PRODUCT PARAMETERS

Description

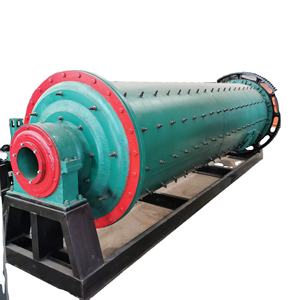

Brief introduction of Manufacture ball mill for gold mining 900×3000 ball mill grinding machine

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Manufacture ball mill for gold mining 900×3000 ball mill grinding machine refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Manufacture ball mill for gold mining 900×3000 ball mill grinding machine

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Manufacture ball mill for gold mining 900×3000 ball mill grinding machine )

Specification of Manufacture ball mill for gold mining 900×3000 ball mill grinding machine

The 900×3000 ball mill is a durable grinding machine made for gold mining operations, crafted to deliver efficient and reputable performance in processing gold-bearing ores. This ball mill is built with a round covering measuring 900mm in size and 3000mm in size, created from high-grade steel to endure rough mining atmospheres. The mill operates on the concept of effect and attrition, utilizing steel spheres as grinding media to minimize ore fragments to the preferred excellence.

Secret specs include an optimum packing capacity of approximately 7-8 lots of grinding media (steel rounds), with an advised sphere dimension series of 25mm to 75mm depending on ore solidity. The mill’s drum rotates at an essential rate of 28-32 RPM, powered by an electric motor rated at 55-75 kW, ensuring optimal grinding performance. The equipment features a gear-driven transmission system for smooth operation and includes a sturdy lining plate (rubber or manganese steel) to shield the internal shell from wear and lengthen life span.

Designed for damp or dry grinding, the 900×3000 ball mill refines approximately 1-3 lots of ore per hour, achieving a discharge bit dimension of 0.074-0.4 mm, appropriate for subsequent gold extraction processes like cyanidation or flotation protection. It includes a feed inlet with a trunnion or chute layout for regulated material input and a discharge end outfitted with a display to keep grinding media while allowing ground slurry to exit.

Safety attributes consist of overload security, emergency stop devices, and a strengthened base framework for security. The mill needs a foundation efficient in supporting its total weight (approx. 12-15 lots) and works with complementary tools such as classifiers, pumps, and cyclones. Upkeep involves routine examination of liners, lubrication of bearings, and monitoring of equipment alignment. Ideal for small to medium-scale gold mining, this ball mill equilibriums productivity, longevity, and power performance, making it a vital component in ore processing circuits.

(Manufacture ball mill for gold mining 900×3000 ball mill grinding machine )

Applications of Manufacture ball mill for gold mining 900×3000 ball mill grinding machine

The 900×3000 sphere mill is a robust grinding equipment engineered for gold mining procedures, created to effectively refine gold-bearing ores into great powders for optimal steel healing. With a cylinder diameter of 900mm and size of 3000mm, this medium-sized round mill balances capacity and flexibility, making it optimal for small to mid-scale mining jobs. Its applications span critical points of gold ore processing, making certain high performance and dependability.

** Main Grinding: ** The 900×3000 round mill is mainly utilized to grind smashed gold ore into great fragments, liberating gold from surrounding rock. This action is essential for taking full advantage of surface area exposure, which improves chemical leaching or cyanidation performance. The machine’s rotating drum, loaded with steel rounds, crushes ore with influence and friction, achieving consistent bit dimensions necessary for downstream procedures.

** Secondary Grinding: ** In circuits calling for better grinding, this sphere mill acts as a secondary unit, additional minimizing fragment size to boost gold recovery rates. It incorporates flawlessly with crushers, classifiers, and concentrators, making sure a continual and reliable handling flow.

** Material Homogenization: ** Past grinding, the mill mixes ores of varying grades, guaranteeing constant feed high quality for seeping or flotation. This homogenization minimizes handling variability, stabilizing recovery outcomes.

** Secret Attributes: **.

– ** Durable Building: ** Built with top quality steel, abrasion-resistant liners, and enhanced components to endure harsh mining atmospheres.

– ** Energy Efficiency: ** Optimized turning speed and grinding media reduce power usage while maintaining outcome.

– ** Reduced Upkeep: ** Easy-access layout streamlines evaluation, liner substitute, and regular upkeep, reducing downtime.

– ** Flexibility: ** Manages varied ore types, consisting of wet or completely dry materials, and adjusts to varying solidity levels.

** Conveniences for Gold Mining: **.

– ** Improved Healing: ** Constant grind quality boosts gold extraction prices throughout seeping or gravity separation.

– ** Economical Procedure: ** Sturdy materials and effective style reduced lasting operational and maintenance expenses.

– ** Scalability: ** Suitable for modular arrangements or expanding assembly line, supporting growing functional needs.

The 900×3000 ball mill is a foundation of gold processing, offering integrity, performance, and precision. Its layout focuses on miner requirements, supplying performance that drives productivity and earnings in affordable mining settings.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Manufacture ball mill for gold mining 900×3000 ball mill grinding machine

What are the key technical specifications of the 900×3000 ball mill for gold mining? The 900×3000 ball mill has a drum diameter of 900 mm and length of 3000 mm, powered by a 55–75 kW motor. It operates at a rotation speed of 36–38 RPM and holds a maximum grinding media load of 3.5 tons. Designed for wet or dry grinding, it efficiently processes gold ore into fine particles, with a discharge size adjustable between 0.074–0.4 mm. Its robust construction includes high-quality steel plates and liners for durability.

What is the processing capacity of the 900×3000 ball mill? This ball mill processes 1.5–2.5 tons of gold ore per hour, depending on ore hardness, feed size, and desired output fineness. For softer ores, throughput may increase, while harder ores require longer grinding cycles. Optimal performance is achieved when paired with a classifier to recycle coarse material, ensuring consistent particle size and maximizing gold recovery rates.

What grinding media materials are suitable for this ball mill? Steel balls (high-carbon or alloy steel) are standard due to their density and wear resistance. For gold ores requiring minimal contamination, ceramic or rubber-lined drums with stainless steel or alumina balls are recommended. Media size (25–100 mm) should match ore characteristics—smaller balls for fine grinding, larger ones for coarse feed.

How often does the 900×3000 ball mill require maintenance? Routine checks include lubricating bearings every 8–10 hours and inspecting liners every 3–6 months. Replace worn liners or grinding media when thickness drops below 60%. Gear and motor inspections should occur every 6–12 months. Proper maintenance reduces downtime and extends the machine’s lifespan to 8–10 years under normal use.

What safety features are included? The mill includes overload protection to halt operations during voltage spikes or mechanical stress, emergency stop buttons, and safety guards covering rotating parts. Ventilation systems minimize dust exposure, and anti-vibration pads reduce noise. Operators must follow lockout/tagout procedures during maintenance. Compliance with ISO and mining safety standards ensures reliable operation in harsh environments.

(Manufacture ball mill for gold mining 900×3000 ball mill grinding machine )

REQUEST A QUOTE

RELATED PRODUCTS

Casting High Quality and Long Use Time Ball Mill Diaphragm Excellent Performance Ball Mill Spare Parts Ball Mill Liners

Ball Mill Liner Plate Lining For Mining Grinding Machine s lining of the ball mill

Wet Small Ball Mill Grinding Machine Spare Parts for in Zimbabwe

Ball mill wear-resistant parts high chromium solid steel ball steel section cast alloy steel ball

Customized Large Ball Mill Liner New Casting Parts for Ore Mining Mining Machinery Processing