PRODUCT PARAMETERS

Description

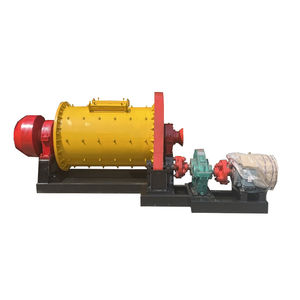

Brief introduction of Long Service Life Raw Material Ball Mill Ball Mill Alumina Grinding Ball Mill For Aluminium Powder

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Long Service Life Raw Material Ball Mill Ball Mill Alumina Grinding Ball Mill For Aluminium Powder refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Long Service Life Raw Material Ball Mill Ball Mill Alumina Grinding Ball Mill For Aluminium Powder

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Long Service Life Raw Material Ball Mill Ball Mill Alumina Grinding Ball Mill For Aluminium Powder)

Specification of Long Service Life Raw Material Ball Mill Ball Mill Alumina Grinding Ball Mill For Aluminium Powder

This product is a long-service-life basic material sphere mill created for grinding aluminium powder. It uses high-grade alumina ceramic grinding balls. These balls are made from high-purity alumina. They guarantee minimal wear during grinding. This lowers contamination in the end product. The ball mill’s framework is built for longevity. The alumina lining inside the mill stands up to corrosion. It handles high-speed rotation without degradation. This prolongs the equipment’s operational life expectancy. The grinding rounds have high solidity. They keep form under hefty impact. This guarantees consistent grinding efficiency. The uniform size of the balls improves material processing. It develops also particle circulation in aluminium powder. The mill operates silently. It generates much less warmth contrasted to conventional steel balls. This is crucial for heat-sensitive materials. The alumina grinding media is chemically inert. It does not respond with aluminium powder. This maintains product purity. The mill appropriates for both damp and completely dry grinding. It adjusts to various industrial environments. The layout focuses on very easy maintenance. Parts are replaceable without taking apart the whole system. This lessens downtime. Power usage is optimized. The reliable grinding procedure decreases power use. This decreases operational costs. The item is optimal for markets like paints, finishes, and metal powders. It fulfills stringent top quality criteria for fineness and consistency. The alumina grinding spheres are sintered at high temperatures. This boosts their thickness and toughness. They hold up against long term use without breaking. The mill’s capacity varies from little lab-scale models to huge production units. Personalized setups are readily available. Users can adjust rotation speed and filling capacity. This versatility suits different production needs. The devices adheres to safety guidelines. Protective attributes avoid overheating and mechanical failures. Regular lubrication guarantees smooth operation. The alumina components are environmentally friendly. They create no poisonous deposits. This straightens with sustainable production techniques. The product’s dependability makes it a cost-effective option. It reduces maintenance expenses gradually. High-volume manufacturing needs are fulfilled efficiently. The round mill is a practical solution for refining aluminium powder. It stabilizes performance and longevity.

(Long Service Life Raw Material Ball Mill Ball Mill Alumina Grinding Ball Mill For Aluminium Powder)

Applications of Long Service Life Raw Material Ball Mill Ball Mill Alumina Grinding Ball Mill For Aluminium Powder

Long life span raw material sphere mills are important for grinding light weight aluminum powder efficiently. These devices use alumina grinding balls known for their hardness and durability. The alumina balls resist deterioration even under high-impact conditions. This makes them excellent for processing abrasive materials like aluminum powder.

The ball mill’s layout concentrates on regular efficiency. The alumina grinding media decreases contamination during the grinding process. Aluminum powder requires purity for applications in sectors such as aerospace and automobile. Contamination dangers are decreased since alumina ceramic is chemically inert. This ensures the final product fulfills strict high quality standards.

Alumina grinding rounds last longer than steel or various other steels. Their reduced wear price cuts downtime for replacements. This conserves expenses over time. The balls keep sizes and shape also after expanded usage. This stability assurances uniform bit dimension in light weight aluminum powder. Uniform particles boost item efficiency in applications such as finishings or pyrotechnics.

The sphere mill operates smoothly in severe settings. High temperatures and destructive products do not affect its efficiency. The alumina grinding media holds up against thermal stress and anxiety. This reliability makes the mill suitable for continuous commercial operations. Manufacturing facilities take advantage of lowered maintenance and higher performance.

Aluminum powder generated by these mills is utilized extensively. It serves as a base product in paints, nitroglycerins, and 3D printing. The powder’s great appearance and consistency are crucial for these applications. The sphere mill’s precision grinding ensures these buildings are attained constantly.

Energy effectiveness is one more advantage. The mill’s layout lowers power usage while keeping output. Reduced power use straightens with sustainability goals. Firms reduce functional expenses without jeopardizing on product quality.

Maintenance is uncomplicated. The durable building and construction of the mill and grinding media indicates less break downs. Regular checks concentrate on fundamental components like electric motors and liners. This simplicity keeps operational workflows uninterrupted.

Industries calling for high-purity aluminum powder rely upon these mills. Electronic devices manufacturers utilize the powder for conductive pastes. Chemical plants use it in catalysts. The versatility of the ball mill meets varied commercial requirements.

The combination of resilient materials and efficient style makes this equipment a practical financial investment. It attends to both efficiency and cost obstacles in aluminum powder manufacturing. Businesses attain greater outcome with less sources.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Long Service Life Raw Material Ball Mill Ball Mill Alumina Grinding Ball Mill For Aluminium Powder

What makes the alumina grinding ball mill last long?

The alumina grinding ball mill uses high-quality alumina ceramic materials. These materials have high wear resistance. They handle tough grinding conditions without breaking down fast. The design focuses on reducing friction between parts. This cuts wear and tear. The result is a longer service life compared to regular steel ball mills.

Why choose alumina balls for grinding aluminium powder?

Alumina balls are hard and dense. They grind aluminium powder efficiently. They generate less heat during grinding. This prevents the aluminium powder from overheating. Overheating can cause safety risks or damage the powder’s quality. Alumina also resists chemical reactions with aluminium. This keeps the powder pure.

How often does the ball mill need maintenance?

The ball mill requires minimal maintenance. Check the lining and grinding balls every 500 hours of use. Replace worn or cracked parts immediately. Lubricate moving parts every 150 hours. Proper maintenance ensures consistent performance. It also extends the machine’s lifespan.

Is the ball mill safe for aluminium powder processing?

Yes. The mill’s design prevents sparks during operation. Alumina materials are non-flammable. This reduces fire risks. The grinding process is sealed to stop powder from leaking. Leaks can create dust explosions. The system includes safety valves to control pressure. Operators must still follow standard safety protocols.

Can the ball mill handle different batch sizes?

Yes. The mill comes in multiple sizes. Small batches use compact models. Large-scale production needs bigger units. Adjust the speed and grinding time to match the batch size. Customizable settings let users optimize the process. This flexibility works for labs and factories.

(Long Service Life Raw Material Ball Mill Ball Mill Alumina Grinding Ball Mill For Aluminium Powder)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Hot Lab Ball Mill for

South Africa Good Ball Mill Gear for Platinum, Chrome Ore Grinding Mill Mining Ball Mill

High crushing ratio 5 10 15 tons per hour cement mineral grinding ball mill with spare parts for gold silver copper crushing

Ball Mill mining Equipment Accessories Hollow Shaft ball Mill Hollow Shaft For Material Feeding And Discharging