PRODUCT PARAMETERS

Description

Introduction to towed Digger Attachments excavator Rotating Grabber For

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Digger Attachments excavator Rotating Grabber For refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Digger Attachments excavator Rotating Grabber For

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

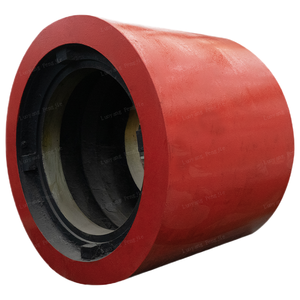

(Digger Attachments excavator Rotating Grabber For )

Specification of Digger Attachments excavator Rotating Grabber For

The revolving grabber for excavators is created to deal with materials like logs, scrap, rocks, and particles. It attaches to excavators to boost effectiveness in demolition, reusing, and material sorting. The grabber is developed with high-strength steel for longevity. It resists wear and handles hefty lots without bending. The hydraulic turning system enables 360-degree motion. Operators can place the grabber precisely in limited rooms. The rotation mechanism works efficiently under high pressure. It preserves security during operation.

The grabber can be found in sizes suitable excavators from 1 to 30 tons. It deals with mini excavators for tiny work and big makers for commercial jobs. Jaw choices include two or three claws. The jaws open wide to grasp irregular shapes. Maximum opening up sizes range from 500mm to 1500mm. Hydraulic stress requirements stay between 200 and 350 bar. This matches conventional excavator hydraulic systems. Load capacity varies from 0.5 to 3 tons. It depends on the excavator’s dimension and the grabber’s configuration.

Hardened steel teeth line the jaws. They permeate tough products. The teeth are changeable. This minimizes downtime and maintenance costs. A strengthened pivot joint links the grabber to the excavator arm. It manages high torque throughout rotation. Security attributes include pressure safety valve. These avoid overload damages. The valves redirect excess hydraulic pressure instantly.

Controls integrate with the excavator’s hydraulic circuits. No added systems are needed. Operators use the existing joystick to rotate, open, and shut the grabber. Optional attributes consist of quick couplers. These allow operators change in between add-ons fast. Personalized jaw pads are offered. They secure fragile products from scratches.

Applications include logging, scrap lawns, building and construction websites, and waste administration. The grabber raises, kinds, and transfers materials successfully. It does in harsh problems like rain, mud, and extreme temperature levels. Normal greasing of the rotation bearing is advised. This makes sure smooth procedure over time.

(Digger Attachments excavator Rotating Grabber For )

Applications of Digger Attachments excavator Rotating Grabber For

The excavator rotating grabber is a functional attachment designed for multiple tasks. It works with hydraulic excavators to manage products like logs, rocks, and debris. The turning attribute permits the grabber to turn 360 levels, making it simpler to place products precisely. This device enhances effectiveness in different markets due to its adaptability and stamina.

In building and construction and demolition, the rotating grabber lifts and moves hefty items. It gets steel beam of lights, concrete portions, or pipes safely. The rotation helps area materials exactly without rearranging the excavator. This conserves time during site cleaning or packing trucks. Demolition staffs use it to arrange recyclable materials from waste swiftly.

Waste administration and recycling operations benefit from this attachment. The grabber sorts via mixed particles, dividing steels, plastics, and wood. Its strong grasp holds irregularly formed items, decreasing slippage. Reusing plants use it to pack shredders or compactors effectively. The rotating feature enables drivers to pile products nicely in containers.

Forestry applications consist of handling logs and tree limbs. The grabber firmly clamps lumber throughout loading and dumping. It turns logs into the proper placement for reducing or transport. Landscapers utilize it to move huge rocks or uproot stumps. The attachment’s durability stands up to rough outside problems, making it reliable for heavy-duty tasks.

Ports and delivery lawns utilize revolving grabbers to handle bulk products. It loads and dumps freight like scrap steel or loose accumulations from ships. The 360-degree turning helps drivers reach limited spaces without moving the excavator. This quickens process in hectic logistics atmospheres.

The rotating grabber’s hydraulic system makes sure smooth operation under hefty tons. Replaceable teeth and enhanced jaws prolong its life expectancy. Operators control the grasp force to prevent damaging breakable materials. Personalized jaw dimensions adapt to different jobs, from taking care of little debris to huge stones. Its basic layout calls for minimal maintenance, minimizing downtime. This add-on is a functional option for markets requiring precise, efficient product handling.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Digger Attachments excavator Rotating Grabber For

What is a rotating grabber for excavators? A rotating grabber is an attachment designed to grab and handle materials. It connects to the excavator’s arm and rotates 360 degrees. This tool is used for picking up loose or bulky items like logs, rocks, or debris. It works in construction, demolition, and recycling. The rotation allows operators to position materials precisely without moving the entire machine.

How does the rotating grabber work? The grabber uses hydraulic power from the excavator. The operator controls the grabber’s jaws and rotation with the excavator’s joysticks. Hydraulic motors enable smooth rotation. The jaws clamp tightly to secure materials. This setup lets operators lift, rotate, and drop objects with accuracy. It requires basic hydraulic connections and compatible control systems.

What excavator models fit the rotating grabber? Most excavators with a standard hydraulic system can use rotating grabbers. Compatibility depends on weight capacity, arm size, and mounting brackets. Smaller grabbers suit compact excavators. Larger models fit heavy-duty machines. Check the attachment’s weight limit and required hydraulic flow. Manufacturers provide compatibility charts. Custom brackets or adapters may be needed for older machines.

What materials can the rotating grabber handle? It handles many materials. Common uses include logs, scrap metal, concrete chunks, and construction waste. The jaws grip uneven or slippery objects securely. Avoid overloading beyond the grabber’s weight limit. Sharp or extremely heavy materials may damage the jaws. Regular inspections ensure the grabber stays effective.

Is the rotating grabber easy to maintain? Maintenance is straightforward. Clean the grabber after use to prevent debris buildup. Check hydraulic hoses and connections for leaks. Lubricate rotating joints regularly to reduce wear. Inspect the jaws for cracks or damage. Replace worn parts quickly. Follow the manufacturer’s service schedule. Proper care extends the attachment’s lifespan and performance.

(Digger Attachments excavator Rotating Grabber For )

REQUEST A QUOTE

RELATED PRODUCTS

Excavator Track Links Assy Track Chain For Caterpillar (CAT) D4C Excavator Oil Track Chains 42Links Undercarriage Parts

Suitable CAT320C 360 330 235 120 Excavator Hydraulic Cylinder Arm Boom Bucket Cylinder For Caterpillar

Mini Excavator Hydraulic Repair Kit PC35 PC55 PC70 PC220 PC400-8 WA600-6 Main Piston Pump Parts For Komatsu

Factory Supply Teeth Cheep Durable Two-side guard block 60-195 Excavator guard blocks