold and copper, as long as the right equipment is available and the minerals are properly prepared for processing.

(Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding)

REQUEST A QUOTE

RELATED PRODUCTS

Ball mill spare parts Ball mill ring gear and gears Ball mill Gears

Hot ISO CE Certified Large Cast Steel Ball Mill Cylinder Liner Plates High Nicr Alloy Mill Liner Bearing Engine Motor Spare

Ball Mill Machine Gold Mining Ball Mill Spare Parts Equipment Portable Ceramic Ball Mill for Mining

High Capacity ball mill machine dry wet ball stone grinding gold ball mill catalytic converter parts and accessories

Factory custom mining equipment ball mill drive parts accessories Hollow shaft