PRODUCT PARAMETERS

Description

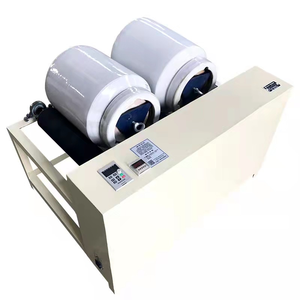

Brief introduction of Nano Super Fine Powder Grinding Machine Ce Approved Grinder For Food Industry Research Low Noise Planetary Ball Mill

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Nano Super Fine Powder Grinding Machine Ce Approved Grinder For Food Industry Research Low Noise Planetary Ball Mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Nano Super Fine Powder Grinding Machine Ce Approved Grinder For Food Industry Research Low Noise Planetary Ball Mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Nano Super Fine Powder Grinding Machine Ce Approved Grinder For Food Industry Research Low Noise Planetary Ball Mill)

Specification of Nano Super Fine Powder Grinding Machine Ce Approved Grinder For Food Industry Research Low Noise Planetary Ball Mill

The Nano Super Fine Powder Grinding Equipment is developed for the food industry. It produces ultra-fine powders with constant fragment dimensions. This device fulfills stringent CE qualification criteria. It makes certain safety and top quality in food processing applications. The mill utilizes sophisticated worldly sphere mill modern technology. This enables high-speed turning for efficient grinding. The result is a consistent texture ideal for sensitive food products.

Stainless-steel building and construction makes the machine resilient. It withstands corrosion and satisfies health needs. The grinding chamber is simple to clean. This protects against cross-contamination between sets. The machine runs at low noise degrees. This develops a quieter workspace contrasted to conventional grinders.

Processing capability ranges from little lab examples to bigger production sets. Customers adjust setups for various materials. Bit sizes can get to as low as 0.1 microns. This accuracy fits study and industrial needs. The grinder deals with dry and wet materials. It works with natural herbs, spices, artificial additive, and various other ingredients.

Safety and security functions include overload security and automatic shutdown. These avoid damages from overheating or mechanical stress and anxiety. The user interface is basic. Operators control rate and time with minimal training. Maintenance is simple. Available parts reduce downtime throughout cleansing or repair work.

Power effectiveness is a vital focus. The device consumes less power while preserving high output. Its compact style saves space in laboratories or factories. Technical assistance is available for configuration and troubleshooting. Spare parts are commonly accessible for long-lasting use.

This grinder is ideal for food research study and manufacturing. It makes sure item consistency and conformity with market requirements. The CE mark warranties adherence to European safety and security guidelines. Adjustable options include various jar dimensions and grinding media. This adaptability supports varied food handling jobs.

The planetary round mill device makes sure even grinding. Four grinding containers rotate around a central axis. Movement creates solid centrifugal pressures. This damages down materials into nano-sized fragments quickly. Rotation rates range 200 and 500 RPM. Adjustments make improvements outcomes based upon product hardness or structure.

Food-grade lubricants and seals are utilized throughout the device. These avoid contamination during operation. The closed design includes dust. This keeps a tidy working environment. Temperature level control prevents heat-sensitive ingredients from breaking down.

The equipment fits facilities prioritizing hygiene and accuracy. It integrates reliability with sophisticated modern technology. Individuals achieve repeatable results throughout sets. This reduces waste and boosts manufacturing effectiveness. Sturdiness makes sure the grinder executes consistently over years of use. Routine upkeep extends its lifespan further.

(Nano Super Fine Powder Grinding Machine Ce Approved Grinder For Food Industry Research Low Noise Planetary Ball Mill)

Applications of Nano Super Fine Powder Grinding Machine Ce Approved Grinder For Food Industry Research Low Noise Planetary Ball Mill

The Nano Super Penalty Powder Grinding Maker is a CE-approved device developed for the food sector and research study fields. It produces ultra-fine powders with high accuracy. The machine meets strict European safety and security standards. It is ideal for refining food active ingredients like seasonings, ingredients, and taste enhancers. The mill makes certain constant fragment size circulation. This is crucial for product high quality in food production.

