PRODUCT PARAMETERS

Description

Brief introduction of s Large diameter ball mill bull gear forging ZG45 cement rotary kiln spur girth ring

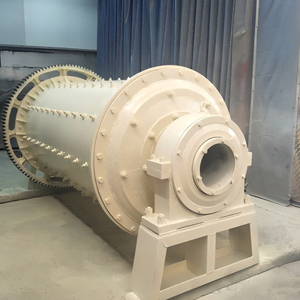

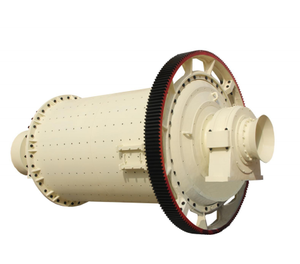

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. s Large diameter ball mill bull gear forging ZG45 cement rotary kiln spur girth ring refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of s Large diameter ball mill bull gear forging ZG45 cement rotary kiln spur girth ring

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(s Large diameter ball mill bull gear forging ZG45 cement rotary kiln spur girth ring)

Specification of s Large diameter ball mill bull gear forging ZG45 cement rotary kiln spur girth ring

The large diameter sphere mill bull equipment forging, produced from ZG45 product, is a critical part created for cement rotary kiln spur girth ring applications. This sturdy gear is crafted to deliver extraordinary efficiency under high-stress problems, making sure dependable power transmission in demanding commercial environments. The ZG45 alloy, a high-strength cast carbon steel, supplies exceptional mechanical residential or commercial properties, including excellent wear resistance, toughness, and tiredness stamina, making it suitable for extended operation in rough and high-load setups.

Trick specs consist of a typical external diameter varying from 3 meters to 8 meters, with module sizes in between 20 and 40, customized to match specific mill or kiln needs. The face width of the equipment differs from 400 mm to 800 mm, making certain ideal contact with the pinion equipment for efficient torque transfer. The tooth account is precision-machined to AGMA or ISO requirements, ensuring smooth meshing, minimized resonance, and minimal sound throughout procedure. Warmth therapy processes such as normalizing and tempering are related to achieve a solidity series of 200-250 HB, improving resilience while preserving resistance to influence and deformation.

The bull equipment is cast as a solitary item to get rid of powerlessness, followed by ultrasonic screening and magnetic fragment inspection to discover interior defects. Surface solidifying strategies, consisting of induction solidifying, might be put on the tooth flanks to reach a surface firmness of 45-50 HRC, more prolonging service life. Mounting surface areas are machined to limited resistances (IT8-IT9) to ensure correct placement with the rotating kiln or sphere mill covering.

Made for cement production, this equipment withstands extreme temperature levels, dirt, and constant rotational stress and anxieties. It sustains rotational speeds of as much as 25 RPM and torque capacities surpassing 1,000 kNm. Personalization choices include bolt-hole patterns, keyway configurations, and flange designs to incorporate perfectly with existing systems. Conformity with worldwide standards such as ISO 6336 and ASTM A148 makes sure high quality and interoperability. Normal upkeep, including lubrication and placement checks, is advised to make the most of functional lifespan.

(s Large diameter ball mill bull gear forging ZG45 cement rotary kiln spur girth ring)

Applications of s Large diameter ball mill bull gear forging ZG45 cement rotary kiln spur girth ring

The huge size ball mill bull gear forging made from ZG45 material is a vital component in durable commercial machinery, particularly in concrete manufacturing and associated markets. Designed for high-torque applications, this durable building works as the main drive component in ball mills and rotary kilns, ensuring reliable power transmission and reliable procedure sought after environments.

