PRODUCT PARAMETERS

Description

Brief introduction of Most Searched for Tool 2023 OEM Low Good Quality Custom Liners Ball Mill Parts Cement Making Wear Resistant High Chrome

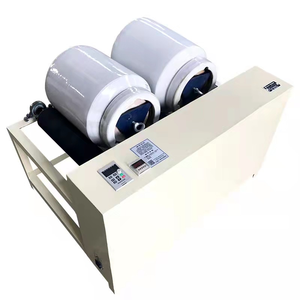

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Most Searched for Tool 2023 OEM Low Good Quality Custom Liners Ball Mill Parts Cement Making Wear Resistant High Chrome refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Most Searched for Tool 2023 OEM Low Good Quality Custom Liners Ball Mill Parts Cement Making Wear Resistant High Chrome

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Most Searched for Tool 2023 OEM Low Good Quality Custom Liners Ball Mill Parts Cement Making Wear Resistant High Chrome)

Specification of Most Searched for Tool 2023 OEM Low Good Quality Custom Liners Ball Mill Parts Cement Making Wear Resistant High Chrome

The Most Searched for Tool of 2023: OEM Low-Cost High-Quality Custom Liners for Ball Mill Parts in Cement Manufacturing. These wear-resistant, high-chrome liners are engineered to meet the rigorous demands of cement production, offering exceptional durability and cost-efficiency. Designed for ball mills, which are critical for grinding raw materials and clinker, these liners ensure extended operational life and reduced downtime in harsh industrial environments.

**Material Composition**: Crafted from high-chrome alloy steel (Cr content: 15-30%), these liners deliver superior hardness (HRC 58-65) and exceptional resistance to abrasion, impact, and corrosion. The advanced metallurgical structure ensures optimal performance even under high-stress conditions, minimizing wear rates and maintenance costs.

**Customization**: Available in tailored dimensions, thicknesses (20-100mm), and profiles to fit specific ball mill designs. Custom configurations accommodate varying grinding processes, ensuring seamless integration and maximum efficiency.

**OEM Compliance**: Manufactured to meet global OEM standards, ensuring compatibility with leading ball mill brands. Precision-engineered for dimensional accuracy (±1mm tolerance) to guarantee perfect fitment and consistent performance.

**Technical Specifications**: Impact toughness exceeds 25 Joules at -20°C, ensuring reliability in fluctuating temperatures. Surface treatments enhance wear resistance, while optimized design reduces energy consumption by up to 15% compared to conventional liners.

**Applications**: Ideal for cement raw meal grinding, clinker processing, and slag milling. Suitable for both dry and wet grinding operations across vertical and horizontal ball mills.

**Quality Assurance**: Produced under stringent quality control protocols, including X-ray analysis, ultrasonic testing, and hardness verification. ISO 9001-certified manufacturing processes ensure consistency and reliability.

**Cost-Efficiency**: Low-cost production without compromising quality reduces total ownership costs. Extended service life (2-3x longer than standard liners) minimizes replacement frequency and downtime.

**Environmental Compliance**: Eco-friendly manufacturing processes with recyclable materials align with sustainable industrial practices.

**After-Sales Support**: Comprehensive warranty, technical assistance, and global logistics ensure timely delivery and operational continuity.

These high-chrome custom liners represent the pinnacle of innovation for 2023, combining affordability, durability, and precision to revolutionize cement manufacturing efficiency. Invest in a solution that enhances productivity while slashing operational costs—engineered for the future of heavy industry.

(Most Searched for Tool 2023 OEM Low Good Quality Custom Liners Ball Mill Parts Cement Making Wear Resistant High Chrome)

Applications of Most Searched for Tool 2023 OEM Low Good Quality Custom Liners Ball Mill Parts Cement Making Wear Resistant High Chrome

In 2023, the demand for high-quality, wear-resistant OEM custom liners and ball mill parts in cement production and mining industries has surged, driven by the need for durable, cost-effective solutions. These components, crafted from high-chrome alloys, are engineered to withstand extreme abrasion, impact, and corrosion, ensuring prolonged operational efficiency in harsh environments. Their applications span critical stages of cement manufacturing and beyond, making them indispensable for modern industrial operations.

