PRODUCT PARAMETERS

Description

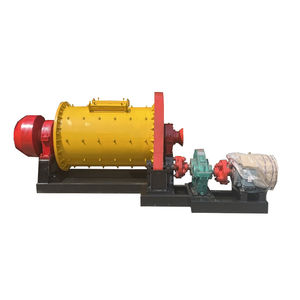

Brief introduction of Good Reputation of Ball Mills s Ball Mill Grinder s 900×1800 Ball Grinding Machine

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Good Reputation of Ball Mills s Ball Mill Grinder s 900×1800 Ball Grinding Machine refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Good Reputation of Ball Mills s Ball Mill Grinder s 900×1800 Ball Grinding Machine

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Good Reputation of Ball Mills s Ball Mill Grinder s 900×1800 Ball Grinding Machine)

Specification of Good Reputation of Ball Mills s Ball Mill Grinder s 900×1800 Ball Grinding Machine

The 900×1800 Ball Grinding Machine is a reliable choice for grinding materials in mining, cement, and chemical industries. Its design focuses on efficiency and durability. The cylinder measures 900mm in diameter and 1800mm in length. This size balances processing capacity and energy use. The machine operates smoothly under heavy loads. It handles both wet and dry grinding methods.

The ball mill uses high-quality steel plates welded for structural strength. The inner lining includes wear-resistant materials like manganese steel or rubber. These materials extend service life. The motor power ranges from 18.5kW to 22kW. Rotation speed stays at 36-38 rpm. This setup ensures stable operation. Grinding media like steel balls are added based on material hardness. The maximum feed size is 20mm. Output fineness adjusts between 0.075mm and 0.89mm.

Users praise its low maintenance needs. The gearbox and bearings are sealed to prevent dust entry. Lubrication points are easy to access. The machine reduces downtime. Operators report consistent particle size distribution. It works well for ceramics, ores, and cement clinker.

The 900×1800 model consumes less energy than similar machines. Its optimized rotation speed cuts power waste. Heat generation stays low during long runs. This protects internal parts. Noise levels remain under 85 decibels. Safety features include emergency stops and overload protection.

Customers highlight its cost-effectiveness. The initial investment pays off through reduced repair costs. Spare parts like liners and gears are widely available. Technical support responds quickly to issues. Training manuals come with clear instructions.

This ball mill suits small to medium production lines. It handles continuous operation for 24-hour facilities. Installation requires a flat concrete foundation. Maintenance checks focus on lubrication and bolt tightness. The machine’s reputation grows from its balance of performance and affordability.

(Good Reputation of Ball Mills s Ball Mill Grinder s 900×1800 Ball Grinding Machine)

Applications of Good Reputation of Ball Mills s Ball Mill Grinder s 900×1800 Ball Grinding Machine

The Ball Mill Grinder 900×1800 Ball Grinding Machine is known for its reliability and performance. Industries like mining, cement production, ceramics, and chemicals rely on it. It handles materials such as ores, cement clinker, silica sand, and pigments. The machine grinds these materials into fine powders. Its design ensures consistent results.

This ball mill’s structure is built to last. Heavy-duty steel frames and quality liners reduce wear. The rotating drum uses steel balls to crush materials efficiently. This method works for wet and dry grinding. Users save energy while maintaining output. Lower power consumption cuts operational costs. Maintenance is straightforward. Accessible parts and simple design reduce downtime.

The 900×1800 model suits small to medium operations. Laboratories and pilot plants use it for testing. It scales up for full production without losing efficiency. Adjusting rotation speed changes particle size. This flexibility meets different industry needs.

Durability is a key advantage. High-grade materials in critical parts extend the machine’s life. Bearings and gears are designed for heavy loads. This reduces breakdowns. Operators focus on productivity instead of repairs.

The machine’s reputation comes from proven performance. Mines process ores consistently. Cement plants achieve uniform clinker grinding. Ceramic factories produce fine glazes. Chemical industries mix powders evenly. Each application benefits from precise control.

Safety features protect workers. Emergency stops and secure covers prevent accidents. The design meets industry safety standards. Training operators is simple. Clear guidelines ensure smooth use.

The 900×1800 Ball Grinding Machine fits tight spaces. Compact size works in limited areas. Installation requires minimal setup. It integrates into existing production lines easily.

Businesses choose this machine for reliability. It handles tough materials without faltering. Consistent output supports quality control. Lower energy use and maintenance costs improve profitability. This machine remains a trusted tool in material processing.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Good Reputation of Ball Mills s Ball Mill Grinder s 900×1800 Ball Grinding Machine

What makes the 900×1800 Ball Grinding Machine durable? The machine uses high-quality steel for its main structure. It has wear-resistant liners inside the grinding chamber. These parts reduce damage from constant friction. Regular maintenance checks help keep components working longer. The design focuses on minimizing wear over time.

How does this ball mill ensure grinding efficiency? The 900×1800 model has a balanced rotating cylinder. This allows even distribution of grinding media like steel balls. The motor power matches the drum size. This balance prevents energy waste. Materials are ground uniformly to the desired fineness.

What materials can this ball mill handle? It processes metals like gold and copper. It works for industrial minerals like quartz and feldspar. Ceramic materials and cement raw mixes are also suitable. Hardness levels up to a Mohs scale of 9 are manageable. Wet or dry grinding methods can be used.

Is the machine easy to maintain? Daily checks involve inspecting bolts and lubrication points. Lubricant must be added to gears weekly. Worn liners or grinding media should be replaced every 6-12 months. Cleaning the machine after use prevents material buildup. Basic tools are enough for most tasks.

Why is this ball mill cost-effective? The initial price is lower than larger industrial models. Energy use stays efficient due to smart motor design. Long-lasting parts reduce replacement costs. Downtime is minimal with proper maintenance. It suits small to medium production needs without overspending.

(Good Reputation of Ball Mills s Ball Mill Grinder s 900×1800 Ball Grinding Machine)

REQUEST A QUOTE

RELATED PRODUCTS

OEM customize cast alloy ball mill liners wear resistant lining plate spare parts

South Africa Good Ball Mill Gear for Platinum, Chrome Ore Grinding Mill Mining Ball Mill

Customized for various sizes spare parts Casting Steel Rotary Kiln Ball Mill Rod Mill end cover

Effective Large Capacity Ball.Mill Ball Mill For Mining

High-Quality High Manganese Steel Ball Mill Liners Reliable Wear Spare Parts for Ball Mills