Ball Mill Spare Parts

Competitive Wear Resistant Steel Casting Liner Plates for Crusher Machinery OEM Ball Mill Wear Parts

Small Ball Mill Grinding Machine with New Motor Core Component Ball Mill Spare Parts

Part of Ball Mill End Cover Mining Mine Mill Grinding Equipment Machinery Spare Parts

Ball Mill Machine Gold Mining Ball Mill Spare Parts Equipment Portable Ceramic Ball Mill for Mining

Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts

heavy duty mining ball mill spare part 42CrMo steel hollow shaft

Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding

ball mill parts liner plates sag mill liners / ball mill rubber liner

Wear resistant non-standard Heavy Machinery Ball Mill Parts large Casting Liner Plate

Liner bolts nuts sealing washers Ball mill Spare Part

Low worth buying products Mining Grinding Mill Trommel Scrubber Wear Parts Rubber Ball Mill Liner For

Overflow ball mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement

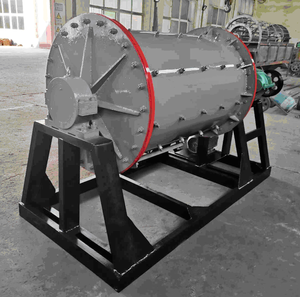

Overview of Heavy Machinery Round Mill Spare Components

Ball mills are necessary in different sectors for grinding products right into great powders. Trick spare components consist of liners, grinding media (balls), bearings, gears, and seals. These parts must be durable to hold up against the severe deterioration from the constant procedure. Premium extra parts ensure optimum performance, reduced downtime, and extended tool life.

Features of Heavy Machinery Sphere Mill Spare Components

- Toughness: Made from high-strength alloys resistant to wear and corrosion.

- Efficiency: Developed to improve grinding efficiency and minimize energy intake.

- Compatibility: Tailored to fit details models of round mills.

- Relieve of Replacement: Elements are created for quick and straightforward installment.

- Personalization: Offered in various specs to fulfill different functional requirements.

Specifications Table of Heavy Machinery Ball Mill Spare Parts

| Part Name | Material | Temperature Resistance | Application Area | Replacement Frequency |

|---|---|---|---|---|

| Liners | Manganese Steel | Up to 300°C | Mining, Cement | As needed |

| Grinding Media | Alloy Steel | Up to 200°C | Various | Annually |

| Bearings | Bronze | Up to 150°C | Chemical Processing | Semi-annually |

| Gears | Heat-treated Steel | Up to 250°C | Power Generation | Every 2 years |

| Seals | Ceramic | Up to 400°C | General Use | Quarterly |

Applications of Heavy Machinery Sphere Mill Spare Parts

- Mining: For grinding ores and minerals.

- Cement Market: Made use of in the manufacturing of cement clinker.

- Chemical Handling: In the manufacturing of chemicals requiring fine grinding.

- Power Generation: For coal pulverization in thermal nuclear power plants.

- Firm Intro: Excavator Add-ons

Company Introduction

Excavator Attachments specializes in providing high-quality heavy machinery spare parts, including those for ball mills. With a commitment to excellence, they offer durable and efficient solutions tailored to meet the unique needs of their clients. Their extensive product range and customer-centric approach have made them a trusted name in the industry.

5 FAQs of Heavy Machinery Sphere Mill Spare Parts

What products are Sphere Mill spare components made of?

Typically, they are made from steel alloys that provide resistance to use and high temperatures.

How typically should spare components be replaced?

This depends upon use and ecological conditions, yet regular evaluations can assist in figuring out when replacements are essential.

Can saving parts improve the efficiency of my round mill?

Yes, using top-notch, well-fitted extra components can considerably enhance performance and power performance.

Where can I acquire reliable spare components?

From original device producers or trustworthy suppliers like Excavator Attachments.

Are customized parts readily available?

Yes, numerous suppliers provide modification solutions to fit details needs.