The planetary ball mill system utilizes sophisticated modern technology. It minimizes noise throughout operation. Reduced sound degrees make it appropriate for laboratory environments. Employees can focus without disturbances. The maker’s framework lessens resonances. This enhances stability during long grinding sessions.

Materials processed include completely dry and damp materials. The grinder takes care of hard, brittle, or fibrous examples. It is built with sturdy stainless steel. This stops contamination in food-grade applications. The design permits very easy cleaning. Upkeep is easy.

Scientists use the maker for developing new food products. It sustains experiments calling for nano-sized particles. Drug labs apply it for medication formulation. Chemical markets depend on it for material testing. The grinder’s versatility makes it a crucial device across fields.

Safety and security features include overload security and automated closure. These avoid damages from overheating. The user-friendly user interface needs minimal training. Operators readjust speed and time settings rapidly. Power effectiveness lowers power intake. This cuts operational expenses.

The portable layout conserves room in labs or manufacturing areas. It works with various containers. Customers switch over between sample kinds without inconvenience. The grinding containers are watertight. This stays clear of waste throughout processing.

Food manufacturers take advantage of faster manufacturing cycles. The maker minimizes handling time by up to 50%. Uniform fragment dimension enhances product structure and solubility. This is important for instantaneous food blends or supplements.

The CE accreditation guarantees compliance with worldwide policies. It guarantees efficiency and security. The mill is evaluated for resilience under hefty use. It supplies dependable results over years.

Applications extend beyond food. Cosmetics companies utilize it for fine powders in make-up. Nanotechnology study counts on its precision. Environmental labs process soil samples for analysis. The maker adapts to diverse requirements.

Reduced noise operation fulfills workplace safety and security criteria. It produces a comfy environment for drivers. The grinding process remains efficient without loud disruptions. This machine integrates performance with practicality.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Nano Super Fine Powder Grinding Machine Ce Approved Grinder For Food Industry Research Low Noise Planetary Ball Mill

What particle size can the nano super fine powder grinding machine achieve?

The machine produces particles as small as 0.1 microns. This suits applications needing ultra-fine powders. It uses advanced planetary ball milling technology. The grinding process is efficient. It breaks down materials evenly.

Is the grinder safe for food industry use?

Yes. The machine is CE-certified. It meets strict safety and hygiene standards. All parts touching food are stainless steel. This prevents contamination. It works for spices, additives, and other food materials.

How loud is the machine during operation?

Noise levels stay below 60 decibels. This is quieter than typical industrial grinders. The design reduces vibration. It works well in labs or production areas. Workers avoid excessive noise exposure.

What maintenance does the grinding machine require?

Clean the grinding jars and balls after each use. Check the motor and belts monthly. Lubricate moving parts every 200 hours. Replace worn parts quickly. This keeps performance stable.

Why choose a planetary ball mill for research?

It offers precise control over speed and time. Different materials can be tested. The low-noise design suits lab environments. Results are repeatable. It handles small batches for experiments.

(Nano Super Fine Powder Grinding Machine Ce Approved Grinder For Food Industry Research Low Noise Planetary Ball Mill)

REQUEST A QUOTE

RELATED PRODUCTS

Custom ZG Mn13-1 high manganese steel cement ball mill liner plates

Low worth buying products Mining Grinding Mill Trommel Scrubber Wear Parts Rubber Ball Mill Liner For

Whole : durable 400*600 600*800 900×1800 Ball Mill Mining Ball Mill

Customized Mining Machine Parts Main Auxiliary Rotary Kiln Ball Mill Pinion Device Large Spur Big Helical Gear Shaft Assembly

Overflow ball mill Mining Equipment Machine s/Grinding Mill/Rod Mill for Hematite, Iron Ore, Bentonite, Limestone, Cement