PRODUCT PARAMETERS

Description

Brief introduction of Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill

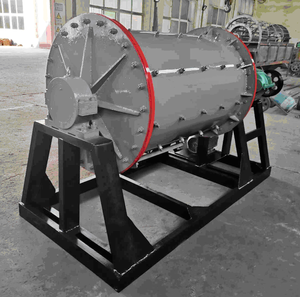

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill)

Specification of Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill

Introduction: Mining equipment spares hollow shaft discharge shaft are crucial components that ensure the smooth operation and longevity of ball mills. The quality, design, and materials used in these spares play a vital role in determining their performance, durability, and effectiveness.

Specifications:

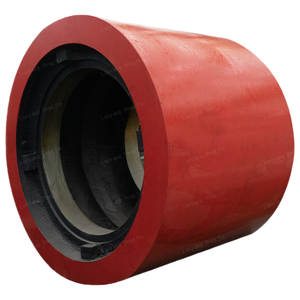

Hollow shaft discharge shafts are made from high-quality steel or other materials such as titanium or stainless steel. They are designed to be lightweight, strong, and durable, making them ideal for use in harsh environments. The diameter and length of the shaft can vary depending on the specific requirements of the ball mill, but they must meet certain standards to ensure optimal performance.

The material of the shaft is also an important factor in its performance and reliability.,。、、。

The size and length of the shaft can vary depending on the specific requirements of the ball mill.,。,,。

In conclusion, mining equipment spares hollow shaft discharge shafts are essential components that play a critical role in ensuring the smooth operation and longevity of ball mills. They must meet certain specifications to provide optimal performance and reliability. Factors such as quality, design, and materials selection all contribute to the effectiveness of these spares.

(Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill)

Applications of Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill

Hollow shaft discharge shafts play a crucial role in the operation of ball mills, providing a means of conveying materials from one point to another. These shafts are often made from high-strength materials such as steel or aluminum and are designed to withstand the wear and tear that occurs during operation.

One of the primary applications of mining equipment spares hollow shaft dischargeshaft is in the production of coal and other minerals. These shafts are used to convey the mined material from the mine site to processing facilities where it can be refined or further processed.

In addition to their use in the mining industry, hollow shaft discharge shafts are also found in other sectors such as power generation, chemical manufacturing, and agriculture. For example, in power generation, these shafts are used to transmit electricity from generators to transformers, which in turn are connected to the grid.

The hollow shaft discharge shaft is an essential component of any ball mill system, as it is responsible for conveying the mined material from the hopper to the discharge port. This helps to ensure that all of the material is conveyed efficiently and accurately, and that there is no loss of material along the way.

When it comes to replacing parts on a mining equipment spares hollow shaft discharge shaft, it is important to choose the right part for the job. The correct part will help to ensure that the shaft operates smoothly and efficiently, and that there is no damage to the machine.

In conclusion, hollow shaft discharge shafts are an essential component of any mining equipment system, and they are used in a wide range of industries to convey materials from one point to another. When choosing parts for your hollow shaft discharge shaft, it is important to consider factors such as the specific application, the material being conveyed, and the performance requirements of the machine. By doing so, you can ensure that your equipment is operating at its best and that your operations are efficient and cost-effective.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill

1. What is a hollow shaft discharge shaft for ball mill?

A hollow shaft discharge shaft is a type of mining equipment spare part used in ball mills to disperse balls efficiently and evenly. The hollow shaft design allows the balls to move freely within the ore stream, improving the grinding efficiency.

2. How does a hollow shaft discharge shaft work?

The hollow shaft discharge shaft consists of a series of holes or chambers where the balls are introduced into the ore stream. As the balls pass through these channels, they are distributed evenly throughout the ore stream, ensuring that all areas of the ore are well-mixed with the slurry.

3. Is a hollow shaft discharge shaft suitable for all types of ball mills?

Yes, a hollow shaft discharge shaft is suitable for all types of ball mills, including rod mills, attrition mills, and raymond mills. However, the specific design of the hollow shaft discharge shaft may vary depending on the requirements of the particular ball mill being used.

4. How long should a hollow shaft discharge shaft last?

The lifespan of a hollow shaft discharge shaft depends on several factors, including the quality of the material used, the operating conditions, and the maintenance frequency. In general, however, hollow shaft discharge shafts can last for several years under normal operation conditions.

5. Are there any other benefits to using a hollow shaft discharge shaft for ball milling?

In addition to improving the overall performance of the ball mill, using a hollow shaft discharge shaft can also help to reduce downtime by minimizing the need for repairs or replacements of the discharge shaft. It can also improve the safety of the operator by reducing the risk of injury from overloading or overheating the discharge shaft.

(Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill)

REQUEST A QUOTE

RELATED PRODUCTS

Liner bolts nuts sealing washers Ball mill Spare Part

High Capacity ball mill machine dry wet ball stone grinding gold ball mill catalytic converter parts and accessories

Mining Equipment Parts Ball Mill Machine Mining Equipment Sand Making Machine Ball Grinding Mill Liner Spare Parts

Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From

Large Capacity Ball Mill 3200X4500 for Crushing Chrome Ore, Spare Parts Supply All Provided AC Motor South Africa 85000