PRODUCT PARAMETERS

Description

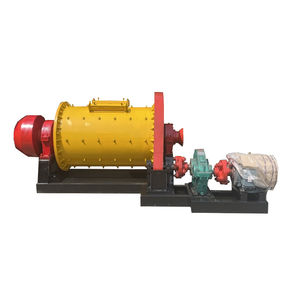

Brief introduction of High Quality Factory Supply Mining Cement limestone powder rotary dry wet gold copper ore Grinding Ball Mill

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. High Quality Factory Supply Mining Cement limestone powder rotary dry wet gold copper ore Grinding Ball Mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of High Quality Factory Supply Mining Cement limestone powder rotary dry wet gold copper ore Grinding Ball Mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(High Quality Factory Supply Mining Cement limestone powder rotary dry wet gold copper ore Grinding Ball Mill)

Specification of High Quality Factory Supply Mining Cement limestone powder rotary dry wet gold copper ore Grinding Ball Mill

Premium Quality Factory Supply Mining Concrete Limestone Powder Rotary Dry Wet Gold Copper Ore Grinding Sphere Mill is a robust and flexible industrial grinding machine developed for handling numerous materials, including cement, sedimentary rock, gold, copper ore, and other minerals. It is crafted for both completely dry and wet grinding procedures, guaranteeing adaptability to various manufacturing needs. The mill is constructed with exceptional products and progressed production strategies, assuring durability, performance, and long life span in extreme mining and industrial settings.

** Secret Attributes: **.

– ** Handling Capacity: ** The mill handles a wide range of capacities, from 0.65 to 615 heaps per hour, depending upon model specs and material properties.

– ** Grinding Media: ** Utilizes high-chromium steel balls or ceramic spheres for efficient grinding, lowering energy intake while making the most of outcome fineness.

– ** Drum Dimensions: ** Available in diameters varying from 900 mm to 5500 mm and lengths from 1800 mm to 8500 mm, satisfying diverse manufacturing scales.

– ** Motor Power: ** Equipped with high-torque electric motors (18.5 kW to 4500 kW) for secure procedure under heavy tons.

– ** Rotational Rate: ** Flexible speed between 12 to 38 RPM, optimized for material type and wanted bit size.

– ** Material Compatibility: ** Ideal for grinding unpleasant and non-abrasive products, with linings constructed from manganese steel, rubber, or ceramic to prevent wear.

– ** Discharge System: ** Includes overflow or grate discharge systems for specific control over product granularity.

– ** Functional Modes: ** Supports both open-circuit and closed-circuit grinding configurations, with optional assimilation right into automated control systems.

** Technical Specifications: **.

– ** Max Feed Size: ** ≤ 25 mm for dry grinding; ≤ 5 mm for damp grinding.

– ** Final Product Fineness: ** Adjustable from 0.074 mm to 0.4 mm.

– ** Cooling System: ** Optional water-cooling or air-cooling systems to keep optimal operating temperatures.

– ** Safety Characteristics: ** Consists of emergency quit devices, overload security, and resonance sensors for risk-free procedure.

– ** Customization: ** Available in tailored styles, consisting of gear-driven or pulley-driven versions, and variable-speed drives.

** Applications: ** Ideal for concrete plants, extracting procedures, metallurgy, chemical sectors, and power generation. The mill ensures consistent efficiency in creating carefully ground materials for downstream procedures like flotation, leaching, or concrete blending.

** Quality control: ** Made under stringent quality control standards, with components checked for hardness, impact resistance, and deterioration resistance. Complies with ISO, CE, and other worldwide accreditations.

** After-Sales Support: ** Includes setup advice, operator training, and accessibility to spare parts such as linings, gears, and bearings.

This grinding ball mill integrates high effectiveness, integrity, and low upkeep, making it a cost-effective option for commercial grinding demands.

(High Quality Factory Supply Mining Cement limestone powder rotary dry wet gold copper ore Grinding Ball Mill)

Applications of High Quality Factory Supply Mining Cement limestone powder rotary dry wet gold copper ore Grinding Ball Mill

The Excellent Quality Manufacturing Facility Supply Mining Concrete Limestone Powder Rotating Dry Damp Gold Copper Ore Grinding Ball Mill is a robust and flexible industrial equipment made to efficiently grind a wide variety of materials, consisting of sedimentary rock, cement clinker, gold ore, copper ore, and various other minerals. Engineered for longevity and efficiency, this ball mill is perfect for mining, cement production, and mineral processing markets, using reliable operation in both dry and wet grinding applications.

