PRODUCT PARAMETERS

Description

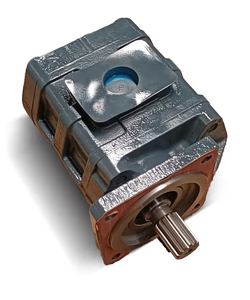

Introduction to towed Dragline Excavator Custom main drive pinion shaft Large Module Forged Transmission Parts bull gear Spur large gear Shaft

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Dragline Excavator Custom main drive pinion shaft Large Module Forged Transmission Parts bull gear Spur large gear Shaft refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Dragline Excavator Custom main drive pinion shaft Large Module Forged Transmission Parts bull gear Spur large gear Shaft

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Dragline Excavator Custom main drive pinion shaft Large Module Forged Transmission Parts bull gear Spur large gear Shaft)

Specification of Dragline Excavator Custom main drive pinion shaft Large Module Forged Transmission Parts bull gear Spur large gear Shaft

Dragline Excavators are heavy equipment used for construction and mining applications, and their main drives are critical components that help to power the excavator’s engine and move it forward. The specifications of these drives can vary depending on the type of dragline Excavator being used, but some common features include the following:

1. Main Drive Pinion shaft: A main drive pinion shaft is the component that connects the engine to the excavator’s front wheel. It typically has a diameter of around 25mm and is made from high-quality materials such as cast iron or steel.

2. Large Module Forged Transmission Parts: These transmission parts are used to transfer power between the main drive and other components in the dragline Excavator. They can include things like the transmission housing, torque converter, and transmission gears.

3. Bull Gear: A bull gear is an important component of the transmission system, providing smooth and reliable operation. It usually has a diameter of around 40mm and consists of several teeth that engage with the metal surfaces of the input and output shafts.

4. Spur Large Gear: A spur large gear is another important component of the transmission system. It has a spoke configuration and engages with the metal surfaces of the input and output shafts to transmit power. The size of the spur large gear will depend on the specific design of the transmission system.

These specification details will help ensure that your dragline Excavator’s main drive and transmission systems are functioning properly and efficiently. If you have any questions or concerns regarding the specifications of your particular dragline Excavator, please don’t hesitate to reach out to us. We would be happy to assist you with any questions or concerns you may have.

(Dragline Excavator Custom main drive pinion shaft Large Module Forged Transmission Parts bull gear Spur large gear Shaft)

Applications of Dragline Excavator Custom main drive pinion shaft Large Module Forged Transmission Parts bull gear Spur large gear Shaft

Dragline Excavators use customized main drive pinion shafts for their excavators, which provide efficient and reliable power transfer to the Excavator’s power source. These main drives are made from high-quality materials that ensure durability and longevity.

One of the benefits of using custom main drive pinion shafts is that they can be tailored to specific application requirements. For example, someExcavators may require more powerful increase their excavation capacity, while others may need smallers to maintain stability on uneven terrain.

Another benefit of custom main drive pinion shafts is that they offer greater flexibility in terms of power output. By using specialized components, manufacturers can create Pinions that can deliver both power and torque at different speeds, allowing Excavators to operate with greater ease and efficiency.

Additionally, custom main drive pinion shafts offer better performance than standard shafts. For example, they may have larger diameters or stronger tolerances, allowing them to handle more weight or withstand harsher conditions.

Overall, custom main drive pinion shafts are an essential component of Dragline Excavators. They provide efficient and reliable power transfer to the Excavator’s power source, while also offering greater flexibility and performance compared to standard shafts. Whether you’re looking to increase your Excavator’s excavation capacity or improve its stability on uneven terrain, a customized main drive pinion shaft is a top choice.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Dragline Excavator Custom main drive pinion shaft Large Module Forged Transmission Parts bull gear Spur large gear Shaft

1. What is a main drive pinion shaft?

A main drive pinion shaft is the component that converts mechanical torque from the excavator’s engine into linear motion, allowing it to move forward and backward in a straight line.

2. What is the purpose of the Large Module Forged Transmission Parts?

The Large Module Forged Transmission Parts are high-quality components designed specifically for use with a dragline excavator. These parts are made from durable materials and are engineered to withstand even the most demanding conditions, ensuring reliable performance and long-term reliability.

3. What is a bull gear?

A bull gear is a type of gear that is used in combination with a。,。

4. What is a spur gear?

A spur gear is another type of gear that is commonly used in the dragline excavator transmission system. It is a simple but effective way to reduce friction between the driving and non-driving gears, improving efficiency and reducing wear and tear on the equipment.

5. What are some potential issues that could arise when using the Large Module Forged Transmission Parts?

While these Large Module Forged Transmission Parts are designed to perform well, they may not be suitable for all types of excavators or operating conditions. It is important to carefully consider your specific needs and choose the appropriate components for your equipment before installation.

(Dragline Excavator Custom main drive pinion shaft Large Module Forged Transmission Parts bull gear Spur large gear Shaft)

REQUEST A QUOTE

RELATED PRODUCTS

Reliable Used Doosan Dragline Excavator for Focused on Core Components Gearbox and Bearing

Mehaton Heavy Duty Dragline Excavator Spare Parts CNC Machining Hot Long Spur Large Module Gear Rack Product Ring Gears

Engineering Parts for Repair Parts on Road Milling Machine,Paver, Rollers, Excavators, Loaders Factory Direct For Slaes

61NA-31320 Bucket Adapter Mini Excavator Undercarriage Heavy Equipment Spare Parts

Reliable Used Doosan Engine Core Components Cheap Dragline Excavator Big Savings Heavy Machinery Excavation Needs This Year