PRODUCT PARAMETERS

Description

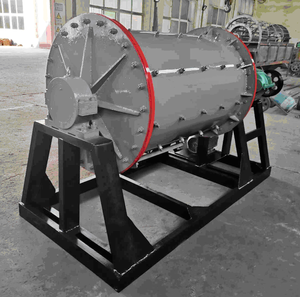

Brief introduction of Good factory Customized forged steel large diameter ring gear ball mill for drawing

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Good factory Customized forged steel large diameter ring gear ball mill for drawing refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Good factory Customized forged steel large diameter ring gear ball mill for drawing

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Good factory Customized forged steel large diameter ring gear ball mill for drawing)

Specification of Good factory Customized forged steel large diameter ring gear ball mill for drawing

Great Factory Custom-made Forged Steel Huge Size Ring Equipment Round Mill for Drawing meets industrial grinding demands. It takes care of heavy tons and runs under difficult problems. The product is developed for durability and high performance.

The ring gear uses built steel. Created steel gives strength and resistance to wear. This material makes certain long service life. The gear undertakes specific warm treatment. Heat therapy enhances hardness and strength. It lowers the threat of cracks or contortion.

Personalization is a vital attribute. Sizes and dimensions match details client needs. Large sizes are readily available for durable mills. Tooth accounts are machined accurately. Exact machining ensures smooth engagement with pinions. This reduces vibration and noise during procedure.

The manufacturing procedure includes sophisticated forging techniques. Forging gets rid of interior issues. It enhances structural honesty. CNC equipments shape the equipment teeth. CNC machining assurances accuracy. Each gear meets strict resistance standards.

These equipments suit round mills in mining, cement, and metallurgy. They transfer power effectively in grinding operations. Durable building manages continual usage. Upkeep requirements are low. This minimizes downtime and operating expense.

Quality control is extensive. Resources are checked prior to manufacturing. Each manufacturing stage undergoes checks. Finished equipments are tested for firmness and dimensional accuracy. Checking ensures dependability before shipment.

Technical assistance is provided. Designers aid with installation and upkeep. Personalized solutions deal with unique difficulties. Spare components are offered for replacements.

The item outshines standard gears. Tailored layouts fit particular machinery. High-grade products prevent premature failure. Precision production ensures regular performance. Competitive pricing supplies value for cash.

This ring equipment is a functional option for requiring applications. It incorporates strength, customization, and reliability. Industries take advantage of improved effectiveness and lowered costs.

(Good factory Customized forged steel large diameter ring gear ball mill for drawing)

Applications of Good factory Customized forged steel large diameter ring gear ball mill for drawing

The Excellent Manufacturing Facility Custom-made Forged Steel Huge Size Ring Equipment Sphere Mill serves sturdy grinding tasks in sectors such as mining, concrete, and metallurgy. It processes basic materials such as ores, cement clinker, and industrial minerals into great powders. The forged steel building makes certain high toughness and wear resistance. Personalization enables the mill to match specific functional needs, including size, lots capacity, and gear specs. This versatility makes it suitable for diverse tasks calling for customized remedies.

The round mill’s large diameter ring equipment boosts torque transmission. This design improves grinding efficiency and minimizes energy consumption. Heat-treated alloy steel parts avoid early wear under high-stress conditions. Precision machining makes certain smooth equipment engagement. This decreases vibration and sound throughout operation. Operators benefit from secure efficiency over prolonged durations.

Mining operations rely upon this equipment for grinding difficult minerals like copper, gold, and iron ore. Cement plants utilize it to grate clinker into great cement powder. Metallurgical facilities apply it for refining metal powders. The robust structure handles unpleasant materials without regular upkeep. This decreases downtime and operational costs.

The built steel manufacture method outmatches traditional actors steel. It gets rid of internal flaws like porosity or cracks. This causes higher architectural stability. The equipment teeth are machined to specific tolerances. Correct alignment prolongs life span even under hefty lots. Custom equipment modules fit differing electric motor rates and power inputs.

Severe settings require reliable machinery. This ball mill operates effectively in high-temperature or high-moisture setups. Corrosion-resistant treatments safeguard important components. Normal lubrication systems ensure consistent gear efficiency. Operators can adjust grinding fineness by changing specifications like rotational rate or material feed rate.

Commercial tasks focus on resilience and performance. The Excellent Manufacturing facility ball mill fulfills these needs via advanced design. Its design focuses on decreasing mechanical failures. This assures undisturbed production cycles. Minimized maintenance requirements reduced lasting ownership costs.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Good factory Customized forged steel large diameter ring gear ball mill for drawing

What customization options do you offer for forged steel large diameter ring gears?

Our factory provides tailored solutions for ring gears. We adjust dimensions, tooth profiles, material grades based on customer needs. Custom designs accommodate specific load capacities, rotational speeds, operating environments. Technical teams work closely with clients to ensure precise specifications.

Why choose forged steel for large ring gears in ball mills?

Forged steel offers superior strength, durability compared to cast alternatives. The forging process aligns grain structures, enhancing resistance to wear, impact, fatigue. This material handles heavy loads, high-stress conditions in mining, cement industries. It ensures long-term reliability, reduces downtime.

How do you ensure quality control during production?

Quality checks occur at every stage. Raw materials undergo chemical, mechanical testing before use. Forging, machining, heat treatment follow strict protocols. Finished gears pass hardness tests, dimensional inspections, non-destructive testing. Certifications like ISO guarantee compliance with international standards.

What maintenance practices extend the lifespan of ring gears?

Regular lubrication prevents friction, wear. Inspect teeth for cracks, pitting periodically. Misalignment, overloading should be avoided. Replace damaged sections early to prevent further issues. Proper maintenance schedules are provided with each product.

What is the typical delivery time for customized orders?

Production time depends on size, complexity. Standard orders take 8–12 weeks. Larger diameters, unique specifications may require more time. We communicate timelines clearly after reviewing design requirements. Expedited options are available for urgent projects.

(Good factory Customized forged steel large diameter ring gear ball mill for drawing)

REQUEST A QUOTE

RELATED PRODUCTS

Diatomaceous earth powder ball mill plant ,Baichy the professional crushing equipment

Ball mill spare parts ZQCr10 high chrome casting alloy grinding ball

Customized for various sizes spare parts Casting Steel Rotary Kiln Ball Mill Rod Mill end cover

Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From

Overflow ball mill Mining Equipment Machine s/Grinding Mill/Rod Mill for Hematite, Iron Ore, Bentonite, Limestone, Cement