PRODUCT PARAMETERS

Description

Brief introduction of Wet Small Ball Mill Grinding Machine Spare Parts for in Zimbabwe

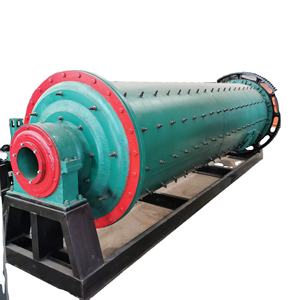

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Wet Small Ball Mill Grinding Machine Spare Parts for in Zimbabwe refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Wet Small Ball Mill Grinding Machine Spare Parts for in Zimbabwe

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Wet Small Ball Mill Grinding Machine Spare Parts for in Zimbabwe)

Specification of Wet Small Ball Mill Grinding Machine Spare Parts for in Zimbabwe

Wet small ball mill grinding machine spare parts can be critical components in ensuring the proper functioning and longevity of the machine. The Specification of these spare parts helps to ensure that they meet the necessary requirements for use in wet small ball mill grinding machines in Zimbabwe.

In addition to providing an overview of the specification, it is important to consider the specific needs and requirements of the wet small ball mill grinding machine in question. This includes information on size, weight, and dimensions of the spare parts, as well as their intended function within the overall system.

It is also important to consider any relevant standards or regulations that apply to the wet small ball mill grinding machine in Zimbabwe. For example, there may be specific requirements for the replacement of certain spare parts, or for the condition and age of the machine before new parts can be installed.

When specifying wet small ball mill grinding machine spare parts, it is also important to take into account the availability and cost of the required components. This may involve researching suppliers or manufacturers who specialize in producing these types of parts, or negotiating with suppliers to get the best possible prices.

Overall, the Specification of wet small ball mill grinding machine spare parts is an important aspect of ensuring that the machine continues to operate effectively and efficiently. By carefully considering the specific needs and requirements of the machine, as well as the availability and cost of the required components, it is possible to select the most appropriate spare parts for your wet small ball mill grinding machine in Zimbabwe.

(Wet Small Ball Mill Grinding Machine Spare Parts for in Zimbabwe)

Applications of Wet Small Ball Mill Grinding Machine Spare Parts for in Zimbabwe

Wet small ball mill grinding machine spare parts are essential components that ensure smooth and efficient operation of the wet small ball mill. These parts play a critical role in maintaining the integrity of the mill and ensuring its longevity.

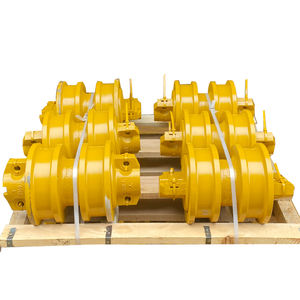

Wet small ball mill grinding machine spare parts can be purchased from various manufacturers and suppliers across the globe. The types of spare parts available may vary depending on the model of the mill, but some common components include the grinding balls, rod bearings, bowl liner, and separator.

Grinding balls are used to reduce the size of the crushed materials by friction with the grinding media. They can be made of steel or ceramic and come in different sizes to suit the specific requirements of the mill. Rod bearings are used to provide support for the rotating equipment and prevent it from slipping. Bowl liners are used to protect the grinding medium from damage caused by abrasive particles and maintain a consistent flow of material. Separators are used to remove impurities and unwanted particles from the ground material before it is fed into the next stage of the process.

To ensure proper functioning of the wet small ball mill, it is important to purchase high-quality spare parts that are made of durable materials and designed specifically for the mill’s specifications. Regular maintenance of the mill, including cleaning and lubrication of all moving parts, can also help prolong its lifespan and improve its efficiency.

In conclusion, wet small ball mill grinding machine spare parts are essential components that contribute significantly to the overall performance and functionality of the mill. By purchasing high-quality spare parts, manufacturers and suppliers can ensure that the mill operates efficiently and effectively, providing a reliable solution for customers in Zimbabwe.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Wet Small Ball Mill Grinding Machine Spare Parts for in Zimbabwe

1. What is the recommended replacement interval for wet small ball mill grinding machine spare parts in Zimbabwe?

The recommended replacement interval for wet small ball mill grinding machine spare parts in Zimbabwe depends on several factors such as usage frequency, material properties, and environmental conditions. It is best to consult with the manufacturer or supplier for specific recommendations on how often to replace the spare parts.

2. How should I maintain my wet small ball mill grinding machine to ensure optimal performance?

To maintain your wet small ball mill grinding machine for optimal performance, it is important to follow these guidelines:

a) Clean the machine regularly to prevent buildup of particles and other contaminants.

b) Check the bearings and other moving parts for wear and tear and replace them promptly if necessary.

c) Regularly lubricate the machine’s moving components to reduce friction and prolong their lifespan.

d) Keep the operating temperature below 40°C and avoid overheating by turning off the machine when not in use.

e) Follow the manufacturer’s instructions for proper storage and transportation of the machine.

By following these maintenance tips, you can help extend the life of your wet small ball mill grinding machine and ensure its continued operation at peak efficiency.

(Wet Small Ball Mill Grinding Machine Spare Parts for in Zimbabwe)

REQUEST A QUOTE

RELATED PRODUCTS

Ball mill spare parts Ball mill ring gear and gears Ball mill Gears

Hot ISO CE Certified Large Cast Steel Ball Mill Cylinder Liner Plates High Nicr Alloy Mill Liner Bearing Engine Motor Spare

OEM ball mill split external cement machinery parts spur large segment ring gear crown ring gear large ring gear

Customized Various Sizes Rotary Kiln Spare Parts Cement Ball Mill Drive Large Casting Gears

High manganese casting ball mill parts mill impact liner plate and blow bar