PRODUCT PARAMETERS

Description

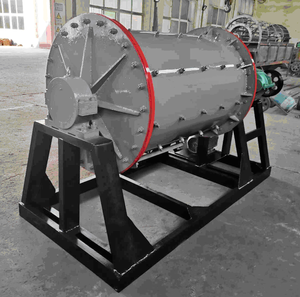

Brief introduction of Mini ball mill for coal

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Mini ball mill for coal refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Mini ball mill for coal

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Mini ball mill for coal)

Specification of Mini ball mill for coal

The Mini Ball Mill for Coal is a compact grinding machine. It refines coal right into great powder for industrial usage. The device collaborates with coal, charcoal, and coke. It fits small operations and research laboratory testing. The layout focuses on efficiency and durability. The body makes use of stainless-steel or sturdy alloy. This stops rust and use during grinding.

The mill runs with a revolving chamber filled with steel spheres. Coal gets in the chamber through a feed receptacle. The rotating movement crushes the product in between the balls. Fragment dimension readjusts by altering the turning rate. Rate ranges from 50 to 300 RPM. Better powder requires longer grinding times.

The equipment consists of a motor with overload defense. Power scores vary between 0.5 kW and 2.2 kW. Voltage choices cover 110V, 220V, and 380V. This makes sure compatibility with various power supplies. The mill has a built-in cooling system. It prevents overheating throughout expanded use.

Capability depends on the version. Set dimensions vary from 2 liters to 10 litres. Feed product dimension stays below 10 mm. Result fragment size can reach 50 microns. A control panel manages rate and procedure time. Digital displays program real-time information for precision.

Safety and security attributes include emergency situation quit buttons and safety covers. These decrease threats during procedure. The portable size saves work area. Weight stays in between 30 kg and 80 kg. This permits simple moving.

Maintenance includes regular cleansing and lubrication. Damaged spheres and linings are replaceable. Extra parts are widely offered. The equipment operates in laboratories, pilot plants, and little manufacturing facilities. It supports research, product testing, and sample prep work.

Technical requirements cover motor kind, chamber volume, and sound degrees. Noise remains below 75 decibels. The structure utilizes screws for fast disassembly. This streamlines cleansing and part replacement. Seals protect against dust leak throughout grinding.

Users need fundamental training for risk-free operation. Manuals offer setup and repairing guides. The maker satisfies sector requirements for coal handling. It balances efficiency, price, and area demands.

(Mini ball mill for coal)

Applications of Mini ball mill for coal

A mini round mill for coal is a small grinding device. It breaks coal right into great powder for numerous usages. This devices is tiny in dimension. It fits well in labs, small factories, and field settings. The mini round mill works by turning a chamber filled with steel balls. Coal is added, and the balls squash it right into powder via duplicated accidents. This procedure makes certain effective grinding even with limited room.

The primary use a miniature ball mill is coal sample prep work. Labs and proving ground count on it to evaluate coal high quality. Grinding coal right into fine fragments helps evaluate residential properties like dampness, ash content, and calorific worth. Consistent particle dimension improves screening precision. Universities additionally make use of miniature sphere mills for teaching. Trainees find out about coal processing and grinding mechanics hands-on.

Small-scale markets benefit from mini round mills. These mills support minimal coal processing for local services. Craft workshops, brick kilns, and pottery units use coal powder as fuel. The mini sphere mill offers consistent result for such requirements. Backwoods with uneven power supply locate it beneficial. Its low energy need fits off-grid procedures.

One more application is blending coal with ingredients. Mixing coal with materials like lime or biomass enhances burning efficiency. The mini ball mill evenly blends elements during grinding. This develops identical gas blends. Ecological projects use this technique to lower emissions from coal.

Portability is a crucial advantage. Mini ball mills are very easy to transportation. Area rock hounds lug them for on-site coal evaluation. Mining sites utilize them to evaluate raw coal prior to large processing. Maintenance is simple. Most parts are replaceable without technological know-how.

Cost-effectiveness makes mini sphere mills popular. They are less expensive than industrial mills. Startups and small businesses save on initial investments. The portable style minimizes functional space requirements. Durability ensures long-lasting use despite frequent grinding jobs.

Mini ball mills adapt to different coal kinds. Bituminous, sub-bituminous, and lignite coal can all be refined. Adjusting rotation rate or grinding time controls particle size. This adaptability satisfies diverse individual demands.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Mini ball mill for coal

What is a mini ball mill for coal? A mini ball mill for coal is a small machine designed to grind coal into fine powder. It uses rotating cylinders filled with steel balls to crush and mix coal particles. The machine works by rotating the cylinder, causing the balls to drop and collide with the coal. This process breaks down the coal into smaller, uniform particles suitable for burning or further processing. Its compact size makes it ideal for labs or small-scale operations.

Why choose a mini ball mill for coal processing? Mini ball mills are efficient for grinding coal to precise sizes. They require less space and energy compared to larger mills. The design ensures consistent particle size distribution, improving combustion efficiency. These mills are easy to operate and maintain. They are cost-effective for small batches or research purposes. Their portability allows flexible use in different settings.

What is the typical capacity of a mini ball mill for coal? Capacity depends on the model and coal type. Most mini ball mills process 1 to 5 kilograms of coal per hour. Harder coal types may reduce output. Adjusting the grinding time or ball size can optimize results. Check the manufacturer’s specifications for exact details. Overloading the mill can damage components or lower efficiency.

How do you maintain a mini ball mill for coal? Clean the mill after each use to remove coal dust. Inspect steel balls for wear and replace damaged ones. Lubricate moving parts regularly to prevent friction. Check the motor and belts for signs of strain. Store the mill in a dry area to avoid rust. Follow the user manual for specific maintenance schedules. Proper care extends the machine’s lifespan.

Are mini ball mills safe for grinding coal? Safety features include overload protection and secure lids. The enclosed design prevents dust leakage. Emergency stop buttons are common in newer models. Always wear protective gear like gloves and goggles. Keep the mill away from flammable materials. Ensure proper ventilation in the workspace. Regular inspections reduce risks of malfunctions.

(Mini ball mill for coal)

REQUEST A QUOTE

RELATED PRODUCTS

Wet Ball Mill Spare Parts Ball Mill for in Zimbabwe

Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill

Large big 100 kg 900×3000 portable diesel engine ball mill parts for gold mining

Factory Vertical Lead Oxide Aluminum Powder Ball Mill Ceramic Balls For Ball Mill