PRODUCT PARAMETERS

Description

Introduction to towed Customized Good Various excavator Track Assembly Track Shoe Pad excavator spare parts For

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Customized Good Various excavator Track Assembly Track Shoe Pad excavator spare parts For refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Customized Good Various excavator Track Assembly Track Shoe Pad excavator spare parts For

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Customized Good Various excavator Track Assembly Track Shoe Pad excavator spare parts For )

Specification of Customized Good Various excavator Track Assembly Track Shoe Pad excavator spare parts For

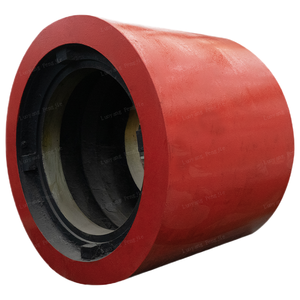

Customized Excellent Various Excavator Track Assembly Track Shoe Pad Excavator Spare Parts are precision-engineered elements designed to improve the durability, performance, and adaptability of excavators in demanding atmospheres. These track shoes are important for distributing the machine’s weight uniformly, lowering ground pressure, and making certain stability across diverse surfaces. The product is tailored to fulfill specific demands, guaranteeing compatibility with various excavator brand names and designs, consisting of Caterpillar, Komatsu, Hitachi, Volvo, and others.

** Product & Construction: ** Produced utilizing premium alloy steel or manganese steel, these track footwear undergo sophisticated warm therapy processes to accomplish outstanding solidity (normally HRC 40-60) and wear resistance. Surface area therapies like carburizing or satiating better enhance durability, expanding life span also under heavy tons, unpleasant soils, or rocky conditions.

** Customization Alternatives: ** Track shoe pads can be personalized in dimension, density, and tread pattern to match details applications. Common arrangements include flat, single-grouser, double-grouser, or triple-grouser layouts, enhanced for mud, snow, asphalt, or tough landscapes. Screw hole patterns, pin diameters, and shoe widths are adjusted to straighten with OEM specifications or special equipment needs.

** Efficiency Features: ** These footwear are engineered to lessen slippage, minimize undercarriage wear, and enhance grip. Precision machining makes certain seamless integration with track chains, rollers, and sprockets, reducing resonance and noise during operation. Optional solidified inserts or changeable lugs give cost-effective upkeep options.

** Applications: ** Ideal for building, mining, forestry, and agricultural projects where terrain tests demand dependable undercarriage elements. They endure severe temperature levels, corrosion, and influence pressures, making certain regular efficiency in wet, sloppy, or rough atmospheres.

** Quality Assurance: ** Each track shoe goes through rigorous screening, including solidity checks, dimensional assessments, and load-bearing simulations, to ensure compliance with global requirements (ISO, CE). Customized batches are sustained by thorough documentation, consisting of product qualifications and warmth therapy records.

** Preparation & Assistance: ** Custom orders normally call for 15-30 days for production, depending on style intricacy. Technical support is readily available for sizing, installation guidance, and troubleshooting. Compatible with both new and refurbished track settings up, these footwear offer an affordable service to expand devices lifespan and decrease downtime.

(Customized Good Various excavator Track Assembly Track Shoe Pad excavator spare parts For )

Applications of Customized Good Various excavator Track Assembly Track Shoe Pad excavator spare parts For

Custom-made excavator track footwear, likewise called track pads, are essential elements developed to boost the performance, sturdiness, and adaptability of excavators throughout varied industries. These specialized components form the interface in between the excavator’s undercarriage and the ground, making certain security, traction, and effective activity in difficult atmospheres. Their applications extend industries where terrain, product, and functional demands differ substantially.

In building and construction, personalized track shoes optimize excavator performance on combined surfaces such as rough surfaces, loosened soil, or urban work websites. Enhanced styles with high-carbon steel or alloy materials protect against early wear, while hostile walk patterns boost hold on uneven ground. For extracting procedures, track shoes are customized to endure rough conditions, frequently integrating hardened surface areas or tungsten carbide coverings to stand up to damages from sharp rocks and heavy lots. This customization reduces downtime and extends component life in high-stress settings.

Farming and forestry applications gain from track footwear made for soft, muddy surface. Bigger pads disperse the machine’s weight, decreasing ground pressure to stop dirt compaction and sinkage. In demolition or reusing websites, track footwear are enhanced to endure punctures from particles like rebar or concrete pieces, ensuring safety and security and functional continuity.

Personalization also addresses climate-specific obstacles. Arctic procedures use track shoes with deep lugs for icy surface areas, while exotic environments utilize corrosion-resistant coatings to combat dampness and moisture. Compatibility with different excavator versions guarantees seamless assimilation, whether for small mini-excavators or large mining rigs.

The advantages of personalized track footwear include extended life-span, reduced upkeep expenses, and improved fuel efficiency as a result of reduced slippage. Operators gain enhanced control and security, decreasing crash threats from track instability. By picking tailored layouts, organizations achieve lasting expense financial savings and operational integrity, making customized track footwear a tactical investment for making best use of excavator efficiency in any application.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Customized Good Various excavator Track Assembly Track Shoe Pad excavator spare parts For

1. **What customization options are available for excavator track shoe pads?**

Customized excavator track shoe pads can be tailored to fit specific excavator models, brands, and operating conditions. Options include adjusting the size (length, width, thickness), material grade (standard or high-carbon steel for enhanced durability), tread pattern (single, double, or triple grouser designs), and additional features like reinforced edges or anti-wear coatings. Custom logos or part numbers can also be engraved for identification.

2. **How do I ensure compatibility with my excavator model?**

Provide your excavator’s make, model, and serial number, along with the existing track shoe pad’s dimensions (bolt hole spacing, overall length/width) and tread pattern. Reputable suppliers use this data to match or reverse-engineer parts for precise fitment. Compatibility is critical to avoid uneven wear, track misalignment, or equipment damage.

3. **What materials are used in customized track shoe pads?**

High-quality track shoe pads are typically made from manganese steel (Mn13, Mn18) or boron alloy steel for superior hardness and impact resistance. Some applications use heat-treated carbon steel for a balance of strength and cost-effectiveness. Surface treatments like quenching, tempering, or chrome plating may be added to reduce abrasion and extend service life in harsh terrains.

4. **How long do customized track shoe pads last compared to OEM parts?**

Durability depends on material quality, design, and operating conditions (e.g., rocky vs. muddy terrain). Well-made customized pads using premium materials often match or exceed OEM lifespan, lasting 1,500–2,500 hours under normal use. Proper maintenance (regular cleaning, tension checks) and avoiding overload scenarios further enhance longevity.

5. **What is the typical lead time for custom orders?**

Lead times vary based on design complexity and order volume but generally range from 15–30 days after finalizing specifications. Suppliers with in-house casting/forging facilities streamline production. Urgent orders may be expedited for an additional fee. Always confirm timelines and quality certifications (ISO, CE) before placing bulk orders.

(Customized Good Various excavator Track Assembly Track Shoe Pad excavator spare parts For )

REQUEST A QUOTE

RELATED PRODUCTS

Undercarriage spare parts For excavator And Bulldozer Undercarriage

Factory Supply Teeth Cheep Durable Two-side guard block 60-195 Excavator guard blocks

Crawler Excavator Final Drive Travel Gearbox Planetary Gear Carrier Assy Swing Reduction Gearbox Reducer

E10 Series Undercarriage Part Top Carrier Roller Idler Track Bottom Roller Drive Sprocket For Bobcat Mini Excavator Spare Parts

hydraulic breaker spare parts excavator