PRODUCT PARAMETERS

Description

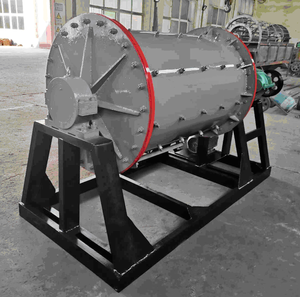

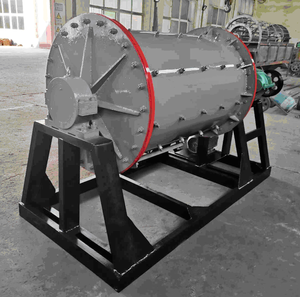

Brief introduction of Part of Ball Mill End Cover Mining Mine Mill Grinding Equipment Machinery Spare Parts

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Part of Ball Mill End Cover Mining Mine Mill Grinding Equipment Machinery Spare Parts refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Part of Ball Mill End Cover Mining Mine Mill Grinding Equipment Machinery Spare Parts

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Part of Ball Mill End Cover Mining Mine Mill Grinding Equipment Machinery Spare Parts)

Specification of Part of Ball Mill End Cover Mining Mine Mill Grinding Equipment Machinery Spare Parts

The ball mill end cover is an essential component in the operation of a mine or processing plant, responsible for protecting the grinding equipment from damage and maintaining optimal performance. This cover features durable materials such as stainless steel, providing maximum resistance to wear and tear.

The specification of the ball mill end cover includes its size, shape, and material. The size refers to the dimensions of the cover, which should be appropriate for the size of the ball mill and ensure adequate protection for both the equipment and the worker. The shape may vary depending on the type of cover being used, but it should be designed with stability in mind to prevent it from during operation.

The material selection also plays a critical role in the durability and effectiveness of the ball mill end cover. Stainless steel is commonly used due to its strength, corrosion resistance, and ease of cleaning. However, other materials such as aluminum or polypropylene can also be used, depending on the specific requirements of the application.

Once the ball mill end cover has been specified, it must be properly installed and maintained to ensure optimal performance and longevity. This includes regular inspections and cleaning to remove debris and keep the cover free of rust and corrosion. Proper lubrication of moving parts can also help to prolong the life of the cover and minimize maintenance required.

In conclusion, the specification of the ball mill end cover is crucial for ensuring optimal performance and longevity of the mining machine. By selecting the right size, shape, and material, and properly installing and maintaining the cover, operators can minimize downtime and maximize productivity in their operations.

(Part of Ball Mill End Cover Mining Mine Mill Grinding Equipment Machinery Spare Parts)

Applications of Part of Ball Mill End Cover Mining Mine Mill Grinding Equipment Machinery Spare Parts

Part of ball mill end cover mining mine mill grinding equipment machinery spare parts is an essential component that ensures the efficient and safe operation of ball mills in mining operations. These parts provide wear protection to the moving parts of the ball mill, extending their service life and reducing maintenance costs.

Ball mill end covers play a crucial role in preventing damage to the balls as they pass through the rotating cylinder. The covers typically consist of metal plates or gaskets that fit over the ends of the balls, reducing friction between them and preventing them from slipping out of the gearbox and causing premature wear.

In addition to providing wear protection, part of ball mill end cover mining mine mill grinding equipment machinery spare parts also helps prevent debris from entering the ball mill and damaging the bearings. The covers can be designed with gaps between the plates that allow air to flow through, preventing moisture buildup and dust accumulation.

Overall, part of ball mill end cover mining mine mill grinding equipment machinery spare parts is a critical component that helps ensure the proper functioning of ball mills in mining operations. Its durability and effectiveness make it an important investment for operators looking to optimize the performance of their equipment.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Part of Ball Mill End Cover Mining Mine Mill Grinding Equipment Machinery Spare Parts

1. What is the function of the ball mill end cover?

The ball mill end cover serves as a protective layer around the balls and liner plates, preventing them from coming into contact with each other and causing damage during operation.

2. How does the ball mill end cover prevent dust accumulation?

The ball mill end cover is designed to trap dust particles and prevent them from entering the operating area, which can cause respiratory problems for workers in enclosed spaces.

3. Why is it important to replace the ball mill end cover regularly?

Regular replacement of the ball mill end cover ensures that there is no buildup of dust or debris on the surface, reducing the risk of overheating and damaging the grinding equipment.

4. What types of spare parts are available for the ball mill end cover?

There are different types of spare parts available for the ball mill end cover, including covers, bushings, bolts, and nuts, depending on the specific model and manufacturer of the machine.

5. Can I purchase spare parts online for the ball mill end cover?

Yes, many spare parts for the ball mill end cover can be purchased online through various retailers and online marketplaces. It’s important to check the availability and pricing before making a purchase to ensure that you get the best deal.

(Part of Ball Mill End Cover Mining Mine Mill Grinding Equipment Machinery Spare Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Mining Equipment Spares Hollow Shaft Discharge Shaft for Ball Mill

Ceramic Liner Ball Mill Machine Ball Grinding Mill Small Laboratory Ball Mill From

Factory custom mining equipment ball mill drive parts accessories Hollow shaft

Crusher Plant Parts Ball Mill Grid Plate Grinding Steel Balls Liner Plate For Ball Mill Crusher Parts

Gold Ore Lead Zinc Copper Mining Stone Mini Steel Coal Steel Used Wet Ball Mill and Dry Ball Mill for Mining Grinding