** Applications: **.

This grinding ball mill is widely utilized in the processing of raw materials for concrete production, where sedimentary rock and various other additives are ground right into fine powder. In mining procedures, it processes gold, copper, and other metal ores, minimizing particle size for succeeding removal or leaching. The device is likewise suitable for grinding coal, porcelains, and chemical products, making it a multi-functional possession across sectors. Its ability to deal with damp and completely dry grinding makes sure flexibility to differing functional demands.

** Trick Attributes: **.

The rotating round mill operates a rotating cylinder concept, utilizing steel rounds as grinding media to crush and blend materials into uniform uniformity. Its heavy-duty building consists of high-quality wear-resistant linings and equipments, ensuring durability also under continual use. The mill’s layout lessens energy intake while taking full advantage of throughput, enhancing cost-efficiency. Flexible rotation speed permits operators to optimize grinding time and excellence, accommodating certain material homes.

** High quality & Efficiency: **.

Manufactured under stringent quality assurance requirements, this ball mill guarantees accuracy engineering and constant output. It is developed to endure extreme environments, with closed bearings and lubrication systems lowering upkeep demands. The device’s big capability and high grinding performance make it appropriate for massive industrial operations, providing great powders with regulated particle dimension distribution.

** Power Effectiveness & Environmental Advantages: **.

Geared up with innovative electric motor modern technology and optimized auto mechanics, the mill lowers power consumption contrasted to traditional versions. Its closed-circuit grinding system reduces dirt exhausts, aligning with ecological regulations.

** Personalization: **.

Offered in different sizes and arrangements, the ball mill can be tailored to meet particular production needs, consisting of ability, product circulation, and automation assimilation.

Ideal for mining business, cement plants, and mineral processors, this grinding sphere mill integrates resilience, performance, and flexibility, making it a critical element in contemporary product handling workflows.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High Quality Factory Supply Mining Cement limestone powder rotary dry wet gold copper ore Grinding Ball Mill

What materials can the High Quality Factory Supply Mining Cement Limestone Powder Rotary Dry Wet Gold Copper Ore Grinding Ball Mill process? This ball mill is designed to handle a wide range of materials, including limestone, cement clinker, gold ore, copper ore, and other metallic or non-metallic minerals. It supports both dry and wet grinding processes, making it versatile for mining, cement production, and industrial mineral processing. The robust construction ensures efficient grinding of hard and abrasive materials.

How does the grinding process work in this ball mill? The ball mill operates by rotating a cylindrical chamber filled with grinding media, such as steel balls. As the cylinder rotates, the balls lift and cascade, crushing and grinding the material through impact and friction. The ground material is discharged through a sieve plate, ensuring consistent particle size. Adjusting the rotation speed or grinding media size allows control over the fineness of the output.

What is the difference between dry and wet grinding modes? Dry grinding processes materials without added liquid, ideal for moisture-sensitive applications like cement production. Wet grinding involves water or other liquids, reducing dust and improving efficiency for materials like gold or copper ore. The choice depends on the material properties and end-use requirements. This ball mill is engineered to handle both methods seamlessly.

What maintenance is required for this ball mill? Regular maintenance includes checking the wear of liners and grinding media, lubricating bearings and gears, and inspecting electrical components. Cleaning residual material from the chamber and ensuring bolts are tightened prevents operational issues. Scheduled downtime for part replacements ensures longevity and minimizes unexpected breakdowns, maintaining high efficiency.

What advantages does this ball mill offer over competitors? It combines high grinding efficiency, durability, and adaptability. The heavy-duty design reduces wear, while the energy-efficient motor lowers operational costs. Its ability to process both dry and wet materials across industries—mining, cement, metallurgy—makes it a versatile investment. Advanced sealing prevents leaks, and the modular structure simplifies maintenance, ensuring reliable, continuous operation in demanding environments.

(High Quality Factory Supply Mining Cement limestone powder rotary dry wet gold copper ore Grinding Ball Mill)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Supply Ball Mill Parts Low Gold Ball Mill Machine Portable Ball Mill Grinding Machine for

Coal mill in thermal power plant centrifugal fan oil filter element spare parts ball mill coal mill to generate electricity

Low Cost Factory Directly Spare Parts of Grinding Ball Mill Provided AC Motor Viet Nam Ball Milling Machine Energy & Mining

Manufacture super good quality Resistant Mining Spare Parts ball mill rubber lining

Ball Mill Machine Gold Mining Ball Mill Spare Parts Equipment Portable Ceramic Ball Mill for Mining