**Cement Production:** Custom liners and ball mill parts play a pivotal role in cement plants, where raw materials like limestone, clay, and clinker are ground into fine powder. High-chrome liners protect grinding chambers from rapid wear during the milling process, reducing downtime and maintenance costs. They are vital in raw mills, coal mills, and finish mills, ensuring consistent particle size distribution and energy efficiency. Their wear-resistant properties extend equipment lifespan, even under high-temperature conditions encountered in kiln feed processing.

**Mining and Mineral Processing:** Beyond cement, these components are essential in mining operations for grinding ores and minerals. High-chrome alloy liners resist abrasive materials like iron ore, copper, and gold, maintaining mill integrity and throughput. Custom designs optimize grinding efficiency, tailored to specific ore hardness and mill dimensions.

**Thermal Power Plants and Chemical Industries:** Ball mill parts are also used in coal pulverization for power generation and in chemical processing for grinding raw materials. Their robustness ensures reliable performance in continuous operations.

**Key Advantages:**

– **Wear Resistance:** High chromium content (typically 15-30%) enhances hardness and durability.

– **Customization:** OEM-specific designs ensure perfect fit and performance for diverse mill types (tube mills, SAG mills).

– **Cost Efficiency:** Reduced replacement frequency lowers long-term operational costs.

– **Sustainability:** Extended part lifespan minimizes waste and resource consumption.

Ideal for industries prioritizing productivity and reliability, these liners and parts are globally sought after for upgrading aging machinery or new installations. Manufacturers offering low-cost, high-quality OEM solutions gain a competitive edge, particularly in emerging markets with expanding infrastructure projects. Invest in high-chrome custom liners and ball mill components to optimize grinding processes, enhance output, and achieve sustainable industrial growth.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Most Searched for Tool 2023 OEM Low Good Quality Custom Liners Ball Mill Parts Cement Making Wear Resistant High Chrome

When it comes to OEM low-cost, high-quality custom liners for ball mill parts in cement manufacturing, here are the top five most searched FAQs answered directly:

**1. What makes your high-chrome custom liners stand out in cement ball mills?**

Our liners are engineered with premium high-chrome alloys (18%–30% chromium content), ensuring exceptional wear resistance in abrasive cement environments. They are custom-designed to fit specific mill dimensions, optimize grinding efficiency, and reduce energy consumption. The combination of OEM precision, durability, and cost-effectiveness makes them ideal for prolonged use in harsh conditions.

**2. How does the customization process work for ball mill liners?**

We tailor liners based on your mill’s specifications, including size, operating conditions, and material grindability. Using advanced CAD/CAM tools, we design profiles that enhance material flow and minimize wear. Custom alloy compositions are selected to match your plant’s needs, ensuring optimal performance and extended service life.

**3. Why is high-chrome steel preferred for cement mill liners?**

High-chrome steel offers superior hardness (58–65 HRC) and impact resistance, critical for withstanding constant abrasion from clinker, slag, and raw materials. Its microstructure reduces cracking and chipping, maintaining liner integrity even under high-stress conditions. This translates to fewer replacements and lower downtime costs.

**4. What is the expected lifespan of these liners compared to standard options?**

Our high-chrome liners typically last 2–3 times longer than standard manganese or low-chrome alternatives. In cement mills, lifespan varies based on operating conditions, but users report 8–12 months of service in high-abrasion zones, significantly reducing maintenance frequency.

**5. Are these liners cost-effective despite the higher chrome content?**

Yes. While the upfront cost is slightly higher, the extended lifespan and reduced downtime offset initial investments. Fewer replacements mean lower labor costs and consistent mill performance, ensuring long-term savings. Plus, our OEM pricing model keeps costs competitive without compromising quality.

These liners are trusted by global cement producers for balancing affordability, durability, and precision—key to maximizing productivity in demanding milling applications.

(Most Searched for Tool 2023 OEM Low Good Quality Custom Liners Ball Mill Parts Cement Making Wear Resistant High Chrome)

REQUEST A QUOTE

RELATED PRODUCTS

Superir Hot Low Ball Mill Grinding Machine With Lower Starting Power

Factory Supply Ball Mill Parts Low Gold Ball Mill Machine Portable Ball Mill Grinding Machine for

Ball Mill Machine Gold Mining Ball Mill Spare Parts Equipment Portable Ceramic Ball Mill for Mining

Gear Shaft For Ball Mill Spline Gear Shaft Mining Spare Parts Gear Shaft For Gearbox

Gear Shaft For Ball Mill Spline Gear Shaft Mining Spare Parts Gear Shaft For Gearbox