In concrete production, the ZG45 bull gear is integral to ball mills, which grind raw materials like sedimentary rock, clay, and iron ore into fine powder, along with pulverize clinker to create concrete. Its big size suits hefty loads, making it possible for smooth turning and constant grinding effectiveness. The equipment’s spur layout guarantees specific meshing with pinion equipments, decreasing energy loss and vibration. Concurrently, in cement rotating kilns, the spur girth ring (or girth gear) is installed on the kiln shell to help with rotational activity during the calcination process. The ZG45 material’s high carbon content (about 0.45%) supplies extraordinary tensile strength, use resistance, and effect strength, essential for holding up against extreme mechanical anxieties, thermal fluctuations, and rough problems.

ZG45’s premium performance is better improved through heat therapy processes like relieving and toughening up, which optimize solidity and fatigue resistance. This makes sure prolonged service life also under constant operation. The gear’s accurate design assurances exact placement with mating elements, reducing wear on gear teeth and lowering upkeep prices.

Past cement, this creating locates applications in mining, metallurgy, and chemical sectors, where huge rotating devices is used for product processing. Its sturdiness and load-bearing capability make it optimal for crushing, grinding, and mixing procedures.

By combining ZG45’s material advantages with innovative building methods, the big diameter bull equipment supplies unequaled integrity, reducing downtime and functional prices. Its role in preserving smooth industrial procedures emphasizes its significance in fields reliant on heavy equipment, cementing its condition as a keystone of modern manufacturing and processing facilities.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of s Large diameter ball mill bull gear forging ZG45 cement rotary kiln spur girth ring

**1. What is ZG45 material, and why is it used for large diameter ball mill bull gear forgings?**

ZG45 is a high-strength cast steel with excellent mechanical properties, including good wear resistance, toughness, and load-bearing capacity. It is specifically chosen for large-diameter bull gears and girth rings in cement rotary kilns and ball mills due to its ability to withstand heavy operational loads, high torque, and harsh environments like extreme temperatures and abrasion. ZG45’s durability ensures long-term reliability in cement production, reducing downtime and maintenance costs.

**2. How is the forging process critical for spur girth ring performance?**

Forging enhances the metallurgical structure of ZG45 steel, eliminating internal defects and improving grain flow. This results in superior fatigue resistance, impact strength, and uniform hardness distribution. Forged bull gears and girth rings are less prone to cracking or deformation under cyclic stresses, ensuring precise meshing with pinions and smooth rotation of kilns or mills. The process also allows customization of gear teeth profiles for optimal load distribution and minimal wear.

**3. What are the key design features of a cement rotary kiln spur girth ring?**

A spur girth ring for cement rotary kilns is designed with a large diameter (often exceeding 5 meters) to handle rotational forces and radial loads. Key features include precision-machined teeth for smooth engagement, balanced weight distribution to prevent vibration, and surface hardening treatments like quenching and tempering to enhance wear resistance. Flange mounting holes and robust structural integrity ensure secure attachment to the kiln shell.

**4. How does proper alignment affect bull gear and girth ring longevity?**

Misalignment between the bull gear and pinion causes uneven load distribution, leading to premature wear, pitting, or tooth breakage. Proper alignment minimizes stress concentrations, reduces vibration, and ensures efficient power transmission. Regular laser alignment checks during installation and maintenance are critical to extending the gear’s service life and preventing unplanned shutdowns in cement plants.

**5. What maintenance practices are recommended for large-diameter ball mill gears?**

Routine inspections for wear patterns, lubrication quality, and bolt tightness are essential. Use high-viscosity, extreme-pressure grease to reduce friction and heat. Monitor backlash and tooth contact patterns periodically. Address minor wear through timely re-machining or surface welding. Avoid overloading the mill, and ensure the gear is protected from dust and moisture to prevent corrosion. Proactive maintenance ensures optimal performance and a lifespan of 10–15 years.

(s Large diameter ball mill bull gear forging ZG45 cement rotary kiln spur girth ring)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Factory Supply Mining Cement limestone powder rotary dry wet gold copper ore Grinding Ball Mill

High crushing ratio 5 10 15 tons per hour cement mineral grinding ball mill with spare parts for gold silver copper crushing

Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500