PRODUCT PARAMETERS

Description

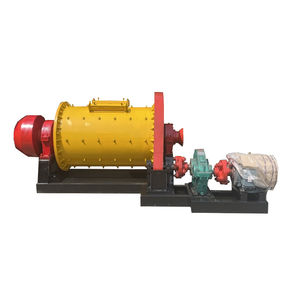

Brief introduction of Tanzania Competitive s ball mill steel balls Alumina Ball Mill For Gold Mining

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Tanzania Competitive s ball mill steel balls Alumina Ball Mill For Gold Mining refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Tanzania Competitive s ball mill steel balls Alumina Ball Mill For Gold Mining

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Tanzania Competitive s ball mill steel balls Alumina Ball Mill For Gold Mining)

Specification of Tanzania Competitive s ball mill steel balls Alumina Ball Mill For Gold Mining

** Tanzania Competitive Steel Balls & Alumina Ball Mill for Gold Mining **.

Our high-performance steel spheres and alumina grinding media are crafted for gold mining operations, providing longevity and effectiveness. Developed for sphere mills, these grinding media make certain optimal dimension decrease, enhancing gold recovery rates.

** Trick Requirements: **.

– ** Product: ** High-chrome steel (HRC 58-65) and 92% alumina ceramic.

– ** Sizes: ** Steel spheres (20mm– 120mm); Alumina rounds (5mm– 50mm).

– ** Hardness: ** Steel (≥ 58 HRC); Alumina (≥ 9 Mohs).

– ** Thickness: ** Steel (7.8 g/cm ³); Alumina (3.6 g/cm ³).

** Advantages: **.

– ** Wear Resistance: ** High-chrome steel withstands abrasion, decreasing substitute frequency.

– ** Corrosion Resistance: ** Alumina spheres grow in acidic/alkaline slurries.

– ** Energy Performance: ** Attire form minimizes energy usage.

** Applications: ** Perfect for grinding gold ore in ball mills, accomplishing fine particle sizes for improved cyanidation/leaching.

** Personalized: ** Available in tailored sizes and materials to fit certain ore hardness and mill conditions.

** Compliance: ** Fulfills ISO 9001 criteria for consistent high quality and efficiency.

Enhance gold recuperation with resilient, high-performance grinding media customized for Tanzania’s mining demands.<|end▁of▁sentence|>

(Tanzania Competitive s ball mill steel balls Alumina Ball Mill For Gold Mining)

Applications of Tanzania Competitive s ball mill steel balls Alumina Ball Mill For Gold Mining

Tanzania’s Affordable S Round Mill Steel Spheres and Alumina Sphere Mills are essential elements in gold mining operations, offering sturdiness and efficiency in ore processing. These steel balls, crafted for high-impact grinding, make certain optimal dimension decrease of ore, enhancing gold healing prices. Their wear-resistant residential properties lower replacement frequency, decreasing operational prices.

Alumina ceramic rounds, understood for exceptional firmness and rust resistance, are optimal for grinding abrasive products in gold mining. Their high density makes certain effective grinding, minimizing energy intake. These spheres lessen contamination, important for keeping ore purity.

In Tanzania’s gold mining market, these grinding media enhance crushing efficiency, minimize downtime, and lower functional costs. Their robustness in harsh mining settings makes sure trusted efficiency, making them important for taking full advantage of gold removal effectiveness.<|end▁of▁sentence|>

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Tanzania Competitive s ball mill steel balls Alumina Ball Mill For Gold Mining

**FAQs for Tanzania Competitive Ball Mill Steel Balls & Alumina Balls for Gold Mining**

**1. What are the advantages of steel balls vs. alumina balls in gold mining?**

Steel balls offer high density and durability, ideal for coarse grinding. Alumina balls are corrosion-resistant and ideal for fine grinding, reducing contamination in gold processing.

**2. How long do these grinding balls last in a gold mining mill?**

Lifespan depends on material and usage. Steel balls last 3–6 months; alumina balls can last 12+ months due to high wear resistance.

**3. Are these grinding media cost-effective for Tanzanian miners?**

Yes. High-quality steel/alumina balls reduce replacement frequency and downtime, lowering long-term costs despite higher initial costs.

**4. Are these balls suitable for Tanzania’s gold ore processing?**

Yes. Designed for high-impact grinding, they efficiently process hard gold ores common in Tanzania, ensuring optimal mineral recovery.

**5. How is shipping handled for Tanzanian buyers?**

Suppliers offer reliable shipping (air/sea) to major Tanzanian ports. Lead times vary but prioritize safe, timely delivery to mining sites.<|end▁of▁sentence|>

(Tanzania Competitive s ball mill steel balls Alumina Ball Mill For Gold Mining)

REQUEST A QUOTE

RELATED PRODUCTS

Mining ball mill chromium molybdenum alloy liner vulnerable parts, large cast steel spare parts, new product mill liner

Overflow ball mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement

Effective Large Capacity Ball.Mill Ball Mill For Mining

Ball mill spare parts Ball mill ring gear and gears Ball mill Gears

Coal mill in thermal power plant centrifugal fan oil filter element spare parts ball mill coal mill to generate electricity